Advantages and disadvantages of zirconia ceramic blade and its application

Zirconia ceramic is a kind of ceramic material made from zirconia (ZrO2). The material has many characteristics, including chemical inertness, high thermal expansion, high abrasion resistance, crack growth resistance, excellent heat insulation, low thermal conductivity and so on. Moreover, it provides sharp edges and smooth surfaces because of its fine grain size, and zirconia has the highest flexural strength of any other ceramic material at room temperature. There is no doubt that blade made of zirconia ceramic has the following advantages:

abrasion resistance, crack growth resistance, excellent heat insulation, low thermal conductivity and so on. Moreover, it provides sharp edges and smooth surfaces because of its fine grain size, and zirconia has the highest flexural strength of any other ceramic material at room temperature. There is no doubt that blade made of zirconia ceramic has the following advantages:

1.High hardness and good wear resistance:

the Mohs hardness of zirconia ceramic knife is about 8.5, very close to the sapphire’ Mohs hardness of 9.

2.Excellent strength and toughness: zirconia industrial ceramic blade has relatively high strength, although its toughness is much lower comparing with some metals,but zirconia ceramic blade has the highest strength among all ceramic materials. . Zirconia ceramic blade can withstand large cutting force, impact and vibration to avoid cracks and breakage.

3、High heat resistance:

Zirconia ceramic blade can maintain the performance of sufficient hardness, wear resistance, strength and toughness, oxidation resistance, adhesion resistance and resistance to spread at high temperature. In industrial cutting, zirconia ceramic blade can support faster cutting speeds.

Meanwhile, due to the ceramic blade is sintered from zirconia, it determines its brittleness and low toughness. If the blade falls from ahigh place , it is prone to cause cracks, chips or breakage, ,so zirconia ceramic blade cannot be used to cut, smash, pry, pick or other ways.

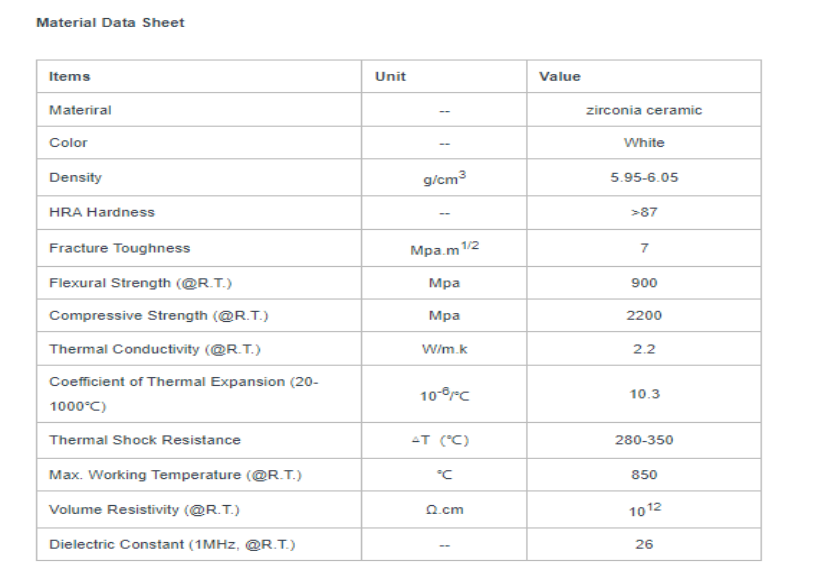

(Main performance parameters of zirconiaceramic )

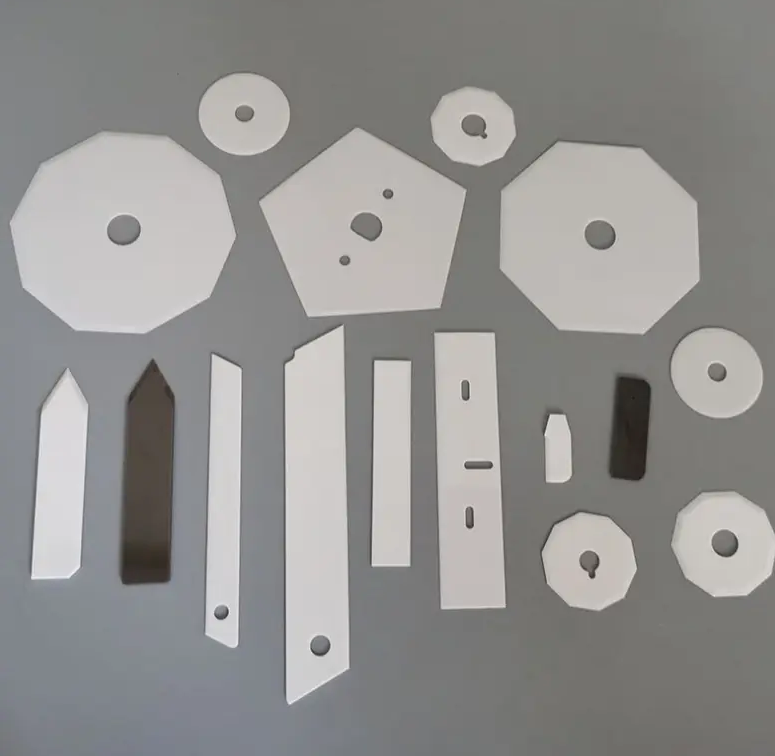

In daily life, the common tools using zirconia ceramic blade include table knife, scissors, razor, scalpel, box cutter and so on.

The use of these tools takes advantage of the excellent properties of zirconia ceramics, such as high strength, good wear resistance, no rust, no oxidation, good acid and alkali resistance, anti-static, no react with food, etc.. It can effectively avoid the release of metal ions in the tool.

In industrial field, ceramic blades are widely used for cutting of different materials, such as plastic film, fiber, cloth, carpet, foil film, empty hard geltain capsules etc. The outstanding wear resistance of zirconia ceramic blades can greatly reduce the frequency of replacement and maintenance cost, improve the cutting efficiency.