Advantages and Disadvantages of AlN Ceramic

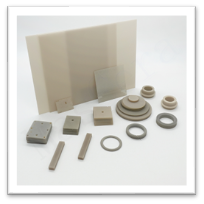

Aluminum nitride ceramic (AlN ceramic) is a solid compound composed of aluminum and nitrogen. It possesses unique properties that make it highly valuable in various high-tech applications, especially in optoelectronics, semiconductors, and electronic packaging.

optoelectronics, semiconductors, and electronic packaging.

Advantages of AlN Ceramic

1.High Thermal Conductivity AlN

Among technical ceramics, aluminum nitride ceramic exhibits one of the highest thermal conductivities, typically ranging between 100 W/(m·K) and 200 W/(m·K). This value is 10 to 15 times higher than alumina (Al₂O₃) at room temperature. Due to its superior heat dissipation capability, AlN ceramic is widely used in semiconductor substrates and electronic packaging, ensuring efficient thermal management in microelectronic applications.

2.High Volume Resistivity

The aluminum and nitrogen atoms in AlN ceramic form a strong covalent bond, resulting in a stable crystal structure. This structural stability restricts the free movement of electrons, leading to a high volume resistivity, typically around 10¹⁴ Ω·cm. Due to its excellent electrical insulation, aluminum nitride ceramic is an ideal material for electronic and power applications, offering superior dielectric performance.

Compared to other common insulating materials such as quartz and traditional ceramics, aluminum nitride ceramic has a significantly higher dielectric breakdown strength. This is attributed to its wide bandgap and high breakdown field strength, making it an excellent material for high-voltage and high-frequency electronic devices.

4.Low Thermal Expansion Coefficient

AlN ceramic has a low thermal expansion coefficient of approximately 4.6 × 10⁻⁶/°C, ensuring excellent dimensional stability. Moreover, its thermal expansion coefficient closely matches that of silicon, making it an ideal choice for precision-controlled environments, including semiconductors, optical devices, and high-temperature applications.

Disadvantages of AlN Ceramic

1.Hydrolysis Sensitivity

One of the main disadvantages of AlN ceramic is its tendency to undergo hydrolysis when exposed to water. The Al-N bonds in aluminum nitride are relatively weak and can be attacked by water molecules, leading to the formation of aluminum hydroxide and ammonia gas. This reaction compromises the stability of AlN ceramics in humid environments, potentially affecting electronic system reliability.

2.Brittleness

Despite its excellent thermal and electrical properties, aluminum nitride ceramic has low fracture toughness, making it susceptible to chipping and cracking under impact or mechanical stress.

3.High Cost

The high cost of aluminum nitride ceramic is another significant limitation. The raw material price remains high, and its machining is complex and time-consuming due to the material’s high hardness and wear resistance. These factors contribute to increased production costs, restricting the widespread application of AlN ceramic.