96 Al2O3 Alumina Ceramic Substrates

- MSJ/CS-001

- 96% alumina ceramic

- customized

- 100 pcs per type

- electronic circuits or modules

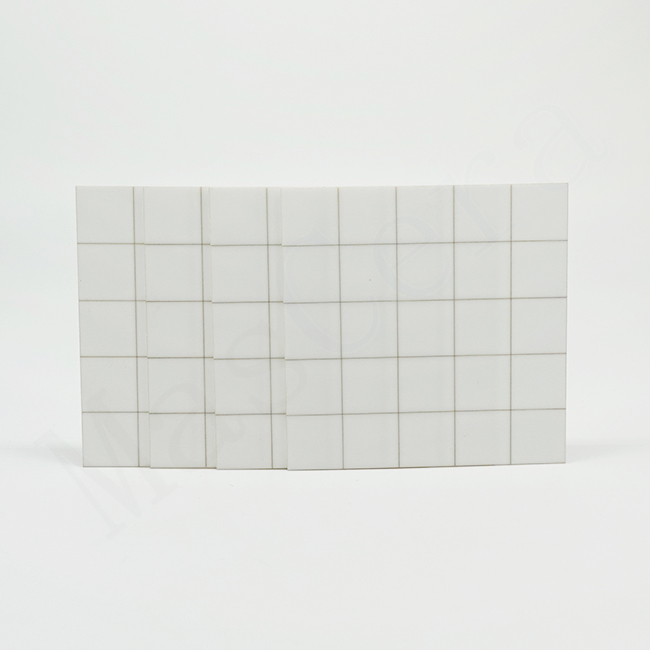

96% Alumina substrates are the most cost-effective and commonly used ceramic substrate for thick film electronics or power powdules, they are made of electrically insulated 96% alumina (al2o3) ceramic. Alumina substrates have advantages of good electrical insulation, low dielectric properties, good heat resistance and wear resistance. The good thermal conductivity will help electronic modules to dissipate heat efficiently. The shape is stable because of the high strength and good durability, the surface is smooth and flatness is as good as 2‰ of dimensions.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

96% Alumina substrates are the most cost-effective and commonly used ceramic substrate for thick film electronics or power powdules, they are made of electrically insulated 96% alumina (al2o3) ceramic. Alumina substrates have advantages of good electrical insulation, low dielectric properties, good heat resistance and wear resistance. The good thermal conductivity will help electronic modules to dissipate heat efficiently. The shape is stable because of the high strength and good durability, the surface is smooth and flatness is as good as 3‰ of length.

