Introduction to Macor Ceramics

Macor ceramic, fully known as "Machinable Ceramic," is a type of machinable glass ceramic. This unique engineering material is widely used in aerospace, semiconductor, laboratory equipment, and other high-tech fields due to its excellent machinability, thermal stability, and electrical insulation properties. Macor ceramic differs significantly from ordinary ceramics in terms of composition, structure, and performance. This article will provide a detailed introduction to the characteristics of Macor ceramic and its differences from ordinary ceramics.

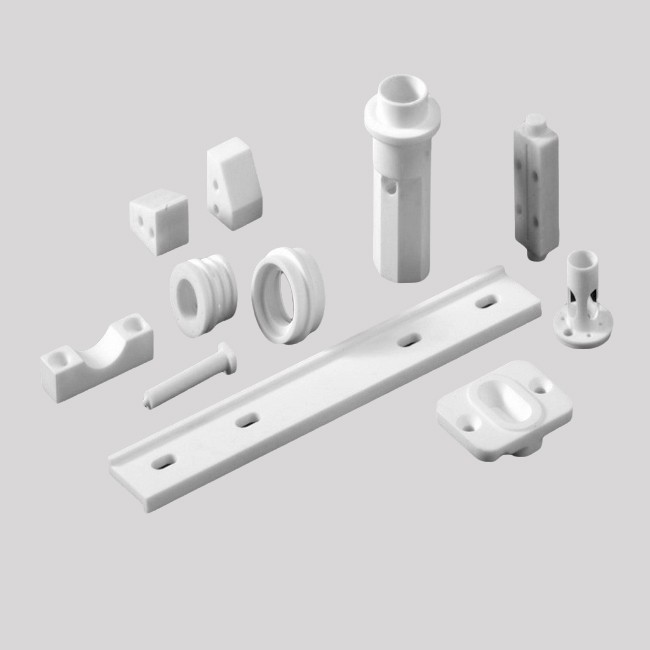

Machinable Glass Ceramics Offered by Mascera: Machinable Glass Ceramic Sheet,

Machinable Glass Ceramic Rod, etc.

1、Characteristics of Macor Ceramics

Machinability

The most notable feature of Macor ceramics is their machinability. It can be processed using standard metalworking tools for drilling, turning, grinding, sawing, polishing, and milling without the need for special equipment or techniques. This machinability provides great flexibility in manufacturing complex shapes and precise dimensions.

Zero Porosity

Macor ceramics exhibit zero porosity, meaning their microstructure has virtually no pores. This zero porosity endows Macor ceramics with excellent chemical corrosion resistance and electrical insulation while also enhancing their mechanical strength and thermal stability.

Thermal Stability

Macor ceramics possess exceptional thermal stability, maintaining structural integrity at temperatures up to 1000°C. Their thermal expansion coefficient is similar to that of many metals, allowing Macor ceramics to be directly bonded with metals without generating thermal stress.

Electrical Insulation

Macor ceramics are excellent electrical insulators, with a volume resistivity of 10^14 to 10^15 ohm·cm, capable of maintaining good electrical insulation properties even in high-temperature and humid environments.

Chemical Stability

Macor ceramics have good chemical stability, resisting corrosion from almost all chemicals except hydrofluoric acid and molten alkali metals. This includes resistance to organic solvents, acids, bases, and salt solutions.

2、Differences Between Macor Ceramics and Ordinary Ceramics

Composition Differences

The main components of Macor ceramics are silica, alumina, beryllium oxide, and boron oxide, whereas ordinary ceramics are typically composed mainly of alumina, zirconia, silicon carbide, etc. This difference in composition results in significant performance differences between Macor ceramics and ordinary ceramics.

Structural Differences

Macor ceramics have a microstructure with virtually no pores, while ordinary ceramics often contain a certain amount of porosity. This structural difference gives Macor ceramics superior chemical corrosion resistance, electrical insulation, and mechanical strength compared to ordinary ceramics.

Machining Performance

The machinability of Macor ceramics far exceeds that of ordinary ceramics. Ordinary ceramics usually require molding and sintering during the manufacturing process, whereas Macor ceramics can be machined after sintering, greatly enhancing manufacturing flexibility and precision.

Application Fields

Due to its unique properties, Macor ceramics are widely used in fields requiring high precision and complex-shaped components, such as aerospace, semiconductors, and laboratory equipment. Ordinary ceramics, on the other hand, are more commonly used in applications requiring wear resistance, high-temperature tolerance, and electrical insulation.

3、Application Examples of Macor Ceramics

Macor ceramics are used in the aerospace industry to manufacture turbine engine components, heat exchangers, insulation materials, and precision instrument parts. In semiconductor manufacturing, Macor ceramics are used to produce heaters and coolers in wafer processing equipment. In laboratory equipment, Macor ceramics are used in the production of reactors, distillation apparatus, and other devices that require chemical corrosion resistance and high-temperature stability.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, boron nitride , aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.