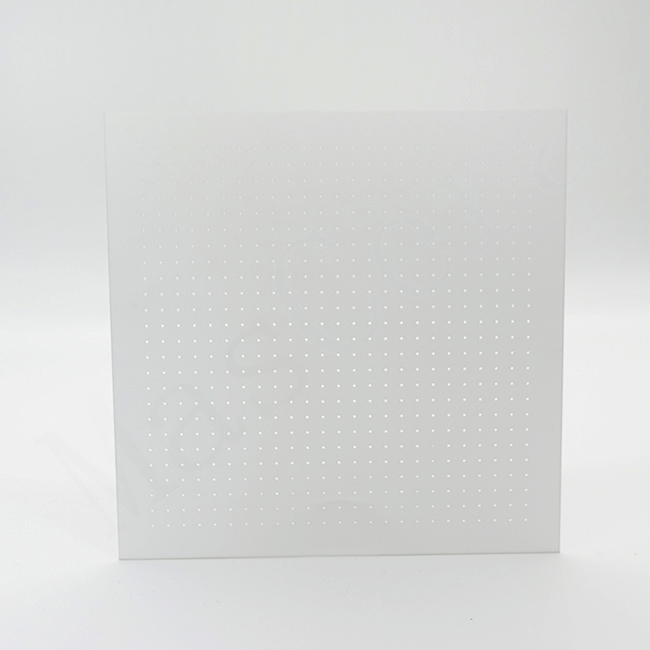

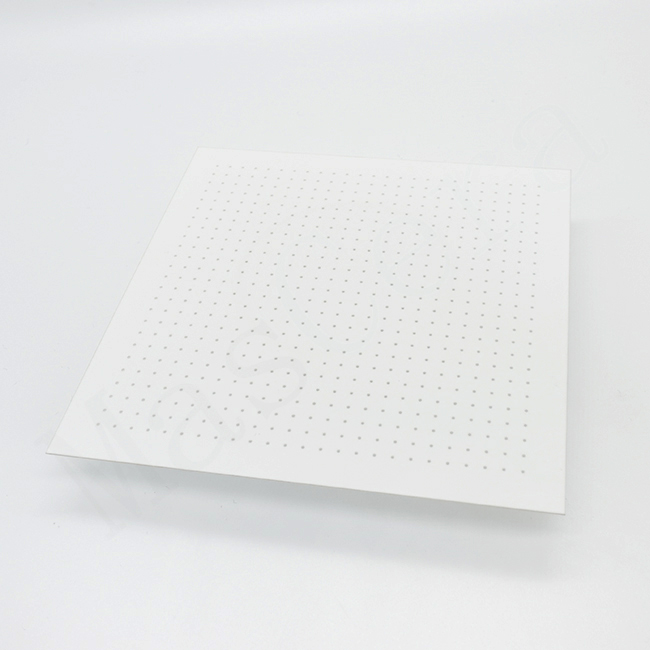

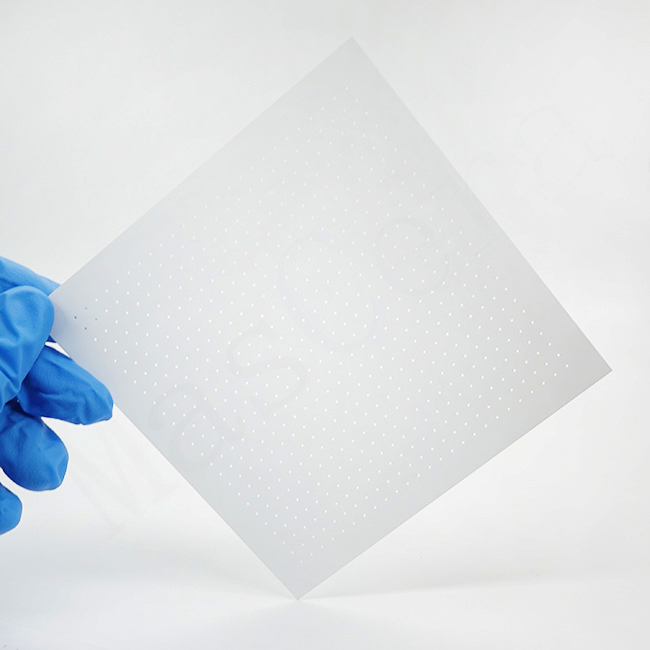

Laser-Drilled Alumina (Al2O3) Ceramic Substrates

- MSJ/CS-008

- Alumina Ceramic

- Customizable

- 10 pcs per type

- Electronic Circuits or Modules

The Laser-Drilled 96% Alumina (Al2O3) Ceramic Substrates is a high-performance ceramic material widely used in high-tech industries such as electronics, electrical, and semiconductors. Alumina (Al2O3) substrate offers exceptional mechanical strength, wear resistance, and electrical insulation properties.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

The Laser-Drilled Alumina (Al2O3) Ceramic Substrates is commonly used in the manufacture of circuit boards, heat sinks, and electronic component packaging substrates. Due to its high thermal conductivity and low dielectric loss, this material effectively dissipates heat and minimizes electromagnetic interference, thereby enhancing the reliability and performance of electronic devices. The laser-drilled design provides greater design flexibility, allowing for complex circuit layouts and multi-layer integration on the alumina ceramic substrate.

