Application of Ceramic Heat Dissipation in Battery Cooling System

At present, the thermal management of power battery systems can be mainly divided into four categories: natural cooling, air cooling, liquid cooling, and direct cooling.

Among them, natural cooling is a passive thermal management method, while air cooling, liquid cooling, and direct cooling are active methods. The main difference between the three is the difference in heat exchange medium.

Traditional battery cooling system: To change the temperature difference between the battery core and the cooling system, liquid cooling system refrigeration is the most useful method.

How does ceramic heat dissipation apply to battery heat dissipation?

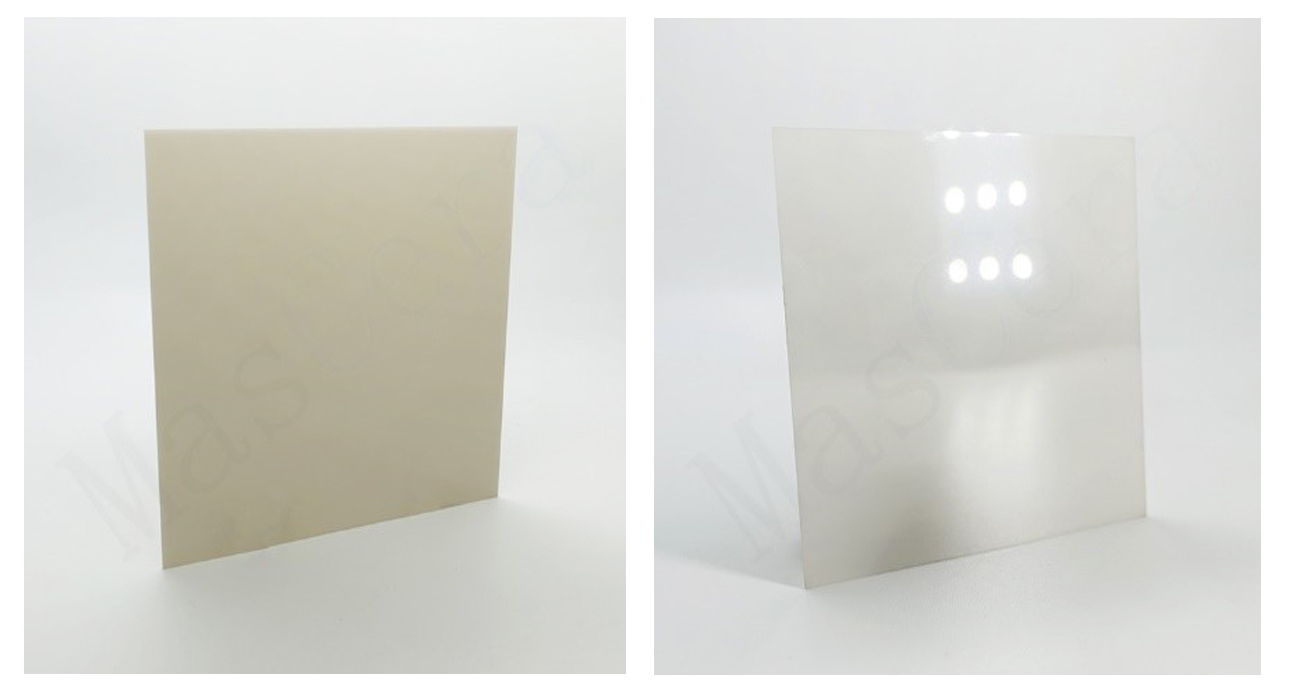

Replace insulating plastic materials with low thermal conductivity with ceramic materials with high thermal conductivity.

The research shows that rapid heat dissipation and temperature equalization can be achieved by using the high thermal conductivity and high insulation of ceramics. Aluminum nitride ceramic substrates are currently used more frequently.

Advantages of aluminum nitride ceramic substrate

Aluminum nitride ceramic substrate has high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity and low dielectric loss. It is an ideal large-scale integrated circuit heat dissipation substrate and packaging material.

1、High thermal conductivity

Aluminum nitride ceramics have very high thermal conductivity, with a theoretical value of up to 320W/m·K, which is much higher than traditional alumina ceramics. This makes aluminum nitride ceramics an ideal heat dissipation material, suitable for electronic devices, LED lighting, laser equipment and other fields, effectively improving the efficiency and life of the equipment.

2、Excellent electrical insulation

Aluminum nitride ceramics substrate have good electrical insulation, low dielectric constant, small dielectric loss, and remain stable at high frequencies. These characteristics make it a preferred material in high-frequency and high-power electronic equipment, such as high-frequency circuit substrates, power module packaging, etc.

3、Good thermal expansion matching

The thermal expansion coefficient of aluminum nitride ceramics substrate is about 4.5×10^-6/K, which is very close to semiconductor materials such as silicon (Si) and gallium arsenide (GaAs). This makes aluminum nitride ceramics an ideal substrate material for semiconductor devices, helping to reduce thermal stress and improve device reliability and stability.

Based on the advantages of ceramic substrates such as good thermal conductivity, heat resistance, insulation and low thermal expansion coefficient, in addition to battery systems, ceramic substrates are widely used in power electronic device packaging. At present, ceramic substrates are mainly used in IGBT, LD device packaging, LED packaging, chip packaging modules, etc.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, boron nitride , aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.