Comparison of Pyrolytic Boron Nitride and Hot pressed Boron Nitride

The chemical formula of boron nitride is BN, with a chemical composition of 43.6% boron and 56.4% nitrogen, with four different variants: hexagonal boron nitride (HBN), rhombohedral boron nitride (RBN), cubic boron nitride (CBN) and wurtzite boron nitride (WBN).

Hexagonal boron nitride H-BN is white, has good chemical stability and can resist the erosion of most molten metals. It has good self-lubricity, low hardness and easy machining.

The types of hexagonal boron nitride materials include:

1、Pyrolytic boron nitride PBN:99.99% boron nitride.

2、High purity boron nitride HPBN: > 98.5% boron nitride + boron oxide.

3、Calcium borate CABN: > 97.5% boron nitride + calcium borate.

4、Aluminum nitride boron nitride ALBN: boron nitride + aluminum nitride + aluminum boron oxide.

5、Zirconia boron nitride ZRBN: boron nitride + zirconia + boron oxide.

6、Zirconium aluminum boron nitride ZABN: boron nitride + zirconia + aluminum nitride + boron aluminum oxide.

7、Silicon carbide boron nitride SCBN: boron nitride + silicon carbide + boron oxide.

Pyrolytic boron nitride (Pyrolytic Boron Nitride,PBN) is a new type of ceramic material prepared by chemical vapor deposition (CVD). Its structural characteristics are very similar to those of graphite. With excellent dielectric and insulation properties, sealing properties, high temperature strength, high chemical properties and anisotropic thermal conductivity, not only PBN plates can be prepared, but also crucibles, boats, coatings and other PBN final products can be prepared directly.

1、 Main features

(1) non-toxic and tasteless.

(2) High purity.

(3) it does not react with acids, bases, salts and organic reagents at room temperature, and slightly corrodes in molten salt and lye, but it can resist the corrosion of various acids at high temperature.

(4) do not react with most molten metals, semiconductors and their compounds.

(5) the oxidation resistance is good when the temperature is below 1000 ℃.

(6) the thermal shock resistance is good, and there is no crack in the water at 2000 ℃.

(7) High operating temperature, no sublimation point, directly decomposed into B and N above 3000 ℃.

(8) High resistance and good electrical insulation.

(9) the surface is smooth, without pores and non-wetting with most semiconductor melts.

2、 Product application

(1) OLED evaporation unit.

(2) semiconductor single crystal growth (VGF, LEC) crucibles.

(3) MBE evaporation crucible.

(4) MOCVD heater.

(5) Polycrystalline synthetic boat.

(6) PBN infrared window.

(7) Microwave tube for satellite communication.

(8) PBN coated carrier plate.

(9) Insulation board for high temperature and high vacuum equipment.

