Ceramic Substrates

-

Hot

Electrical Insulation Alumina Ceramic Sheet

Mascera is a professional supplier for technical ceramic parts, we provide custom manufacturing for alumina ceramics, zirconia ceramics, boron nitride ceramics, silicon nitride ceramics, silicon carbide ceramics, aluminum nitride ceramics and machinable glass ceramics.

Email Details

One of our hot selling products is ceramic substrate for electronic package applications. The materials of ceramic substrates we can produce are 96% alumina ceramic and aluminum nitride ceramic. Both have good electrical insulation, good mechanical strength and high heat resistance. Product size could be customized accroding to your request, delivery date could be within 7 days at the fastest.

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Aln Aluminum Nitride Ceramic Substrates

Aluminum nitride substrates are widely applied in large-scale integrated circuits or high power modules because of much higher thermal conductivity than other ceramic materials. Aluminum nitride susbtrates's thermal conductivity is as high as 170 w/mk, which will dissipate heat and cool down the circuits much more quickly. Adding with good insulating properties, aluminum nitride substrates are the best solution in electronics applications where fast heat dissipation is critical. Alumium nitride substrates are heat resistant and have similar expansion coefficient of silicon, which will keep high reliability of Si chip and thermal heat cycling.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

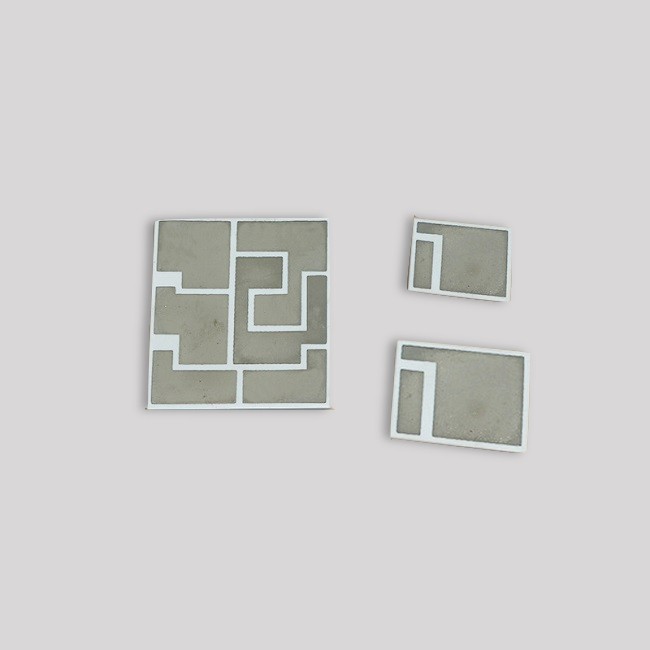

Silicon Nitride Ceramic substrate

MASCERA provides various processing treatments on the surface of the ceramic substrate, such as metallization, polishing, laser scribing, and laser drilling. Additionally, we offer customization services for Nitride Silicon Ceramic Substrates in different sizes. You can provide us with drawings or product size requirements, and we will fulfill your requests accordingly.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

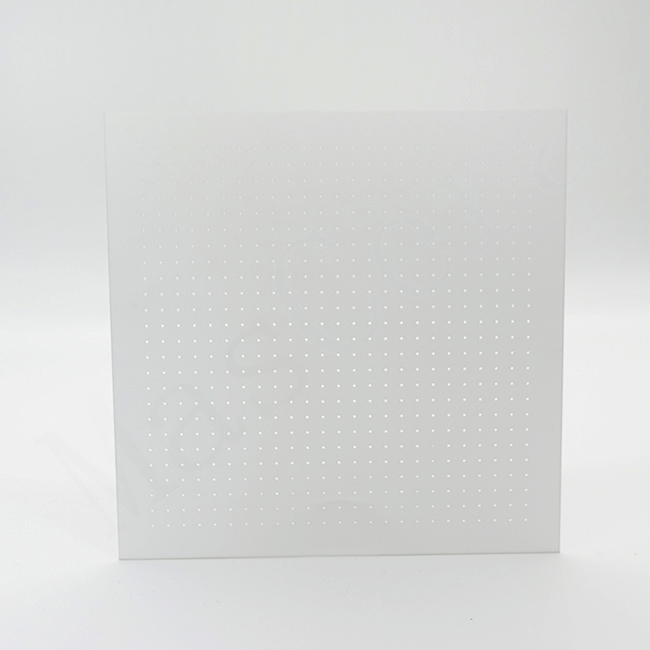

96 Al2O3 Alumina Ceramic Substrates

96% Alumina substrates are the most cost-effective and commonly used ceramic substrate for thick film electronics or power powdules, they are made of electrically insulated 96% alumina (al2o3) ceramic. Alumina substrates have advantages of good electrical insulation, low dielectric properties, good heat resistance and wear resistance. The good thermal conductivity will help electronic modules to dissipate heat efficiently. The shape is stable because of the high strength and good durability, the surface is smooth and flatness is as good as 2‰ of dimensions.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Aln Aluminium Nitride Ceramic Insulation Sheet

