Main Processes of Alumina Ceramic Products

According to the Al2O3 content, alumina ceramics are categorized into various types such as 99% alumina, 96% alumina, 95% alumina, 90% alumina, and 85% alumina. Among them, 99% alumina ceramics are used to manufacture high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials. 95% alumina ceramics are mainly used for corrosion-resistant and wear-resistant parts. 85% alumina ceramics, often mixed with talc, have improved electrical properties and mechanical strength, allowing them to be sealed with metals like molybdenum, niobium, and tantalum, and used in some electrical vacuum devices. So, what are the main processes of alumina ceramic products? They mainly include the following four steps:

1、Powder Preparation

Alumina powder is prepared according to different product requirements and forming processes. The particle size of the powder should be below 1 μm. For high-purity alumina ceramic products, in addition to the purity of 99.99% alumina, ultra-fine grinding and uniform particle size distribution are required. When extrusion or injection molding is used, a binder and plasticizer, usually a thermoplastic plastic or resin with a weight ratio of 10-30%, should be added to the powder. The organic binder should be uniformly mixed with alumina powder at 150-200°C to facilitate molding operations. If semi-automatic or fully automatic dry pressing is used, the powder needs special processing, such as spray granulation to make it spherical, improving powder flowability for automatic mold filling during forming. Additionally, 1-2% of a lubricant (e.g., stearic acid) and binder PVA are added to reduce friction between the powder and mold walls.

2、Molding and Pressing

The molding methods for alumina ceramics include dry pressing, slip casting, tape casting, etc. Different shapes, sizes, complex forms, and precision products require different molding methods. Below are introductions to common molding methods:

● Dry Pressing

Dry pressing is a relatively mature process that uses external force to increase internal friction, causing particles to bond and maintain a certain shape.

The advantages are simplicity, ease of operation, and suitability for automated production. However, it faces challenges in producing large blanks, mold wear, complexity, high cost, and uneven pressure distribution leading to density and shrinkage inconsistencies, causing cracking and delamination.

● Slip Casting

The key to slip casting is preparing alumina slurry, usually with water as the medium, adding a deflocculant and binder, thoroughly grinding, degassing, and pouring into plaster molds. After demolding, drying, and binder removal, the product is sintered.

Slip casting is simple, produces uniform green bodies with high strength, and is suitable for large, complex ceramic parts. The downsides are long production times and high mold consumption.

● Tape Casting

Also known as the doctor blade method, this novel technique is suitable for thin ceramic sheets. The process involves adding binders, dispersants, and plasticizers to ceramic powder to create a uniform slurry that meets the required thickness. However, it produces low-density green bodies with high shrinkage.

3、High-Temperature Sintering

Sintering is a densification process that transforms granular ceramic bodies into solid materials by removing voids between particles, gas, and impurities, allowing particles to grow and bond. Electric furnaces are widely used for sintering, with temperatures ranging from 1000 to 1800°C depending on alumina purity.

4、Post-Processing

Some alumina ceramic materials require further finishing after sintering:

● Grinding and Polishing

Due to the high hardness of alumina ceramics, harder materials like SiC, B4C, or diamonds are used for finishing. A step-by-step grinding process from coarse to fine abrasives is followed by surface polishing.

●Cutting

Cutting processes allow for the segmentation of alumina ceramics into various shapes and sizes as needed.

● Drilling

CNC or laser machines are used to drill holes of different sizes in alumina ceramics.

● Glazing

Glazing involves coating the surface of alumina ceramic products with a layer of glaze, which is then sintered at high temperatures to form a smooth, wear-resistant surface.

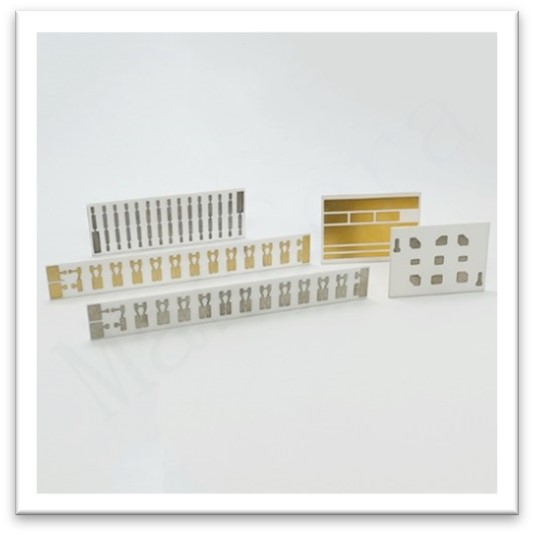

● Metallization

Metallization involves firmly adhering a metal film to the surface of alumina ceramics, enabling ceramic-to-metal bonding.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.