Application of Alumina Ceramic End Effectors in the Semiconductor Industry

Due to the extreme sensitivity of silicon wafers to contamination, wafer processing is typically carried out in a vacuum environment. In such conditions, most materials used for robotic arms are generally unsuitable for the task. The materials used for these arms need to be highly resistant to high temperatures, wear, and possess great hardness. Alumina ceramic meets these requirements perfectly, making it an excellent material for the manufacturing of robotic arms used in semiconductor equipment.

Characteristics of Alumina Ceramic End Effectors

(1)High Purity

The semiconductor industry demands materials of extremely high purity. Alumina ceramic end effectors are made from high-purity alumina, which effectively reduces the risk of contamination, ensuring the quality and performance of the products.

(2)Wear Resistance

During semiconductor manufacturing, end effectors frequently come into contact with various precision components. The wear resistance of alumina ceramic allows the end effectors to maintain stable performance during repeated operations, extending their service life.

(3)High Temperature Resistance

Semiconductor manufacturing involves high-temperature environments. Alumina ceramic end effectors can operate stably in such conditions without softening or structural deformation.

(4)Chemical Corrosion Resistance

In processes such as cleaning and etching, end effectors need to withstand exposure to various chemical liquids. The chemical corrosion resistance of alumina ceramic ensures its stability in harsh environments.

(5)Electrical Insulation

Alumina ceramic end effectors possess excellent electrical insulation properties, making them suitable for processes requiring current isolation, thereby ensuring the safety of semiconductor devices.

Applications of Alumina Ceramic End Effectors

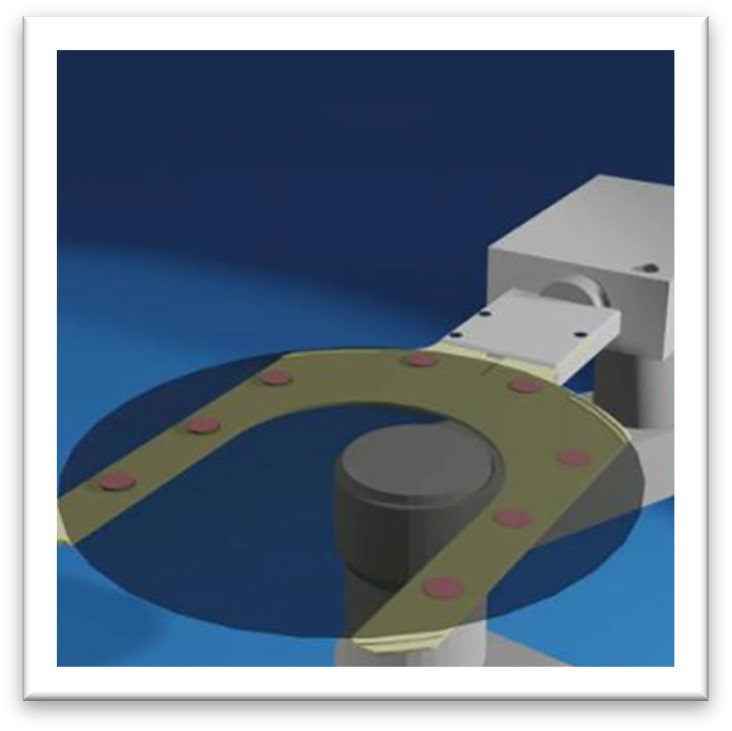

(1)Wafer Handling

Alumina ceramic end effectors are used for gripping, transporting, and placing wafers during wafer manufacturing and testing, especially in high-temperature or corrosive environments.

(2)Chip Pick-and-Place

During chip packaging, alumina ceramic end effectors are used to pick up chips from wafers and place them onto substrates or packages.

(3)Wire Bonding

In the wire bonding process of chip packaging, alumina ceramic end effectors can be used to precisely place and secure wires to connect the chip with external circuits.

(4)Inspection and Sorting

In the inspection and sorting of semiconductor devices, alumina ceramic end effectors are used to transfer devices from one location to the inspection equipment.

(5)Etching and Deposition Equipment

In the maintenance and operation of semiconductor equipment, alumina ceramic end effectors are used for handling and installing components in high-temperature or corrosive environments.

(6)Cleaning and Etching Processes

During wafer cleaning and etching processes, alumina ceramic end effectors can operate in chemical liquid environments without damage.

As a leading technical ceramics manufacturer, Xiamen Mascera Technology Co., Ltd. specializes in custom ceramic end effectors. The alumina handling arms currently produced are suitable for various high-performance semiconductor wafer handling applications, and their alumina ceramic components have received widespread approval from customers.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, boron nitride , aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.