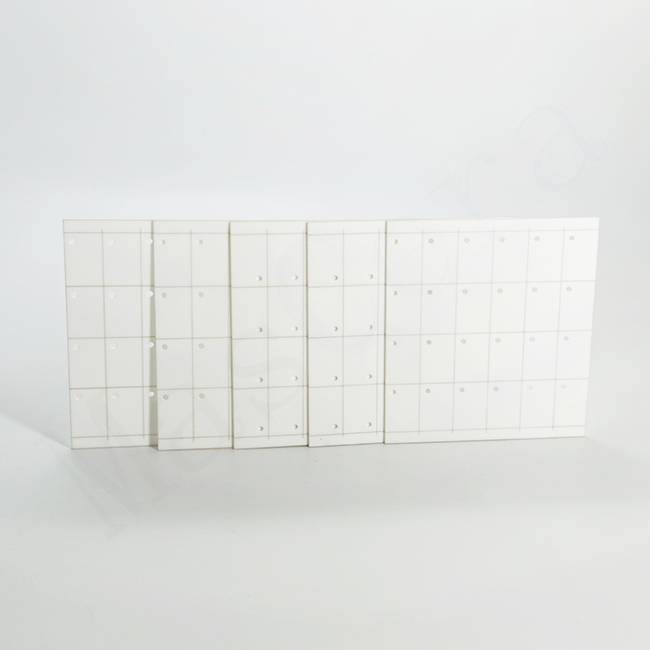

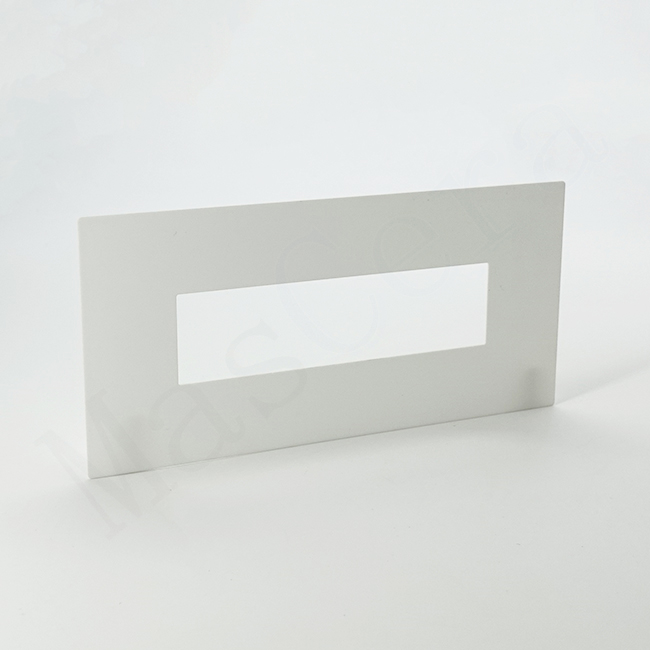

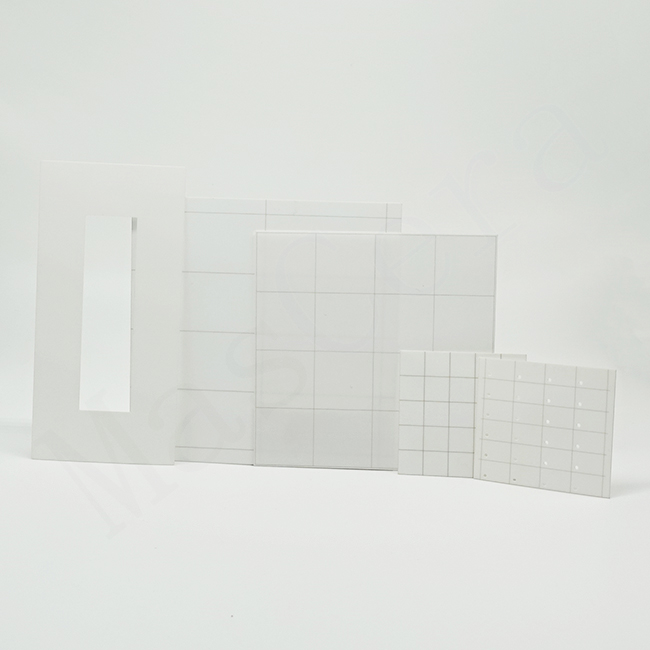

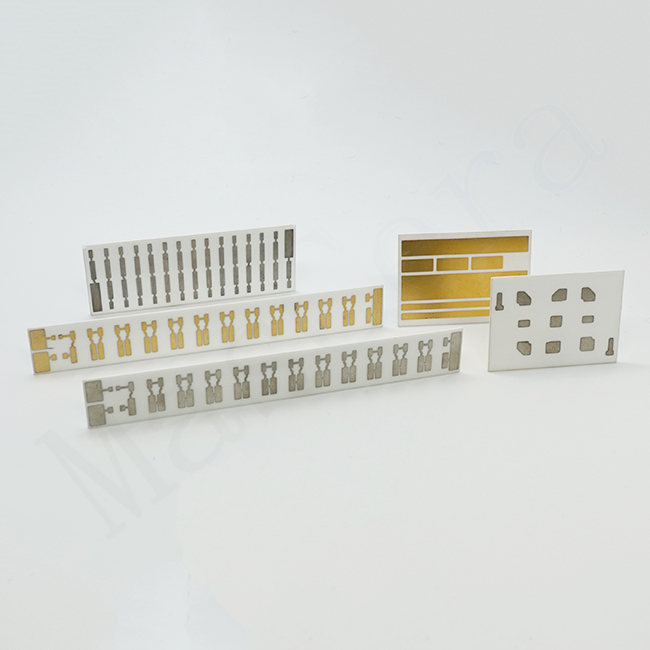

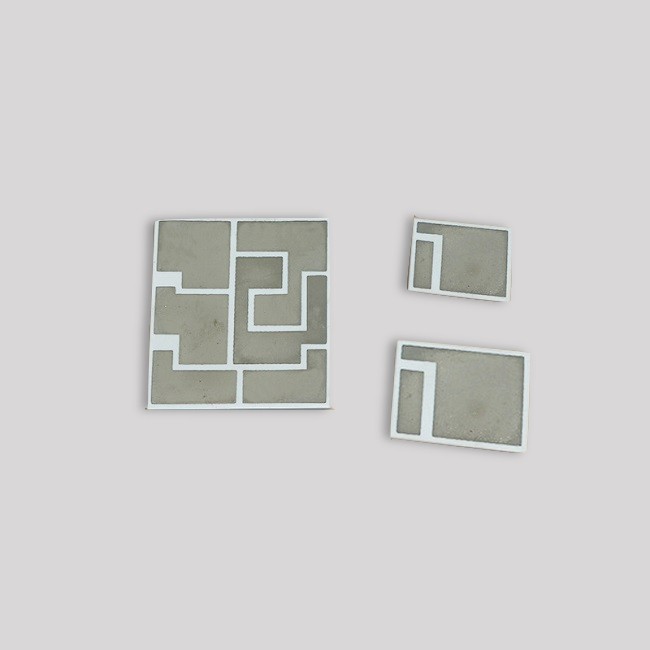

Mascera provides high-quality alumina substrates at competitive prices. Our production line includes capabilities for laser cutting, laser scribing, and hole drilling, allowing us to offer customized sizes and patterns to meet your specific requirements.

96% Alumina General Dimension

| Length*Width(mm) | 110*110 / 101.6*101.6 / 114.3*114.3 / 120*120 / 127*127 / 109*130 / 130*140 / 140*190 |

| Thickness(mm) | 0.25 / 0.3 / 0.38 / 0.5 / 0.635 / 0.76 / 0.8 / 0.89 / 1 / 1.2 / 1.5 / 2 |

Main Feature of Alumina Substrate

High mechanical strength

High hardness and durability

Good electrical insulation

Low dielectric constant and dielectric loss

High thermal conductivity

Excellent corrosion resistance

Non-toxic

Good surface flatness

Zero porosity

Low weight

Alumina Substrate Property Data

| ITEM | UNIT | PARAMETER |

|---|---|---|

| Al2O3 Purity | % | 96 |

| Color | ‐ | White |

| Density | g/cm3 | ≥3.72 |

| Warpage | --- | ≤3‰*Length |

| Water Absorption | % | 0 |

| Moh’s Hardness | ‐ | 9 |

| Fracture Toughness | Mpa.m1/2 | 3‐4 |

| Flexural Strength(at 25℃) | Mpa | ≥350 |

| Thermal Conductivity | W/m.k | ≥24 |

| Coefficient of Thermal Expansion(20~300℃) | 10‐6/℃ | 8 |

| Max working temperature | ℃ | 1650 |

| Dielectric Constant(1MHz, 25℃) | ‐ | 9~10 |

| Dielectric Loss(1MHz, 25℃) | ‐ | 0.0003 |

| Dielectric Strength | KV/mm | 17 |

| Volume resistivity | Ω.cm | 1014 |

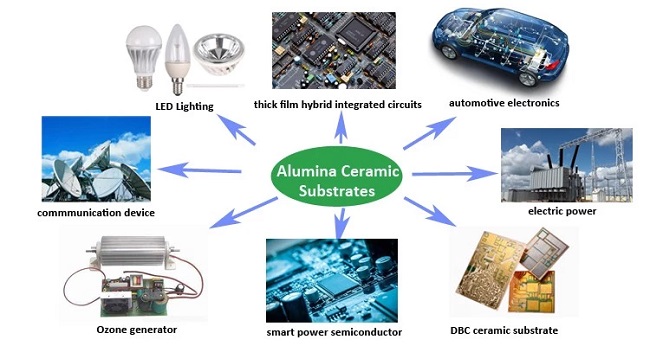

Typical Application of Alumina Substrate

Thanks to the good electrical properties and fast heat dissipation, alumina substrate is widely used in thick/thin film circuits, LED lighting, IGBT power modules, DBC substrates, automotive electronics, power resistors, and semiconductor refrigerators etc.

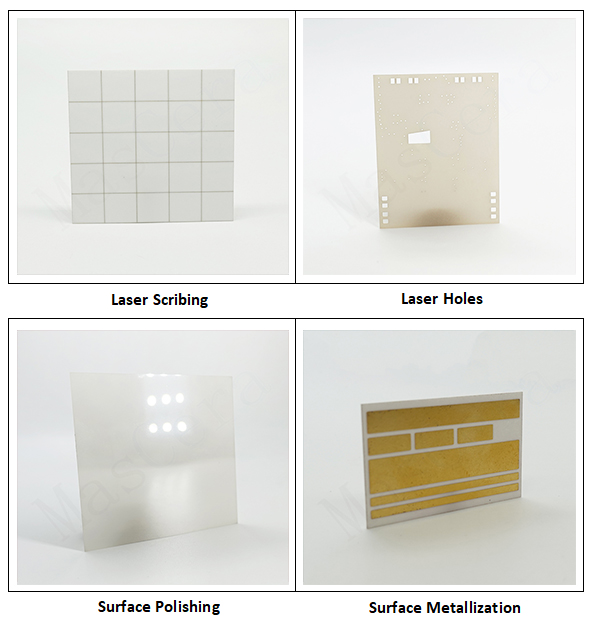

Processing Ability of Ceramic Substrates

Mascera has introduced laser machines in our production line and we are able to make laser cutting, laser scribing, hole drilling as per customers' request, size accuracy is high, processing speed is fast, product stability is good. For surface processing, polishing or DPC&DBC metallization can also be provided. Please send your design or demand details to us when you want a quotation from us.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery