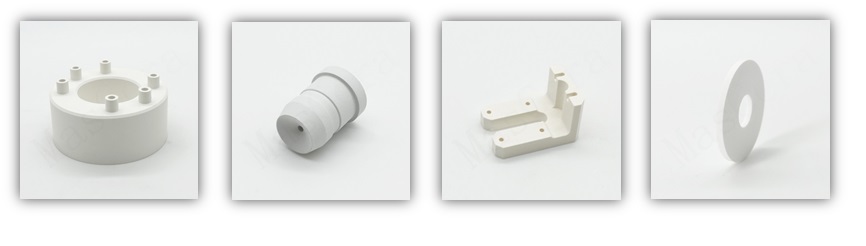

Hot-Pressed Boron Nitride (HPBN)

Hot Pressed Boron Nitride (HPBN) is a high-performance ceramic widely used in demanding environments requiring exceptional thermal and electrical stability. Due to its unique structure, it remains stable under extreme conditions, making it ideal for applications such as vacuum furnaces, protective gas atmospheres, and high-temperature metal processing. Its excellent machinability allows for the precise fabrication of complex components, enabling customization for various industrial needs. Additionally, its chemical inertness and resistance to molten metals make it a reliable choice for crucibles, insulators, and other critical parts in high-purity applications.

Hot Pressed Boron Nitride (HPBN) is a high-performance ceramic widely used in demanding environments requiring exceptional thermal and electrical stability. Due to its unique structure, it remains stable under extreme conditions, making it ideal for applications such as vacuum furnaces, protective gas atmospheres, and high-temperature metal processing. Its excellent machinability allows for the precise fabrication of complex components, enabling customization for various industrial needs. Additionally, its chemical inertness and resistance to molten metals make it a reliable choice for crucibles, insulators, and other critical parts in high-purity applications.

Properties

+Outstanding thermal shock resistance | +Easily machinable for precision fabrication |

| +Low density and lightweight | +Usable at extremely high temperatures in vacuum or inert gas |

| +Excellent thermal conductivity | +High electrical resistivity |

| +High dielectric breakdown strength | +Non-wetting with molten metals |

| +Chemically inert |

Material Grades

HPBN-BN-99

BN-99 is a ceramic material made from high-purity boron nitride. It is white in color, with excellent electrical insulation, high-temperature resistance, and chemical inertness, along with good thermal conductivity and high thermal shock resistance. It is widely used in semiconductor, metal smelting, and aerospace fields. Common applications include insulation sleeves for electrodes in vacuum sintering furnaces and atmosphere furnaces, thermocouple protection sleeves, insulating components in vacuum coating equipment, insulating components in polycrystalline silicon ingot furnaces, and molds for shaping metal or glass.

HPBN-BN-997

BN-997 is made of 99.7% boron nitride, white and offering outstanding thermal conductivity and high-temperature performance, making it widely used in metal processing. Due to its high purity, it does not bond or contaminate products and withstands repeated high- and low-temperature impacts and corrosion, thus extending its service life. It is suitable for sintering and melting alloys, aluminum nitride substrates, silicon nitride substrates, transparent ceramics, aluminum nitride powders, and rare earth materials.

HPBN-BN-A

BN-A is a boron nitride material compounded with aluminum and silicon, light grey. It has excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. Due to its Al and Si composition, it has significantly enhanced mechanical strength compared to high-purity boron nitride, making it more suitable for powder metallurgy applications, such as high-temperature furnace components, molten metal transport tubes, and nozzles.

HPBN-BN-B

BN-B is a boron nitride material compounded with aluminum and zirconium, light grey. It possesses excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. With the addition of Al and Zr, it has enhanced mechanical strength compared to high-purity boron nitride, making it more suitable for powder metallurgy applications, including high-temperature furnace components, various devices for molten metals or glass, molten metal transport tubes, and nozzles.

HPBN-BN-C

BN-C is a boron nitride material compounded with silicon carbide, with a grey-green color. It offers excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. The addition of SiC significantly increases its mechanical strength compared to high-purity boron nitride, making it ideal for metal casting applications, such as high-temperature furnace components, various devices for molten metal or glass, molten metal transport tubes, and nozzles.

HPBN-BN-D

BN-D is a boron nitride material compounded with zirconium oxide, dark grey. It has excellent electrical insulation and heat resistance, along with good thermal stability and chemical corrosion resistance. The ZrO2 enhances its mechanical strength, especially compressive strength, making it more suitable for metal casting applications, including high-temperature furnace components, various devices for molten metal or glass, high-temperature casting components, molten metal transport tubes, and nozzles.

HPBN-BN-E

BN-E is a boron nitride material compounded with aluminum nitride, with a grey-green color. It has excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. Due to its AlN composition, it has significantly enhanced mechanical strength and higher thermal conductivity than high-purity boron nitride, making it suitable for powder metallurgy applications, including high-temperature furnace components, metal evaporation boats, molds for precious or specialty alloy casting, various devices for molten metal or glass, high-temperature casting components, molten metal transport tubes, and nozzles.

HPBN-BN-S

BN-S is a boron nitride material compounded with silicon nitride, with a dark grey. color. It offers excellent electrical insulation and heat resistance, as well as good thermal stability and chemical corrosion resistance. Thanks to its Si3N4 composition, it has the highest compressive strength among all boron nitride composite materials. It is well-suited for non-insulating structural components, particularly as high-temperature supports, components subject to load, molten metal transport, nozzles, and separating rings in horizontal continuous casting.

Data Sheet

| ltem | Unit | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E | BN-S |

| Main Content | - | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AIN | BN+Si3N4 |

| Color | - | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green | Dark Grey |

| Density | g/cm³ | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 | 2.2-2.3 |

| Flexural Strength | Mpa | 18 | 30 | 65 | 65 | 80 | 90 | 90 | 150 |

| Compressive Strength | Mpa | 45 | 85 | 145 | 145 | 175 | 220 | 220 | 380 |

| Thermal Conductivity | W/Mk | 35 | 40 | 35 | 35 | 45 | 30 | 85 | 40 |

| Thermal Expansion Coefficient(@25-1000°C) | 10-⒍/K | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 | 2.7 |

Max. Service Temp. @Air Condition | °C | 900 | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. @Vacuum Condition | °C | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

Max. Service Temp. @Inert Gas Condition | °C | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 | 1750 |

| Electrical Resistivity | Ω.cm | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 | >1013 |

Applications

Heat treatment supports and fixtures.

Nozzles for metal powder gas atomization and molten metal spraying.

High-temperature and high-voltage electrical insulators.

Support components for vacuum and inert gas furnaces.

Crucibles and containers for high-purity molten metals and glass processing.

Break rings and molds for continuous casting of metals.

Related Products