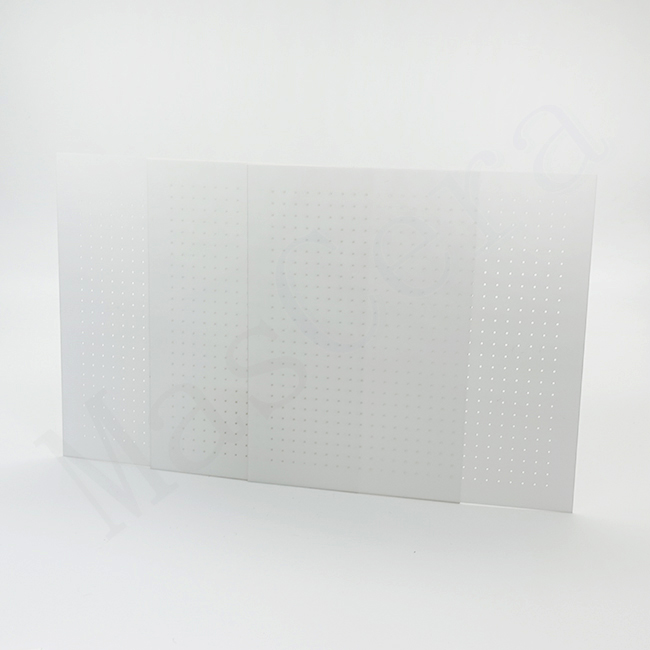

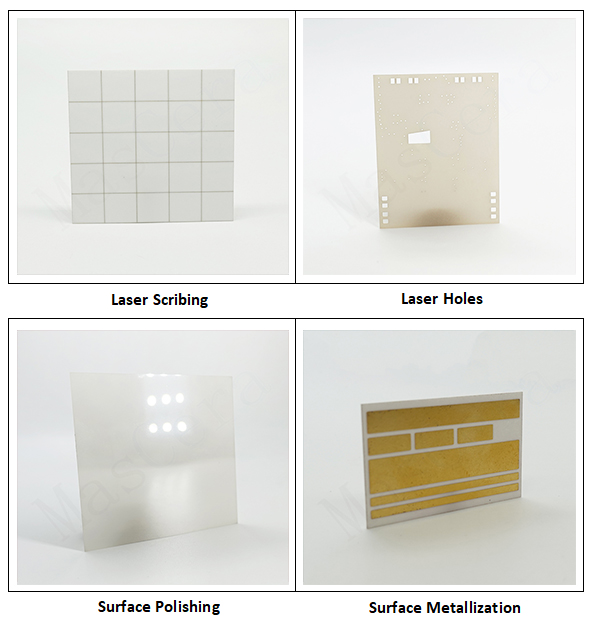

Mascera offers a variety of laser-drilled substrates in different specifications and dimensions, with the capability to customize hole sizes and layout designs according to specific customer requirements. Our production line features high precision, rapid processing, and excellent product stability. Additionally, we offer laser cutting, laser scribing, and polishing services. Customization inquiries are welcome.

96% Alumina General Dimension

| Length*Width(mm) | 110*110 / 101.6*101.6 / 114.3*114.3 / 120*120 / 127*127 / 109*130 / 130*140 / 140*190 |

| Thickness(mm) | 0.25 / 0.3 / 0.38 / 0.5 / 0.635 / 0.76 / 0.8 / 0.89 / 1 / 1.2 / 1.5 / 2 |

99.6% Alumina General Dimension

| Length*Width(mm) | 50.8*50.8 / 76.2*76.2 / 101.6*101.6 / 114.3*114.3 |

| Thickness(mm) | 0.254 / 0.38 / 0.6 / 0.635 |

Product Features

Excellent Electrical Performance

It boasts superior electrical insulation properties, making it suitable for high-voltage and high-frequency electronic devices.

Mechanical Strength

The high hardness and flexural strength of alumina ceramic enable it to withstand significant mechanical stress.

Thermal Stability

Exceptional high-temperature resistance allows the substrate to maintain stable performance even under prolonged exposure to heat.

Precision Perforated Design

The perforated substrate offers diverse mounting options, accommodating various complex electronic components and circuit design requirements.

Corrosion Resistance

With outstanding chemical stability, the substrate resists corrosion from various substances, thereby extending the product's lifespan.

Alumina Substrate Property Data

Material | Unit | 96% Al2O3 | 99.6% Al2O3 |

Purity | % | 96 | 99.6 |

Color | --- | White | White |

Density | g/cm3 | 3.7 | 3.9 |

Surface roughness | μm | 0.2-0.75 | 0.05-0.15 |

Camber | length % | ≤3 | ≤3 |

Thermal conductivity | W/m.k (@25°C) | 24 | 29 |

Thermal expansivity | ×10-6/°C | 6-8 | 6-8 |

Bending strength | MPa | ≥350 | ≥450 |

Dielectric constant | W/m.k (@1MHz 25°C) | 9-10 | 9.7-10.5 |

Dielectric loss | KV/mm (@1MHz 25°C) | ≥17 | ≥17 |

Volume resistivity | W/m.k (@25°C) | ≥10^14 | ≥10^14 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |