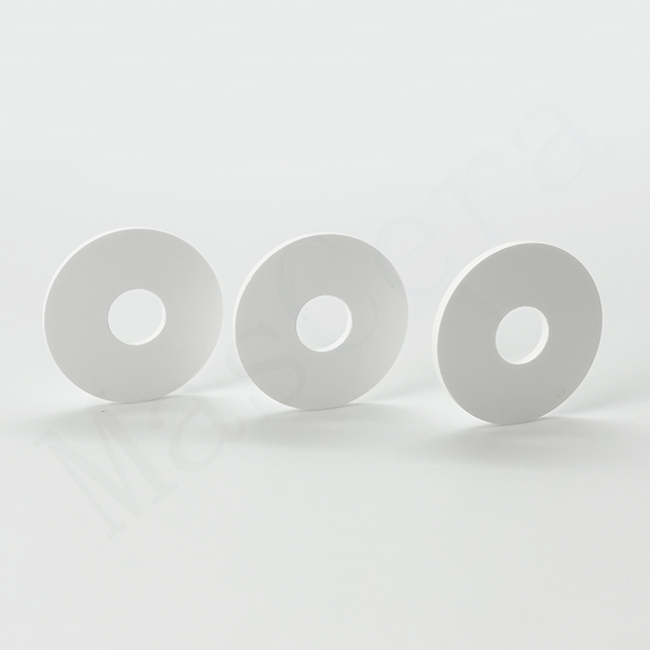

Pbn Pyrolytic Boron Nitride Boat for semiconductor manufacturing

- MSJ/BN-015

- Pyrolytic Boron Nitride (PBN)

- Customized

- 10 pcs per type

- Industrial Applications

PBN boats are manufactured using the Chemical Vapor Deposition (CVD) process, featuring exceptional purity, outstanding thermal stability, and excellent electrical insulation. PBN boats characteristics make them ideal for semiconductor manufacturing, precision crystal growth, and other high-temperature processes.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

Pyrolytic Boron Nitride (PBN) boats are advanced ceramic vessels manufactured through a specialized chemical vapor deposition (CVD) process. In this process, boron trichloride (BCl₃) and ammonia (NH₃) react at high temperatures and low pressures to synthesize high-purity boron nitride. This meticulous manufacturing technique enables PBN boats to achieve an exceptional purity level of 99.999%. Such stringent production methods lay the foundation for the outstanding performance characteristics of PBN boats.

PBN boats are renowned for their exceptional thermal conductivity and high-temperature stability, capable of withstanding extreme conditions in inert atmospheres. Their chemically inert nature ensures that they do not react with most acids, alkalis, or molten metals, making them ideal for use in high-purity environments. Additionally, PBN boats exhibit excellent electrical insulation properties and low outgassing, which minimizes contamination during sensitive processes, thereby ensuring the integrity and purity of the materials being processed.

At Mascera, we are committed to delivering the highest quality PBN boats. All PBN boats are manufactured under strict quality control systems to ensure optimal purity and consistency for high-performance applications. Each batch undergoes rigorous testing for purity, density, and mechanical properties, ensuring that our products meet the highest standards of excellence. Through these stringent quality controls, Mascera guarantees that every PBN boat is designed to perform reliably in demanding applications.

Product Features

1. High Purity(>99.99%)

2. High Dielectric Strength and exceptional resistivity

3. Outstanding Thermal Stability

4. Excellent Anisotropic Thermal Conductivity

5. High Interlayer Strength

6. Chemically Inert and Corrosion Resistant

Product Applications

Semiconductor Manufacturing

PBN Boats are widely used in the production of semiconductors for processes like chemical vapor deposition (CVD) and epitaxy. Their high purity and non-wetting properties make them ideal vessels for precise material deposition.

Crystal Growth

PBN Boats serve as essential vessels for crystal growth processes, providing a clean and inert environment. They are commonly employed in research and industrial settings for growing crystals with high purity.

Metal Organic Chemical Vapor Deposition (MOCVD)

In MOCVD processes for thin-film deposition, PBN Boats play a critical role. Their non-wetting characteristics with melted metals ensure precise and contamination-free material deposition.

High-Temperature Furnace Applications

PBN Boats are utilized as containers in high-temperature furnaces for processes requiring extreme thermal stability and resistance. They contribute to maintaining a controlled environment for various heat treatment applications.

Research and Development

PBN Boats are extensively used in research and development laboratories for various synthesis and experimentation processes. Their reusability, combined with high thermal shock resistance, makes them valuable in diverse scientific applications.

Material Data Sheet

| Property | Unit | Technical Value |

|---|---|---|

| Density | g/cm3 | 1.95-2.22 |

| Lattice constant | m | a:2.5x10-10 c:6.8x10-10 |

| Tensile strength | Mpa | 80 |

| Bending strength | Mpa | 243 |

Thermal conductivity (at 200℃) | w/mk | 82.3(a) 2.6(c) |

Thermal conductivity (at 900℃) | w/mk | 55.3(a) 2.8(c) |

| Thermal expansion coefficient | mm/mm/k | 2.0x10-6(a) |

| Dielectric Constant (10GHz) | - | 5.2(a) 3.8(c) |

| Dielectric Strength | Kv/mm | 56 |

| Electrical Resistivity | Ω.cm | 1015 |

| Total Metallic Impurities | ppm | ≤10 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |