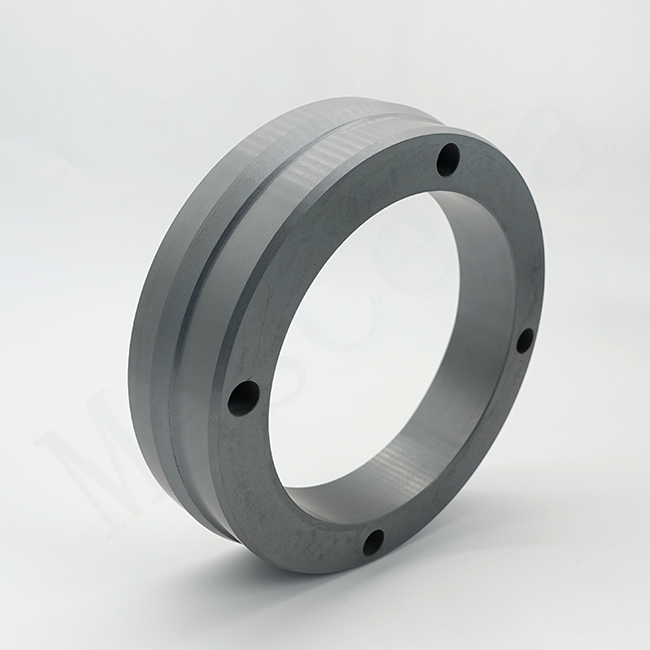

Sic Silicon Carbide Ceramic Tray Plates For Icp Etching

- MSJ/SC-004

- silicon carbide

- customized

- 5 pcs per type

- ICP etching

The wafer carriers utilized in epitaxial growth processes are subjected to high temperatures and rigorous chemical cleaning. Mascera offers high-purity silicon carbide ceramic tray plates that provide exceptional heat resistance, uniform thermal distribution for consistent epi layer thickness and resistance, and robust chemical resistance.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

The wafer carriers utilized in epitaxial growth processes are subjected to high temperatures and rigorous chemical cleaning. Mascera offers high-purity silicon carbide ceramic tray plates that provide exceptional heat resistance, uniform thermal distribution for consistent epi layer thickness and resistance, and robust chemical resistance.

The wafer carriers utilized in epitaxial growth processes are subjected to high temperatures and rigorous chemical cleaning. Mascera offers high-purity silicon carbide ceramic tray plates that provide exceptional heat resistance, uniform thermal distribution for consistent epi layer thickness and resistance, and robust chemical resistance.Non-oxide ceramic, silicon carbide ceramic (SiC) is an superhard material which has moh's hardness up to 9.5. Silicon carbide ceramic not only has excellent mechanical properties at room temperature, such as high bending strength, excellent oxidation resistance, good corrosion resistance, high wear resistance and low friction coefficient, but also outstanding mechanical properties (strength, creep resistance) at high temperature, the high temperature strength can be maintained up to 1600°C, which is the best among all ceramic materials. The oxidation resistance of silicon carbide ceramic is also the best among all non-oxide ceramics.

Mascera produced silicon carbide ceramics in two forms, sintered silicon carbide (SSiC) and reaction bonded silicon carbide (SiSiC).

Sintered silicon carbide ceramic is produced by utilizing high-purity and nano-grade raw powders, which are sintered at a high temperature ranging from 2100℃ to 2200℃. This sintering process leads to densification of the green body and approximately 20% shrinkage. On the other hand, reaction-bonded silicon carbide utilizes micron-sized silicon carbide powder and is sintered at a temperature range of 1450℃ to 1700℃. Unlike sintered silicon carbide, reaction-bonded silicon carbide does not undergo shape shrinkage during the sintering process.

The higher sintering temperature of sintered silicon carbide results in improved performance characteristics, including higher density, increased strength, and enhanced resistance to oxidation and corrosion. For applications that do not require such high-performance properties, reaction-bonded silicon carbide is a more cost-effective choice

Main properties of silicon carbide ceramic

High strength in high temperature

High-temperature oxidation resistance

Excellent wear resistance

Low thermal expansion coefficient

High thermal conductivity

Excellent thermal shock resistance

High hardness

Light weight because of low density

Good corrosion resistance

Typical applications of silicon carbide ceramics

Mechanial seal rings

Balls, seats, liners for valve

Kiln furniture

Heat exchangers

Fixed and moving turbine components

Grinding media

Military bulletproof plates

Components for burners

Ceramic bearings

Material Data Sheet

| Item | Unit | Technical parameters | |

|---|---|---|---|

| Materail | -- | SSiC | SiSiC |

| Color | -- | Black | Black |

| Density | g/cm3 | 3.12 | 3.06 |

| Water Absorption | % | 0 | 0 |

| HRA | -- | ≥92 | ≥90 |

| Modulus of Elasticity | Gpa | 400 | 350 |

| Flexural Strength (@R.T.) | Mpa | 359 | 300 |

| Compressive Strength (@R.T.) | Mpa | ≥2200 | 2000 |

| Thermal Conductivity (@R.T.) | W/Mk | 110 | 100 |

Coefficient Of Thermal Expansion (20-1000℃) | 10-6/℃ | 4.0 | 4.0 |

| Max. Working Temperature | ℃ | 1500 | 1300 |

Available shapes of silicon carbide ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |