Boron Nitride (BN)

Boron Nitride, is an advanced ceramic material synthesized from hexagonal boron nitride. Known as "white graphite" . Boron nitride resembles graphite, but unlike graphite, it acts as an excellent electrical insulator with a higher oxidation temperature. It exhibits remarkable thermal conductivity, thermal shock resistance, and can be easily machined into precise shapes.

a higher oxidation temperature. It exhibits remarkable thermal conductivity, thermal shock resistance, and can be easily machined into precise shapes.

The performance and suitability of Boron Nitride materials are influenced by variations in their composition, including the type and amount of binder, overall composition, and the bonding between layers. These factors play a crucial role in determining the unique characteristics exhibited by different Boron Nitride products. With the backing of industry-leading international technical support from MASCERA offers a comprehensive range of solutions, including machinable blanks and customized finished shapes.

Properties

+Excellent thermal shock resistance | +High thermal conductivity |

| +High electrical resistivity | +Non-wetting with molten metals |

| +High corrosion resistance | +Very high working temperature |

| +High dielectric breakdown strength | +Excellent Machinability |

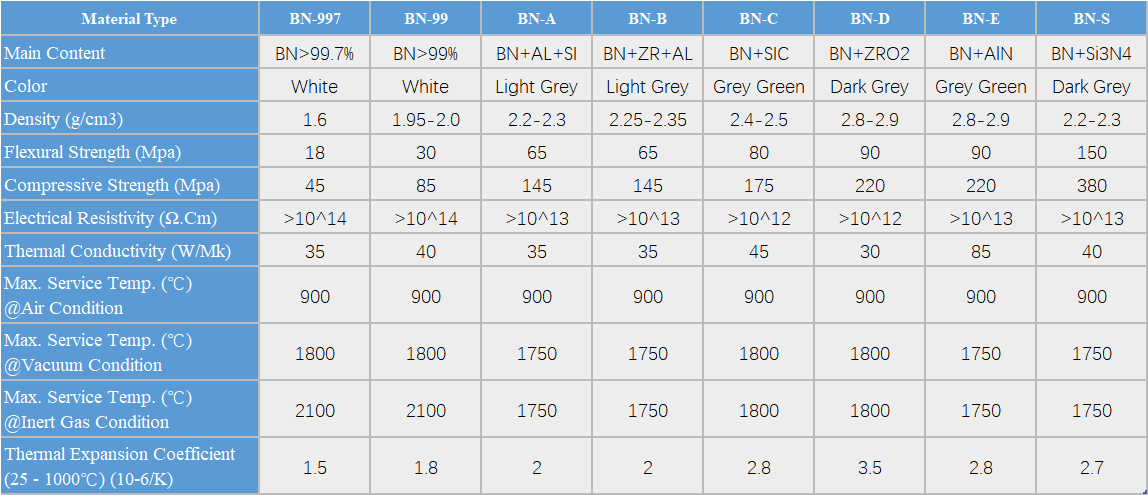

Material Grades

HPBN-BN-99

BN-99 is a ceramic material made from high-purity boron nitride. It is white in color, with excellent electrical insulation, high-temperature resistance, and chemical inertness, along with good thermal conductivity and high thermal shock resistance. It is widely used in semiconductor, metal smelting, and aerospace fields. Common applications include insulation sleeves for electrodes in vacuum sintering furnaces and atmosphere furnaces, thermocouple protection sleeves, insulating components in vacuum coating equipment, insulating components in polycrystalline silicon ingot furnaces, and molds for shaping metal or glass.

HPBN-BN-997

BN-997 is made of 99.7% boron nitride, white and offering outstanding thermal conductivity and high-temperature performance, making it widely used in metal processing. Due to its high purity, it does not bond or contaminate products and withstands repeated high- and low-temperature impacts and corrosion, thus extending its service life. It is suitable for sintering and melting alloys, aluminum nitride substrates, silicon nitride substrates, transparent ceramics, aluminum nitride powders, and rare earth materials.

HPBN-BN-A

BN-A is a boron nitride material compounded with aluminum and silicon, light grey. It has excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. Due to its Al and Si composition, it has significantly enhanced mechanical strength compared to high-purity boron nitride, making it more suitable for powder metallurgy applications, such as high-temperature furnace components, molten metal transport tubes, and nozzles.

HPBN-BN-B

BN-B is a boron nitride material compounded with aluminum and zirconium, light grey. It possesses excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. With the addition of Al and Zr, it has enhanced mechanical strength compared to high-purity boron nitride, making it more suitable for powder metallurgy applications, including high-temperature furnace components, various devices for molten metals or glass, molten metal transport tubes, and nozzles.

HPBN-BN-C

BN-C is a boron nitride material compounded with silicon carbide, with a grey-green color. It offers excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. The addition of SiC significantly increases its mechanical strength compared to high-purity boron nitride, making it ideal for metal casting applications, such as high-temperature furnace components, various devices for molten metal or glass, molten metal transport tubes, and nozzles.

HPBN-BN-D

BN-D is a boron nitride material compounded with zirconium oxide, dark grey. It has excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. The ZrO2 enhances its mechanical strength, especially compressive strength, making it more suitable for metal casting applications, including high-temperature furnace components, various devices for molten metal or glass, high-temperature casting components, molten metal transport tubes, and nozzles.

HPBN-BN-E

BN-E is a boron nitride material compounded with aluminum nitride, with a grey-green color. It has excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. Due to its AlN composition, it has significantly enhanced mechanical strength and higher thermal conductivity than high-purity boron nitride, making it suitable for powder metallurgy applications, including high-temperature furnace components, metal evaporation boats, molds for precious or specialty alloy casting, various devices for molten metal or glass, high-temperature casting components, molten metal transport tubes, and nozzles.

HPBN-BN-S

BN-S is a boron nitride material compounded with silicon nitride, with a dark grey. color. It offers excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. Thanks to its Si3N4 composition, it has the highest compressive strength among all boron nitride composite materials. It is well-suited for non-insulating structural components, particularly as high-temperature supports, components subject to load, molten metal transport, nozzles, and separating rings in horizontal continuous casting.

Data Sheet

Processing

Hot Pressed Sintering(HPBN)

Hot Pressed Boron Nitride (HPBN) is produced through hot-pressing sintering. It offers high density, strength, and cost-effectiveness. HPBN exhibits excellent electrical insulation, lubricity, high-temperature stability, thermal conductivity, dielectric strength, and processability. It finds applications in crucibles, liquid metal conveying pipes, rocket nozzles, high-power device bases, steel casting molds, and insulating materials.

Chemical Vapor Deposition(PBN)

Pyrolytic Boron Nitride (PBN) is synthesized using chemical vapor deposition (CVD) under high temperature and high vacuum conditions. It has high purity, thermal conductivity, mechanical strength, electrical insulation, chemical inertness, and non-toxicity. PBN is used as a container material for element purification and semiconductor crystal growth. Applications include OLED evaporation units, semiconductor single crystal growth crucibles, molecular beam epitaxy (MBE) evaporation crucibles, MOCVD heaters, and high-temperature, high-vacuum equipment insulation boards.

Applications

Thermal Management

Excellent electrical insulation and thermal conductivity make BN very useful as a heat sink in high-power electronic applications. Its properties compare favorably with beryllium oxide, aluminum oxide, and other electronic packaging materials, and are easier machinable to desired shapes and sizes.

High Temperature Environments

Temperature stability and excellent resistance to thermal shock make BN the ideal material in the toughest high-temperature environments such as equipment for plasma arc welding, diffusion source wafers, and semiconductor crystal growth equipment & processing.

Molten Metal Handling

BN is inorganic, inert, nonreactive with halide salts and reagents, and is not wet by most molten metals and slags. These characteristics, combined with low thermal expansion, make it ideal for interface materials used in various molten metal processes.

Related Products