Introduction to Sintering Techniques of Advanced Ceramic

Advanced ceramic materials, due to their fine structural composition and a series of excellent properties such as high strength, high hardness, high temperature resistance, corrosion resistance, and wear resistance, are widely used in various fields, including aerospace, electronics, machinery, and biomedical. The development of ceramic sintering technology directly influences the progress of advanced ceramic materials and is an essential key step in ceramic product manufacturing.

After initial drying, the green bodies need to undergo sintering to enhance their strength, thermal stability, and chemical stability. During the sintering process, ceramics undergo a series of physical and chemical changes, including volume shrinkage, density increase, improved strength and hardness, and phase transformations in the grains, achieving the required physical and mechanical properties. Different sintering techniques applied to ceramic green bodies with the same chemical composition can result in significant differences in microstructure and performance of the final ceramic materials.

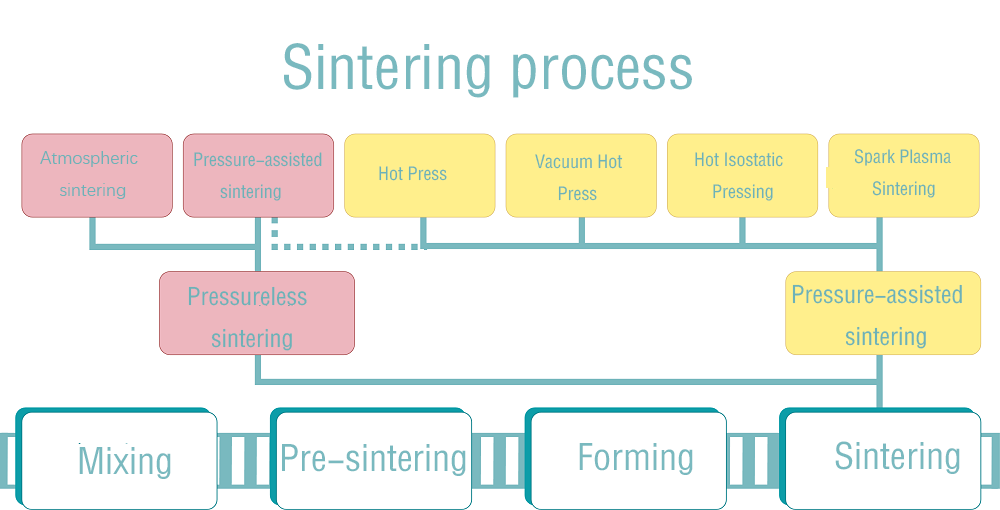

Based on the research target, sintering can be categorized into solid-state sintering and liquid-phase sintering. Depending on the specific processes, sintering methods include pressureless sintering, hot pressing, hot isostatic pressing, atmosphere sintering, microwave sintering, spark plasma sintering, and others. Let's introduce several commonly used sintering techniques:

1.Pressureless Sintering

Also known as atmospheric sintering, this process is conducted without an external driving force. The main driving force for sintering comes from changes in the ceramic powder's surface free energy, resulting in a reduction of the total powder surface area and a decrease in interfacial energy. Pressureless sintering is the simplest and most commonly used sintering process for ceramic materials. For compounds with strong covalent bonding, such as nitrides, carbides, and borides, dense products cannot be obtained solely through solid-state sintering due to their small self-diffusion coefficients. To achieve densification, a small amount of sintering aids is often added to lower the sintering temperature and reduce the grain boundary energy of the solid-state diffusion process, promoting densification.

Materials sintered through pressureless sintering may exhibit slightly lower performance compared to those sintered through hot pressing, hot isostatic pressing, and atmosphere sintering. However, the process is simple, does not require special equipment, is cost-effective, and allows for the preparation of complex-shaped products and batch production.

2.Gas Pressure Sintering

Gas pressure sintering was developed simultaneously in Japan and the United States. It involves sintering ceramic products under high temperature and pressure conditions using pressurized nitrogen or other inert atmospheres. Gas pressure sintering meets the needs for sintering certain special ceramic materials, such as preventing decomposition. During the later stages of the holding period, the applied pressure helps achieve an isotropic pressing process similar to hot isostatic pressing, which further improves the material's properties.

3.Hot-pressing

Hot-pressing (HP) is a sintering method that involves mechanical pressure. In this process, ceramic powder is placed into a mold cavity and heated to the sintering temperature while being subjected to pressure. The external pressure supplements the driving force, allowing for densification to occur in a relatively short time and resulting in a microstructure with fine and uniform grains. This sintering technique provides improved mechanical properties, reduces sintering time, or lowers the sintering temperature, which in turn decreases the amount of covalent ceramic sintering aids and ultimately enhances the material's high-temperature mechanical performance.

4.Hot Isostatic Pressing

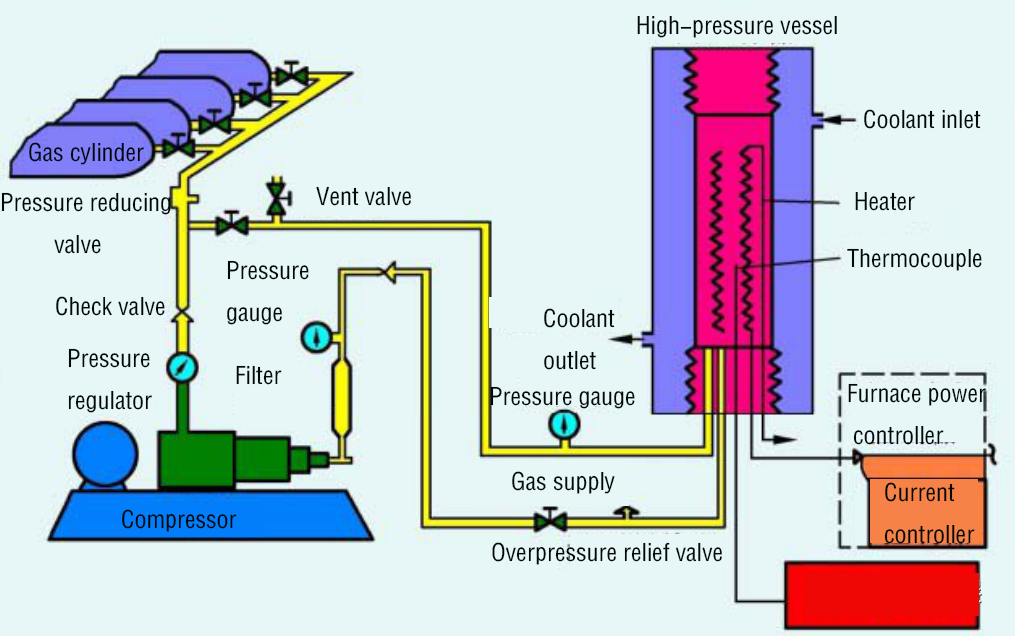

Hot Isostatic Pressing (HIP) technology was initiated in 1955 by the Battelle Columbus Laboratory in the United States for the development of materials for nuclear reactors. The introduction of the first HIP machine by the Battelle Columbus Laboratory in 1965 marked the birth of hot isostatic pressing equipment.

Hot isostatic pressing is a sintering technique that utilizes inert gases such as nitrogen or argon as pressure-transmitting media. The process involves placing the product in a sealed container and subjecting it to equal pressures from all directions under a combination of temperatures ranging from 900°C to 2000°C and pressures of 100~200 MPa, thereby achieving a simultaneous pressurized sintering treatment. Hot isostatic pressing can be classified into two types: (1) sintering after encapsulating or directly encapsulated ceramic powder with subsequent high-temperature isostatic pressing, and (2) post-processing through high-temperature isostatic pressing after ceramic powder shaping and sintering.

This sintering method results in products with high density, excellent uniformity, and outstanding performance. Additionally, the technique offers advantages such as short production cycles, reduced process steps, low energy consumption, and minimal material loss.

5.Spark Plasma Sintering (SPS)

