The main application of alumina ceramics

The main application of alumina ceramics

1. Electronics and electricity

In terms of electronics and electricity, there are various alumina ceramic bottom plates, substrates, ceramic films, transparent ceramics, and various alumina ceramic electrical insulating ceramic parts, electronic materials, magnetic materials, etc. Among them, alumina transparent ceramics and substrates are used the widest.

2. Chemical industry

In chemical applications, alumina ceramics also have a wide range of uses, such as alumina ceramic chemical filler balls, inorganic microfiltration membranes, corrosion-resistant coatings, etc. Among them, alumina ceramic membranes and coatings are the most studied and applied.

①Alumina ceramic membrane: Membranes are divided into organic polymer membranes and inorganic membranes. Since the 1980s, the research and development of alumina ceramic membranes, especially porous alumina ceramic membranes, has been greatly improved. occupies an important position. Alumina ceramic membranes have a large number of applications in purification of industrial water, seawater desalination, gas separation, catalytic reactions, etc. Therefore, ceramic inorganic membranes have increasingly attracted widespread attention from the scientific and technological and industrial circles.

②Alumina coating: Titanium alloy material is seriously oxidized at high temperature. In order to improve its performance, an alumina coating can be applied to the surface of the titanium alloy material, which can also improve the corrosion resistance and high temperature oxidation resistance of the titanium alloy material.

3. Medical aspects

In medicine, alumina is more used to make artificial bones, artificial joints, artificial teeth, etc. Alumina ceramics have excellent biocompatibility, biological inertness, physical and chemical stability, high hardness and high wear resistance, and are ideal materials for the preparation of artificial bones and artificial joints. However, it has the same shortcomings as other ceramic materials, such as high brittleness, low fracture toughness, high technical difficulty in machining, and complicated process, so further research and application are required.

4. Building sanitary ceramics

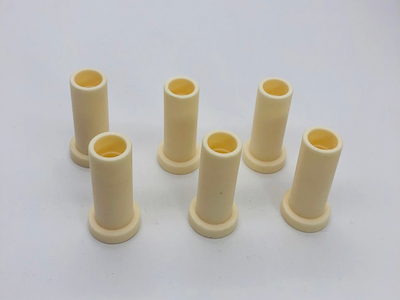

In building sanitary ceramics, alumina ceramic products can be seen everywhere, such as alumina ceramic lining bricks, grinding media, sticks, ceramic protection tubes and alumina refractory materials. Among them, alumina ball milling media is the most widely used. Alumina ball milling media has the characteristics of suitable hardness, moderate density, wear resistance, corrosion resistance and low price, so most of the raw materials for building sanitary ceramics are processed with alumina ball milling media.

5. Other aspects

Alumina ceramics is one of the most studied and widely used materials among new materials. In addition to the above applications, it is also widely used in other high-tech fields, such as aerospace, high-temperature industrial furnaces, composite reinforcement and other fields. .

① Aerospace

Alumina-based fibers are widely used in aerospace, which have various properties such as high strength, high temperature resistance, oxidation resistance, and corrosion resistance. Alumina can be prepared into high-temperature and heat-resistant fibers, which are used in thermal insulation tiles and flexible thermal insulation materials on space shuttles. Not only that, the use of alumina fibers can also be used to strengthen metal-based and ceramic-based composite materials, which are widely used in nozzles in supersonic jets and gaskets in rocket engines.