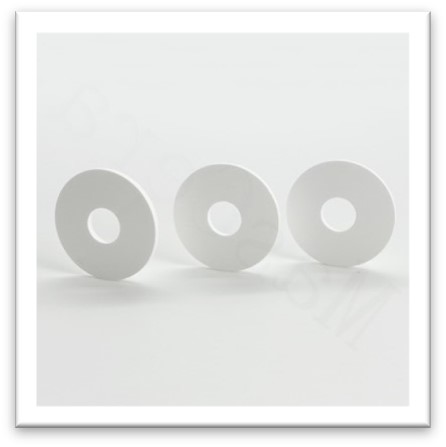

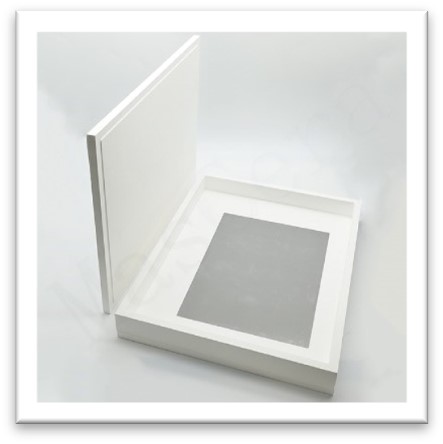

Pbn Pyrolytic Boron Nitride Crucible Pbn Pyrolytic Boron Nitride Ceramic Washer

Hot pressed boron nitride (BN)is a boron nitride ceramic prepared by high temperature sintering processes such as pressureless sintering, hot pressing sintering and hot isostatic pressing sintering. It has the advantages of excellent high temperature resistance, corrosion resistance to molten metal and slag, high thermal conductivity, high electrical insulation, easy processing, high processing precision (up to 0.01mm), lubrication and so on.

1、 Main features

(1) High heat resistance: oxidation begins in oxidation atmosphere at 900C, can be used safely in vacuum at 2000 ℃, is not soft in inert gas at 2800 ℃, and its strength at 1800 ℃ is twice as strong as that at room temperature.

(2) High thermal conductivity: the hot-pressed product is 33w/mk, which has better thermal conductivity among ceramic materials above 530C.

(3) low coefficient of thermal expansion: the coefficient of thermal expansion of 210-6 is second only to that of timely glass and is smaller than that of ceramics.

(4) good insulation performance at high temperature.

(5) good corrosion resistance.

(6) the low friction coefficient is 0.16 and does not increase at high temperature.

(7) the machinable Morse hardness is 2, so it can be machined into high-precision parts with a machining accuracy of 0.01mm.

According to the above characteristics, hot-pressed boron nitride can be used to melt evaporating metal crucibles, boat vessels, liquid metal delivery pipes, crucibles for synthesizing GaAs crystals, rocket nozzles, high-power device bases, molten metal pipes, pump parts, steel casting moulds, etc.

2、 Hot-pressed boron nitride products

From left to right, they are:

Hexagonal Hot Pressed Boron Nitride Crucibles

Boron Nitride Break Ring For Horizontal Continuous Casting

Hot Pressed Boron Nitride Ceramic Parts

From left to right, they are:

Hot Pressed Boron Nitride Ceramic Rings

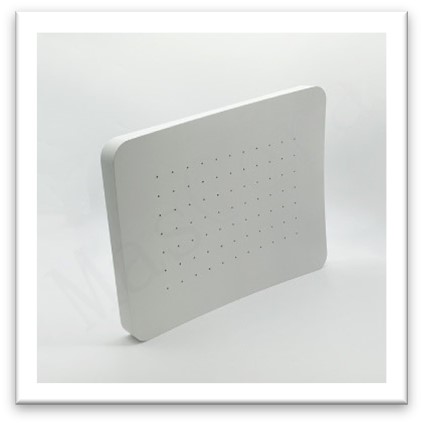

boron nitride plate for precision glass molding

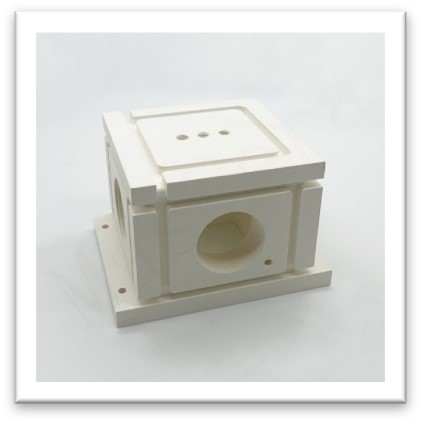

Boron nitride Components for Semiconductor Equipment

From left to right, they are:

Boron nitride square crucible for sintering ceramic substrates

Boron Nitride Ceramic Nozzle For Eiga Process

Boron Nitride Composite Evaporation Boat for Vacuum Deposition Coating

Grade Zsbn Boron Nitride Ceramic Nozzle

Hot Pressed Boron Nitride Ceramic Plate

XIAMEN MASCERA TECHNOLOGY CO., LTD.is one of the leading suppliers of boron nitride products, we can provide you with a wide range of boron nitride product customization services to meet your various needs.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.