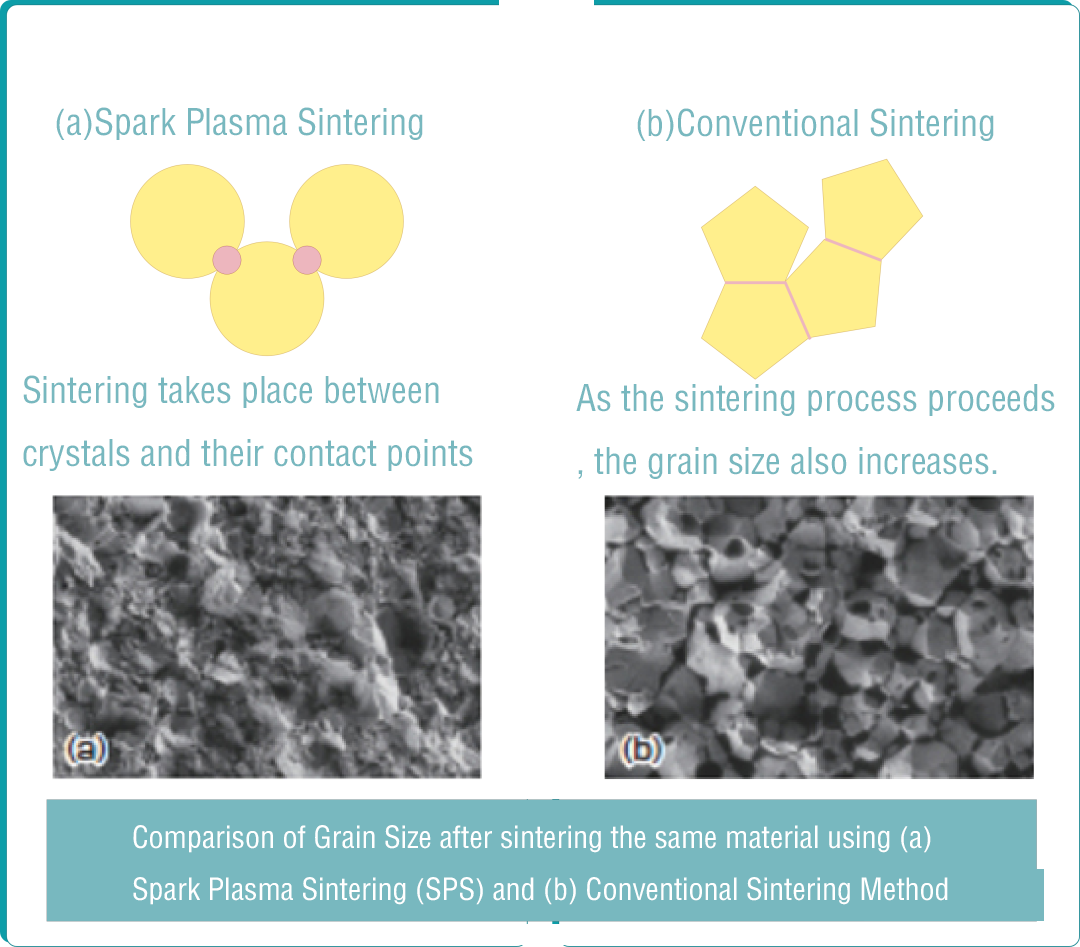

Spark Plasma Sintering (SPS) is a new rapid sintering technique developed in Japan in recent years. It utilizes pulsed electrical current for pressure-assisted sintering. The pulse current causes the processed material to self-heat, and the energy of the discharge plasma between particles achieves rapid and dense sintering. The sintering mechanism of SPS is generally believed to involve the Joule heating of conventional hot pressing and the plastic deformation caused by pressure. Additionally, direct current pulse voltage occurs between powder particles, utilizing the spontaneous heating effect of powder particle discharge, resulting in some unique phenomena specific to the SPS process.

Compared to traditional sintering techniques, SPS offers advantages such as rapid heating, short heating time, and low sintering temperature, allowing for the formation of materials with ultrafine or even nanoscale grains and exhibiting no significant anisotropy.