Aluminum nitride sheets are made of high thermally conductive aluminum nitride ceramic, the thermal conductivity is up to 170w/mk, is the highest among all our ceramic materials. Except this, aluminum nitride sheets have similar thermal expansion coefficient with silicon, which will matched perfectly with electronic modules when temperature changes. Adding with the good electrical insulation and dielectric properties, aluminum nitride sheets are ideal material for large scale integrated circuits or high power modules.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

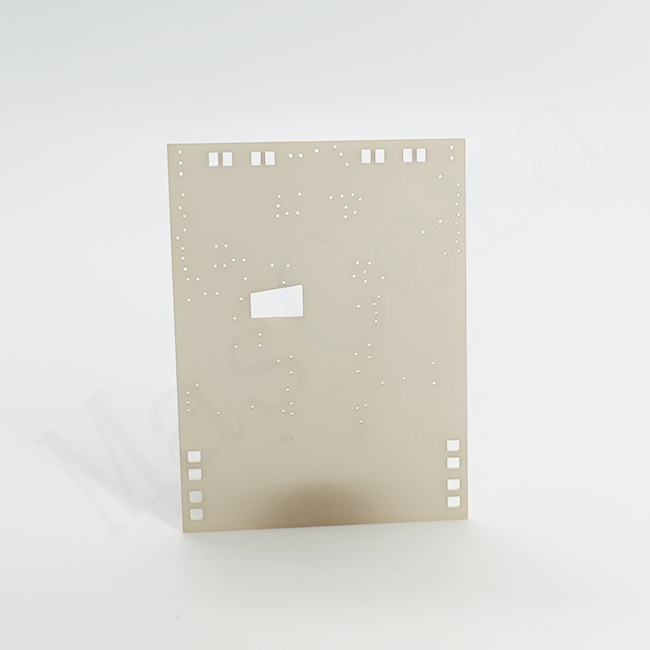

Laser-Drilled Alumina (Al2O3) Ceramic Substrates

The Laser-Drilled 96% Alumina (Al2O3) Ceramic Substrates is a high-performance ceramic material widely used in high-tech industries such as electronics, electrical, and semiconductors. Alumina (Al2O3) substrate offers exceptional mechanical strength, wear resistance, and electrical insulation properties.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Al2O3 Alumina Ceramic Substrate Pcb

Ceramic PCBs have much beter heat dissipation performance, current-carrying capacity, electrical insulation, thermal expansion coefficient than ordinary glass fiber PCB board. Unlike ordinary PCBs, which use adhesives to bond copper foil and substrate together, ceramic PCBs are produced by bonding the copper foil and ceramic substrate directly in a high temperature environment. Ceramic PCBs have strong bonding force, copper foil will not fall off, leading to high reliability and stable performance under high temperature and high humidity environment. Ceramic PCBs are widely used in high-power electronic modules, aerospace, military electronics and other products.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

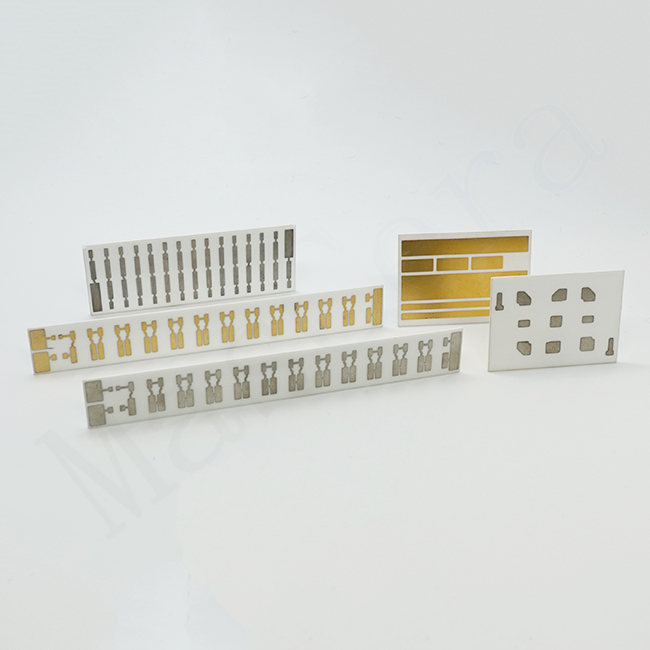

Direct Bonded Copper Dbc Ceramic Substrate

DBC(Direct Bonded Copper) is one of the main metallization for ceramic substrates. The copper foils can be directly bonded on single or double surfaces of ceramic substrates (alumina ceramic or aluminum nitride) without a middle layer, reducing the contact thermal resistance between the metal layer and the ceramic layer, getting better heat dissipcation capability.

Email Details

DBC substrates have not only the characteristics of high thermal conductivity, high electrical insulation, high mechanical strength, and low expansion of ceramics of ceramics, but also the high electrical conductivity and excellent soldering performance of oxygen-free copper, and can be carved into various graphics like a PCB circuit board.

Any inquiry please email info@mascera-tec.com or call +86 13860446139