MASCERA shipped over 1 million pieces of Al2O3 ceramic washer in Q1 2023

96% alumina ceramic washer are made of 96% alumina and are mainly used in electronic packaging for high-power diodes, transistors, MOS tubes, and small integrated circuits.These products are mainly sold to Europe and the Americas, and our first quarter shipments increased by 30% compared to the same period last year. This achievement reflects our focus on product quality, service quality, and customer relationship management.

high-power diodes, transistors, MOS tubes, and small integrated circuits.These products are mainly sold to Europe and the Americas, and our first quarter shipments increased by 30% compared to the same period last year. This achievement reflects our focus on product quality, service quality, and customer relationship management.

Our ceramic washer have the following performance advantages:

1.Excellent electrical insulation (1x1014 ~ 1x1015 Ω/cm)

2.High mechanical consistency (300 to 630 MPa0 = megapascals)

3.Very high compressive strength (2000-4000 MPa)

4.High hardness (15-19 GPa)

5.Good thermal conductivity (20-30 W/mK)

6.High corrosion resistance and wear resistance

7.Low volume mass (3.75-3.95 g/cm3)

8.Operating temperature without mechanical stress: 1000 ~ 1500℃

9.Good heat dissipation performance

10.Environmentally friendly and pollution-free

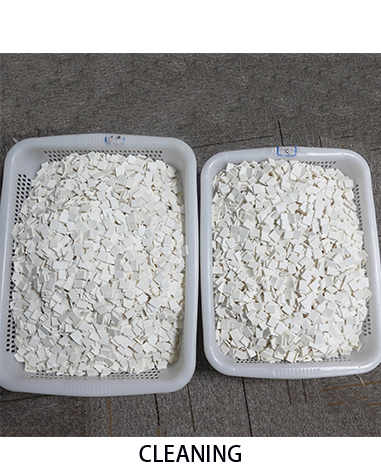

The main production process of our 96% alumina ceramic washer is as follows:

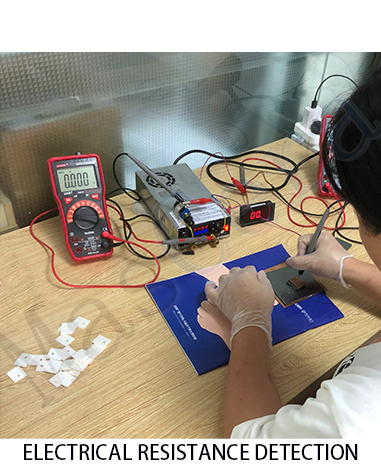

When it comes to quality control for ceramic washer, we use various methods to ensure that our products meet our expectations for quality and performance. Firstly, we have established a complete quality management system, including quality control standards, processes, and procedures, to ensure effective monitoring and management at every stage, from raw material procurement to production. Secondly, we use a range of testing equipment and methods to ensure that our products meet the required quality and performance standards. For example, we use a coordinate measuring machine and a caliper to measure and inspect the dimensions of our ceramic washer. We use a roughness tester to test the roughness of the ceramic surface, and we use circuit simulation to test the electrical resistance of the ceramic washer. In addition, we effectively monitor key control points during the production process to ensure the quality and performance of our products. For example, we inspect the quality of raw materials, monitor the production process, and classify and handle defective products. Finally, we have a complete after-sales service system that includes timely after-sales service and technical support.

meet our expectations for quality and performance. Firstly, we have established a complete quality management system, including quality control standards, processes, and procedures, to ensure effective monitoring and management at every stage, from raw material procurement to production. Secondly, we use a range of testing equipment and methods to ensure that our products meet the required quality and performance standards. For example, we use a coordinate measuring machine and a caliper to measure and inspect the dimensions of our ceramic washer. We use a roughness tester to test the roughness of the ceramic surface, and we use circuit simulation to test the electrical resistance of the ceramic washer. In addition, we effectively monitor key control points during the production process to ensure the quality and performance of our products. For example, we inspect the quality of raw materials, monitor the production process, and classify and handle defective products. Finally, we have a complete after-sales service system that includes timely after-sales service and technical support.

We have always been committed to technological innovation and product upgrades. As the electronic packaging industry continues to develop rapidly, we continue to expand our production capacity, introduce new equipment and technologies, and look forward to deepening cooperation with more customers to explore broader markets.

If you have any requirements, please feel free to contact us at any time.

EMAIL: info@mascera-tec.com PHONE:+86-13860446139