Silicon Carbide Ceramic

-

Silicon Carbide Ballistic Ceramic Plate For Physical Protection

Silicon carbide bulletproof plates are used for providing ballistic protection, made from silicon carbide powder with high hardness and wear resistance.In the manufacturing process, the silicon carbide powder is heated to high temperature to crystallize and form an extremely dense ceramic structure. This structure makes the silicon carbide bulletproof plates extremely hard, allowing them to effectively block the penetration of bullets or other fragments. Compared to other materials, silicon carbide bulletproof plates are lighter, thinner, as well as more durable and reliable.

Email Details

Mascera is a professional manufacturer of industrial precision ceramics, specializing in customized production of Silicon carbide ceramic products.

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Sic Silicon Carbide Ceramic Tray Plates For Icp Etching

The wafer carriers utilized in epitaxial growth processes are subjected to high temperatures and rigorous chemical cleaning. Mascera offers high-purity silicon carbide ceramic tray plates that provide exceptional heat resistance, uniform thermal distribution for consistent epi layer thickness and resistance, and robust chemical resistance.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Reaction Bonded Silicon Carbide burner tubes for industrial furnace

High-temperature furnace tubes produced from reaction-bonded silicon carbide (SiSiC) can be used up to 1250 degrees Celsius. With a resistance to cracking and an extended lifespan, they are ideal for kiln applications. These tubes are widely employed in industrial furnaces with both direct fire heating and indirect heating systems utilizing radiant tubes. Mascera can customize reaction-bonded burner tubes and nozzles according to customer requirements for high-temperature furnaces.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Silicon Carbide Ceramic Mechanical Seal

Silicon carbide in mechanical seal assemblies yields numerous benefits, including enhanced performance, extended seal lifespan, reduced maintenance expenses, and decreased operating costs for rotating equipment such as turbines, compressors, and centrifugal pumps. These seals help minimize the risk of leakage and catastrophic failure, ensuring environmental protection against fugitive emissions. Additionally, Silicon carbide seals contribute to lower energy consumption by reducing friction during start-up and shutdown procedures, as well as minimizing wear and erosion during operation. Silicon carbide seals exhibit exceptional durability, thereby increasing the mean time between failures and resulting in improved productivity and reduced total cost of ownership for processing equipment.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

High Precision Machining Silicon Carbide Ceramic Bushing

Silicon carbide ceramic not only has excellent mechanical properties at room temperature, such as high bending strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low friction coefficient, but also outstanding mechanical properties (strength, creep resistance) at high temperature. Silicon carbide ceramic is widely used in automobile, mechanical and chemical industry, semiconductor, space technology, microelectronics, energy, papermaking and other fields, which has become an irreplaceable wear resistant and refractory material.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Hot

Sintered Silicon Carbide Sic Ceramic

Silicon carbide ceramic not only has excellent mechanical properties at room temperature, such as high bending strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low friction coefficient, but also outstanding mechanical properties (strength, creep resistance) at high temperature. Silicon carbide ceramic is widely used in automobile, mechanical and chemical industry, semiconductor, space technology, microelectronics, energy, papermaking and other fields, which has become an irreplaceable wear resistant and refractory material.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Silicon Carbide Crucibles for Laboratory Glass and Foundry Use

Mascera offers high temperature ceramic crucibles made from pressureless sintered silicon carbide (SSiC), designed for extreme conditions in metallurgy, laboratories, and high-purity manufacturing. These silicon carbide crucibles combine high strength, excellent thermal shock resistance, and exceptional corrosion resistance, making them a reliable solution for high-temperature applications.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139 -

Hot

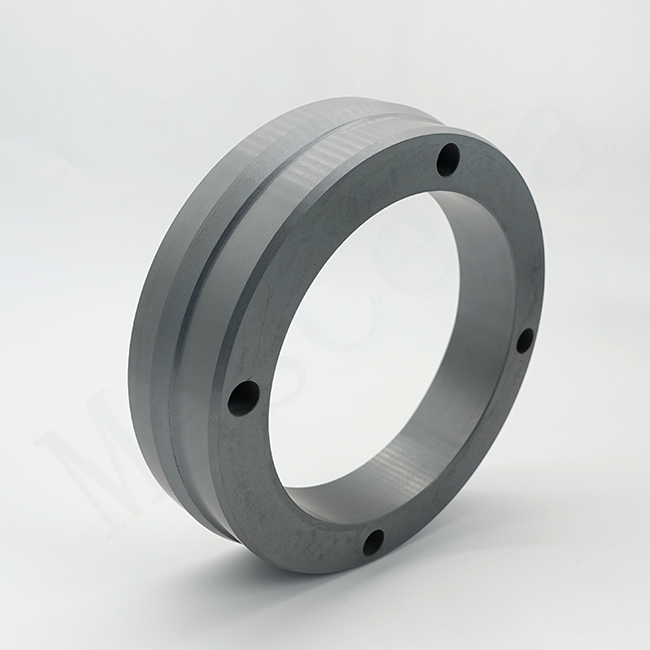

Sic Silicon Carbide Ceramic Seal Ring

Silicon carbide ceramic / SiC ceramic is an ideal material for mechanical seal rings because it is a lightweight ceramic material with high strength properties comparable to diamond. The superior abrasion and corrosion resistance are also important reasons that people choose silicon carbide seal rings. Silicon carbide seal rings will have good sealing performance even under acid or alkali environment. Silicon carbide seal rings also have high heat resistance and good thermal shock resistance, the performance of wear resistance and strength are still excellent in high temperature.

Email Details

Any inquiry please email info@mascera-tec.com or call +86 13860446139