Ceramic Substrate: Ideal for Automotive LiDAR Chip Packaging

LiDAR (Light Detection and Ranging) functions by emitting infrared laser signals and comparing the signals that are reflected back after encountering obstacles with the emitted signals to obtain information about the target's position, distance, orientation, speed, attitude, and shape. This technology enables obstacle avoidance or autonomous navigation. As a high-precision sensor, LiDAR is widely recognized as essential for achieving high-level autonomous driving, and its importance is increasingly highlighted.

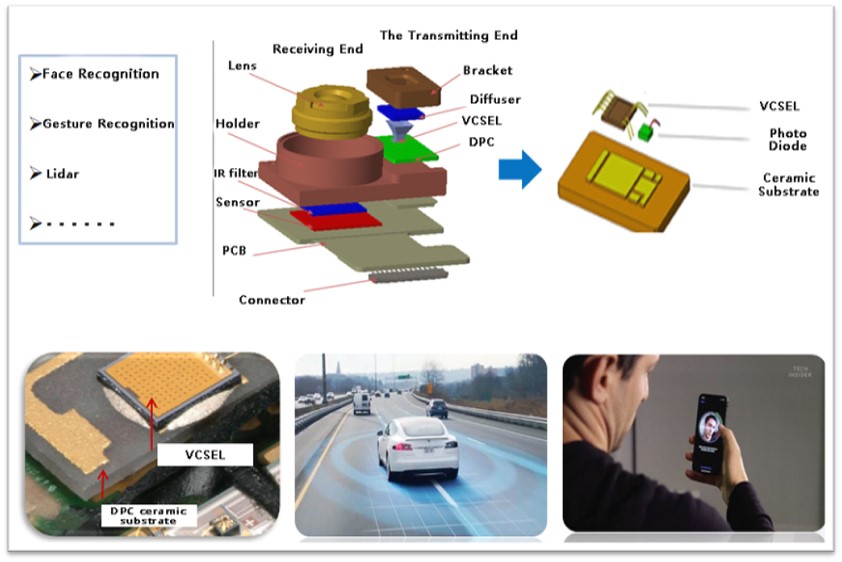

Among the core components of automotive LiDAR, the laser light source stands out. Currently, VCSEL (Vertical-Cavity Surface-Emitting Laser) sources are the preferred choice for automotive hybrid solid-state LiDAR and Flash LiDAR due to their low manufacturing cost, high reliability, small divergence angle, and ease of two-dimensional integration. VCSEL chips facilitate longer detection distances, higher perception accuracy, and compliance with stringent eye safety standards in automotive hybrid solid-state LiDAR. Additionally, they enable Flash LiDAR to achieve a more flexible and broader field of view with significant cost advantages.

However, the optical-to-electrical conversion efficiency of VCSELs is only 30-60%, which leads to challenges with heat dissipation and thermal-electrical separation. Additionally, VCSELs have a very high power density, exceeding one kilowatt per square millimeter, necessitating vacuum packaging. This requires the substrate to form a three-dimensional chamber with a lens mounted above the chip. Therefore, achieving efficient heat dissipation, thermal-electrical separation, and thermal expansion coefficient matching are important considerations when selecting VCSEL packaging substrates.

Ceramic substrates have emerged as the ideal chip packaging material for automotive LiDAR applications.

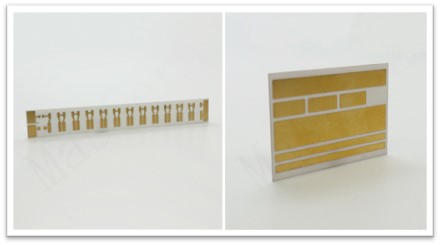

DPC (Direct Plated Copper) ceramic substrates offer high thermal conductivity, high insulation, high circuit precision, high surface flatness, and matching thermal expansion coefficients with the chip. They also provide vertical interconnectivity, which meets the packaging requirements of VCSELs.

1、Excellent Heat Dissipation

DPC ceramic substrates feature vertical interconnectivity, forming independent internal conductive channels. As ceramic is both an insulator and a heat conductor, it enables thermal-electrical separation, effectively addressing the heat dissipation issues of VCSEL chips.

2、High Reliability

The power density of VCSEL chips is very high, and thermal expansion mismatch between the chip and substrate can lead to stress problems. Ceramic substrates have a thermal expansion coefficient that matches well with VCSELs. Moreover, DPC ceramic substrates can form integrated metal frames and ceramic substrates into a sealed chamber, resulting in a compact structure with no intermediate bonding layers and high airtightness.

3、Vertical Interconnectivity

VCSEL packaging requires mounting lenses above the chip, necessitating a three-dimensional chamber in the substrate. DPC ceramic substrates offer the advantage of high-reliability vertical interconnectivity suitable for vertical eutectic bonding.

In the context of the development of automotive intelligence, ceramic materials play an increasingly important role in the intelligent development of new energy vehicles. As the foundation of the entire technology stack, continuous innovation in materials technology is essential for supporting the efficient development of the industry as a whole.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.