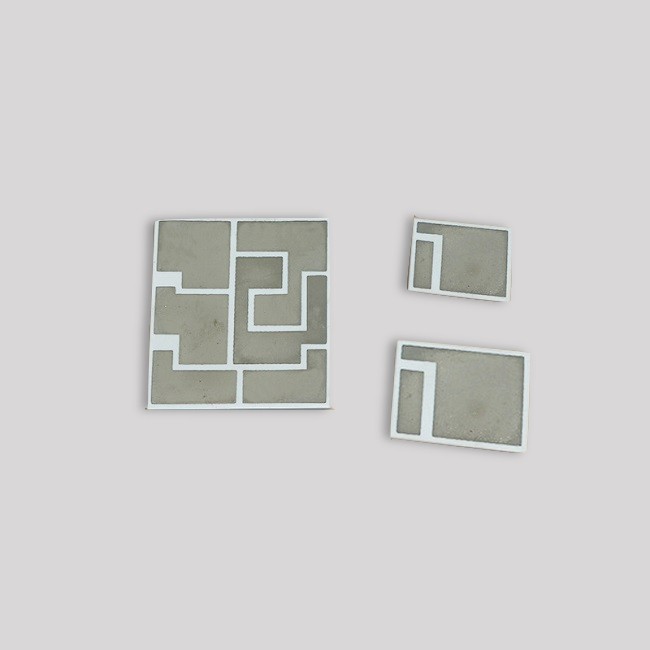

Direct Bonded Copper Dbc Ceramic Substrate

- MSJ/CS-003

- metallized ceamic substrate

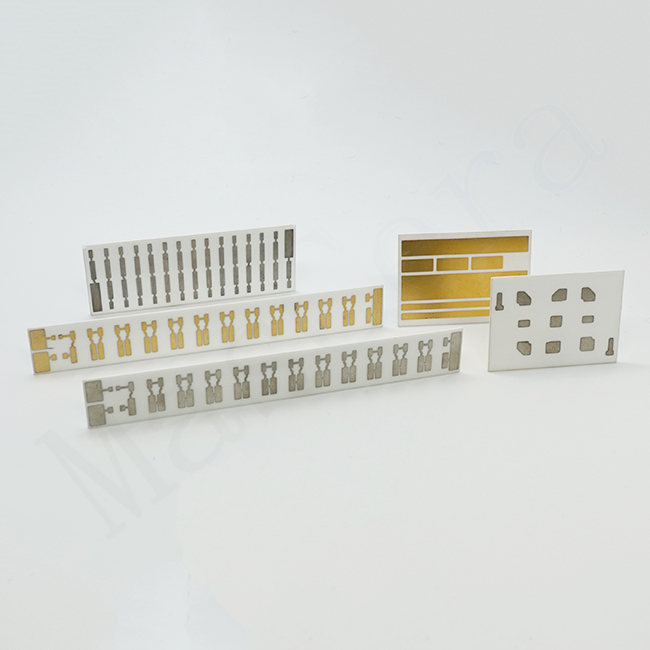

- customized as per required specification

- 100pcs

- ceramic substrate for electronic circuit or modules

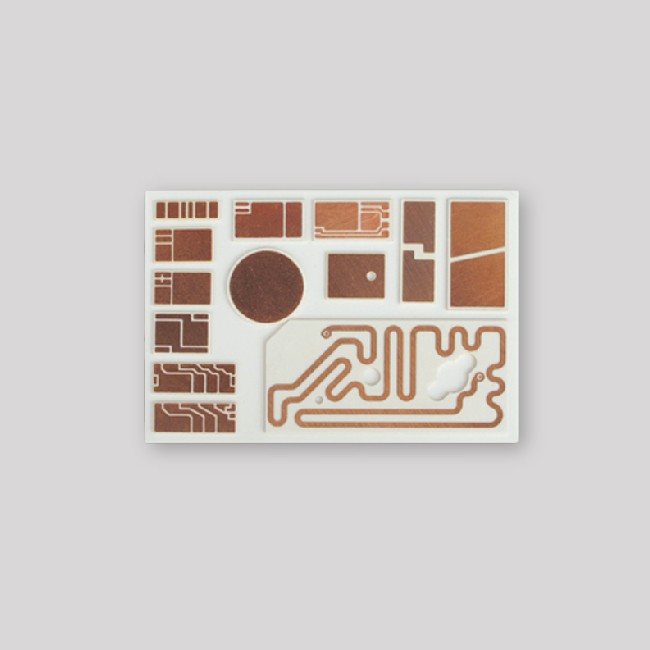

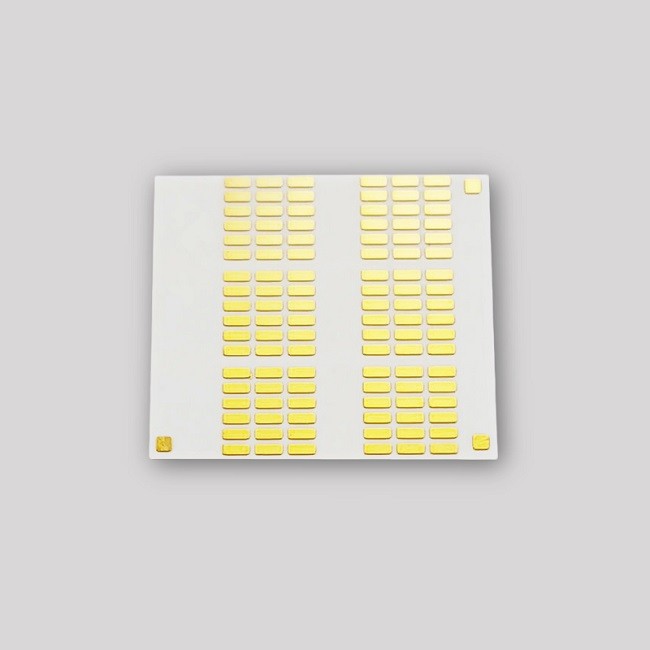

DBC(Direct Bonded Copper) is one of the main metallization for ceramic substrates. The copper foils can be directly bonded on single or double surfaces of ceramic substrates (alumina ceramic or aluminum nitride) without a middle layer, reducing the contact thermal resistance between the metal layer and the ceramic layer, getting better heat dissipcation capability.

DBC substrates have not only the characteristics of high thermal conductivity, high electrical insulation, high mechanical strength, and low expansion of ceramics of ceramics, but also the high electrical conductivity and excellent soldering performance of oxygen-free copper, and can be carved into various graphics like a PCB circuit board.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

DBC(Direct Bonded Copper) is one of the main metallization for ceramic substrates. The copper foils can be directly bonded on single or double surfaces of ceramic substrates (alumina ceramic or aluminum nitride) without a middle layer, reducing the contact thermal resistance between the metal layer and the ceramic layer, getting better heat dissipcation capability.

DBC substrates have not only the characteristics of high thermal conductivity, high electrical insulation, high mechanical strength, and low expansion of ceramics of ceramics, but also the high electrical conductivity and excellent soldering performance of oxygen-free copper, and can be carved into various graphics like a PCB circuit board.

