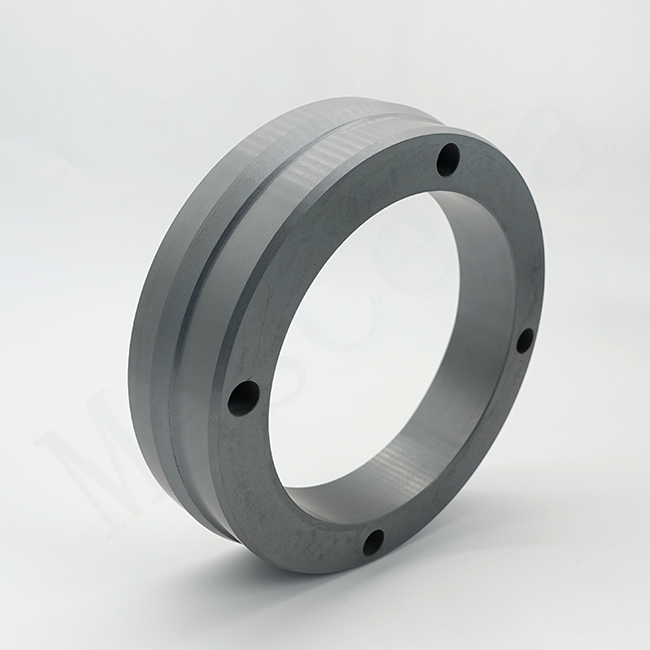

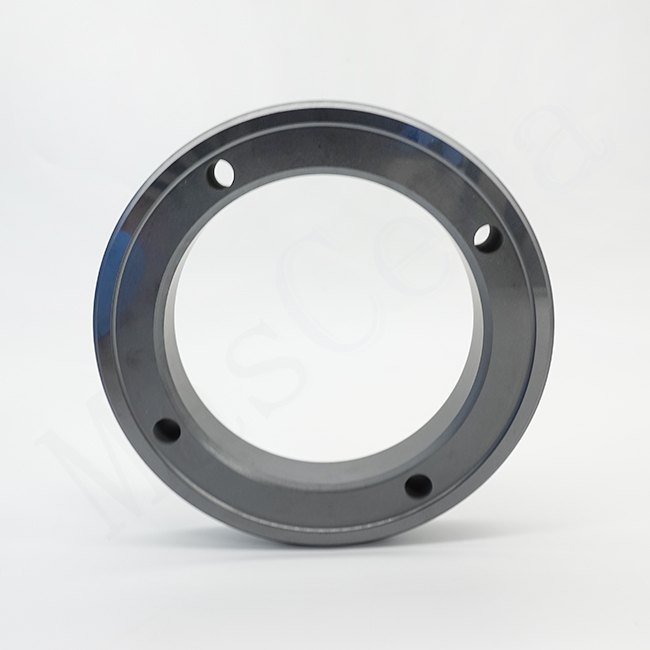

Silicon Carbide Ceramic Mechanical Seal

- MSJ/SC-001

- silicon carbide

- customized

- 10 pcs per type

- wear resistant ceramic rings for pumps

Silicon carbide in mechanical seal assemblies yields numerous benefits, including enhanced performance, extended seal lifespan, reduced maintenance expenses, and decreased operating costs for rotating equipment such as turbines, compressors, and centrifugal pumps. These seals help minimize the risk of leakage and catastrophic failure, ensuring environmental protection against fugitive emissions. Additionally, Silicon carbide seals contribute to lower energy consumption by reducing friction during start-up and shutdown procedures, as well as minimizing wear and erosion during operation. Silicon carbide seals exhibit exceptional durability, thereby increasing the mean time between failures and resulting in improved productivity and reduced total cost of ownership for processing equipment.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Mechanical seals are required to function effectively in demanding operating conditions, including high speeds, temperatures, and pressures, all while maintaining resistance to corrosion and wear. Technical ceramics offer the ideal combination of toughness, stiffness, flexural strength, hardness, and corrosion resistance for mechanical seals. They are particularly well-suited for dry gas seal assemblies, which necessitate minimal deflection at high speeds and low thermal expansion at elevated temperatures.

Silicon carbide in mechanical seal assemblies yields numerous benefits, including enhanced performance, extended seal lifespan, reduced maintenance expenses, and decreased operating costs for rotating equipment such as turbines, compressors, and centrifugal pumps. These seals help minimize the risk of leakage and catastrophic failure, ensuring environmental protection against fugitive emissions. Additionally, Silicon carbide seals contribute to lower energy consumption by reducing friction during start-up and shutdown procedures, as well as minimizing wear and erosion during operation. Silicon carbide seals exhibit exceptional durability, thereby increasing the mean time between failures and resulting in improved productivity and reduced total cost of ownership for processing equipment.

Mascera produced silicon carbide ceramics in two forms, sintered silicon carbide (SSiC) and reaction bonded silicon carbide (SiSiC).

Sintered silicon carbide ceramic is made of high-purity and nano-grade raw powders and sintered at a high temperature of 2100℃-2200℃, the sintering process will densify the green body and cause shrinkage approximately 20%; reaction boned silicon carbide uses micron-sized silicon carbide powder, the sintering temperature is 1450℃-1700℃, there is no shape shrinkage during sintering. The higher sintering temperature makes sintered silicon carbide having better performance, such as higher density, higher strength, better resistance to oxidation and corrosion; for applicatons which don't have so high properties requirement, reaction bonded silicon carbide is more cost effective.

Main properties of silicon carbide ceramic

High strength in high temperature

High-temperature oxidation resistance

Excellent wear resistance

Low thermal expansion coefficient

High thermal conductivity

Excellent thermal shock resistance

High hardness

Light weight because of low density

Good corrosion resistance

Material Data Sheet

| Item | Unit | Technical parameters | |

|---|---|---|---|

| Materail | -- | SSiC | SiSiC |

| Color | -- | Black | Black |

| Density | g/cm3 | 3.12 | 3.06 |

| Water Absorption | % | 0 | 0 |

| HRA | -- | ≥92 | ≥90 |

| Modulus of Elasticity | Gpa | 400 | 350 |

| Flexural Strength (@R.T.) | Mpa | 359 | 300 |

| Compressive Strength (@R.T.) | Mpa | ≥2200 | 2000 |

| Thermal Conductivity (@R.T.) | W/Mk | 110 | 100 |

Coefficient Of Thermal Expansion (20-1000℃) | 10-6/℃ | 4.0 | 4.0 |

| Max. Working Temperature | ℃ | 1500 | 1300 |

Available shapes of silicon carbide ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Company Introducton

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a China supplier which specialized in custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to 40 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

With expertise of material properties and machining technique, Mascera is able to give our customers the most valuable solutions for their specific applications and cooperate from prototype development to mass production. It is our honor that our technical ceramics components are used by some research institutes and high-tech enterprises, and make small contribution for technology innovation.