6.Microwave Sintering

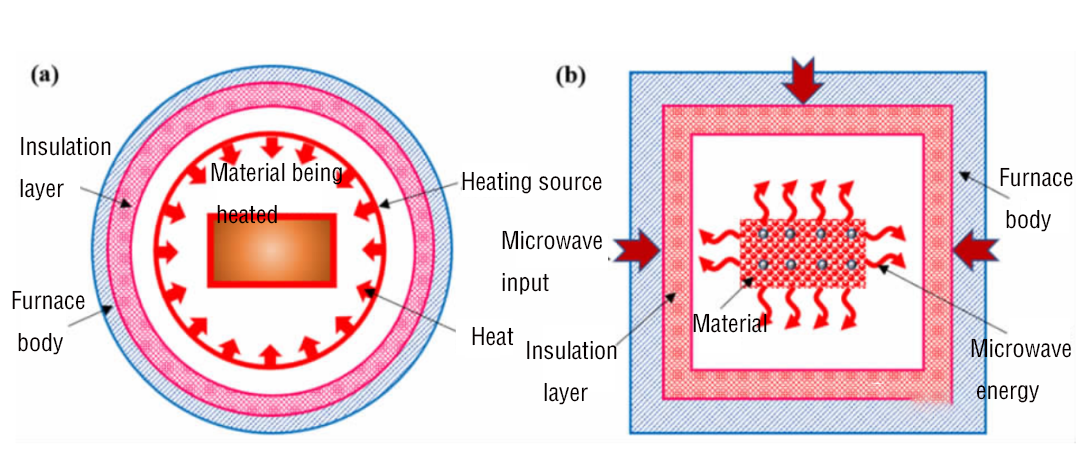

Microwave sintering of ceramic materials was first proposed by Levinson and Tinga in the mid-1960s. It utilizes the dielectric loss of ceramic materials in microwave electromagnetic fields to achieve sintering and densification. During microwave sintering, materials absorb microwave energy, converting it into molecular kinetic and potential energy within the material. This results in uniform heating, minimal internal temperature gradients, and fast heating and sintering rates. Microwave sintering can achieve low-temperature rapid sintering, significantly improving the mechanical properties of ceramic materials. Moreover, it does not require a heat source, making it highly efficient and energy-saving. It boasts high production efficiency, low unit cost, and holds promising prospects for the preparation of ceramics at the sub-millimeter or even micrometer scale, offering a new route for ceramic material synthesis.

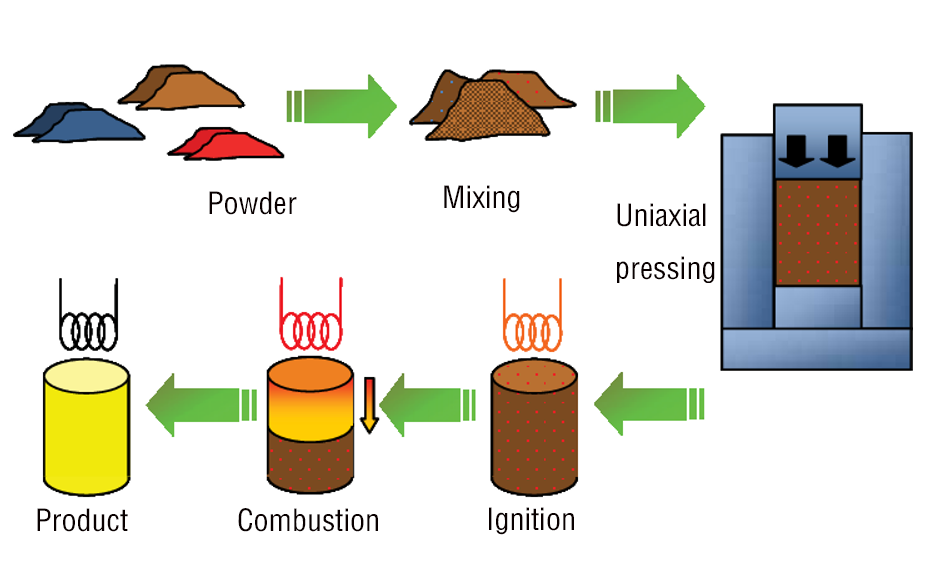

7.Self-propagating high-temperature synthesis

Self-propagating high-temperature synthesis (SHS) is a material preparation technique that emerged in the mid-20th century, proposed by the former Soviet scientist Merzhanov. This method is based on the principle of exothermic chemical reactions, utilizing external energy to induce localized chemical reactions, resulting in the formation of a chemical reaction front (combustion wave). Subsequently, the chemical reaction continues with the support of the heat released by itself, and as the combustion wave propagates, the combustion spreads throughout the entire system, synthesizing the desired materials. SHS sintering refers to the use of the high heat released by SHS reactions, combined with hot pressing or hot isostatic pressing, to achieve simultaneous synthesis and densification, ultimately reaching material densities close to or equal to theoretical densities.

This method is characterized by simple equipment and processes, rapid reactions, high product purity, and low energy consumption. It is suitable for synthesizing compounds with non-stoichiometric chemical ratios, intermediate products, and metastable phases, among others. Since the 1980s, self-propagating high-temperature synthesis technology has undergone rapid development and has been successfully applied to industrial production. It has been integrated with various other technologies in related fields, resulting in a series of related techniques, such as SHS powder synthesis, SHS sintering, SHS densification, SHS metallurgy, and more. Self-propagating high-temperature synthesis can be utilized not only in ceramic powder synthesis and ceramic materials sintering but also in the preparation of high-melting-point materials rods, single crystal pulling, and surface treatment of metals for nitriding or carburizing.

The future of sintering technology is moving towards precision, controllability, and energy efficiency. New sintering techniques have become a hot topic in current research on ceramic material sintering due to their potential for energy and time-saving benefits.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.