DBC substrates are widely applied in high-speed rail, automotive electronics, industrial electronics, communications, military, aerospace and other fields. Benefiting from the excellent current carrying capacity, voltage endurance capability and heat dissipation capacity, DBC substrates are generally used in areas with relatively large currents and large resistances, such as high-power modules and high-power devices.

Feature of DBC Substrates

High mechanical strength, mechanically stable shape;

Excellent heat dissipation capability

Excellent current carrying capacity

Good electrical insulation

Strong bonding strength between ceramic substrate and copper layer

Much better thermal cycling capability (up to 50k cycles)

Can be etched like PCB boards to get required graphics

The process is simple, no need for MO-MN metallization process

Features of DBC VS DPC

| Item | DBC | DPC |

|---|---|---|

Thickness of copper | thick | thin |

Width of line | thick | thin |

Spacing of line | big | small |

Graphics accuracy6 | high | low |

Surface roughness | normal | good |

Via holes | Available | Unavailable |

Use for high current devices (IGBT etc.) | suitable | Not suitable |

Material Properties for Ceramic 96% Alumina Ceramic

| Item | Unit | Technical Parameters |

|---|---|---|

Material Type | --- | 96% AL2O3 Ceramic |

Purity | --- | 96% |

Color | --- | White |

Density | g/cm3 | ≥3.72 |

Warpage | --- | ≤3‰*Length |

Water Absorption | --- | 0% |

Flexural Strength | Mpa | ≥350 |

Thermal conductivity (25℃) | W/M.K | ≥24 |

Thermal expansion coefficient (20~300℃) | 10-6mm/℃ | 8 |

Maxim Operation Temp. | ℃ | 1650 |

Dielectric constant (1MHz&25℃) | --- | 9~10 |

Dielectric Loss (1MHz&25℃) | --- | 0.0003 |

Dielectric strength | KV/mm | 17 |

Volume resistivity | Ω.cm | 1014 |

Typical Application of DBC Substrates

Power semiconductor modules; semiconductor refrigerator, electronic heating device, power control circuits, power hybrid circuits

Smart power modules, high frequency switch, solid state relays

Automobile electronics, military and aerospace electronics

Solar panel assemblies, telecommunication exchange and receiving system, laswer electronics

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery