Silicon Nitride Si3N4 Ceramic Dgassingrotor Shaft For Aluminum Processing Industry

- MSJ/SN-013

- Silicon Nitride Ceramic

- Customized

- 5 pieces per type

- Aluminum Processing Industry

Silicon nitride (Si3N4) ceramic dgassingrotor shafts offer superior wear resistance and oxidation resistance compared to graphite rotors. These properties ensure their efficient and stable hydrogen removal performance over prolonged usage, significantly reducing the frequency of part replacement and lowering costs.

For inquiries, please email info@mascera-tec.com or call +86 13860446139

Product Details

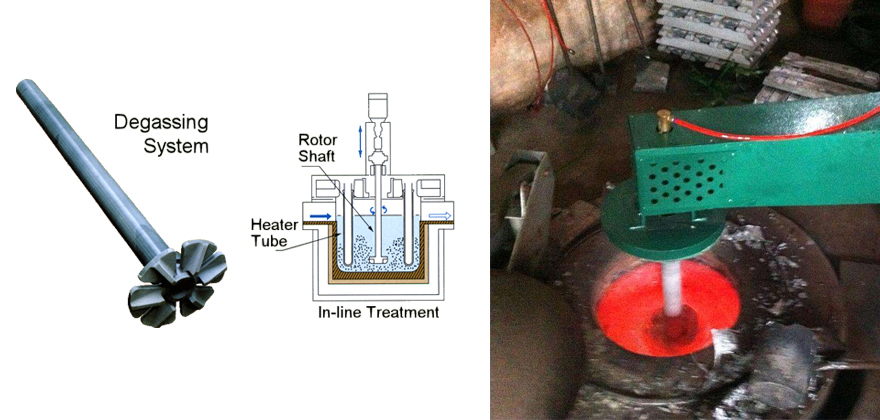

The working principle of the degassing rotor is that the rotating rotor breaks the nitrogen (or argon) gas blown into the aluminum melt into numerous dispersed bubbles and distributes them throughout the liquid metal. These bubbles absorb hydrogen from the melt and adsorb oxides and inclusions. As the bubbles grow, they rise to the surface of the melt and are expelled, thus purifying the melt and effectively removing harmful hydrogen from the aluminum melt.

Compared to graphite rotors, silicon nitride (Si3N4) ceramic degassing rotor shafts exhibit excellent wear resistance and oxidation resistance. These properties ensure efficient and stable hydrogen removal during prolonged use, significantly reducing the frequency of component replacements and thereby lowering costs.

Mascera offers both standard and customized silicon nitride ceramic degassing rotor shafts to meet various customer requirements. The structural design of the rotor impeller promotes uniform gas distribution within the molten aluminum, minimizes turbulence caused by the gas, and prevents vortex formation. This superior gas dispersion capability significantly enhances hydrogen removal efficiency, improving the quality of castings. hydrogen removal efficiency, improving the quality of die cast components.

Material Data Sheet

| Item | Unit | Technical parameters |

Density | g/cm³ | 3.2-3.4 |

Porosity | % | <0.5 |

Vickers Hardness | Mpa | 15 |

Fracture Toughness | Mpa.M1/2 | 8.04 |

Bending Strength | Mpa | 791 |

Young's Modulus | -- | 290 |

Thermal Conductivity | W/Mk | 29.9 |

Thermal Expansion Coefficient | 10-6/℃ | 3.2 |

Max Operation Temperature | ℃ | 1200 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |