Ceramic Substrate Series - Differences Between Alumina Ceramic Substrates and Aluminum Nitride Ceramic Substrates

1、Introduction to Alumina Ceramic Substrates and Aluminum Nitride Substrates

In the semiconductor circuit industry, ceramic substrates are one of the main materials for circuit boards. Common ceramic substrates include alumina ceramic substrates, aluminum nitride ceramic substrates, and silicon nitride ceramic substrates. Alumina ceramic substrates and aluminum nitride ceramic substrates have different properties and applications due to their different materials.

Alumina ceramic substrates are composed of alumina ceramic material. Due to higher production efficiency and lower cost in the manufacturing process, alumina ceramic substrates are widely used in the semiconductor industry. Aluminum nitride ceramic substrates, on the other hand, are made of aluminum nitride single crystal material. Compared to alumina ceramic substrates, aluminum nitride has higher thermal conductivity and mechanical strength but is also more expensive. Therefore, in applications requiring high-performance, aluminum nitride ceramic substrates are a superior choice.

2、Comparison between Alumina Ceramic Substrates and Aluminum Nitride Ceramic Substrates

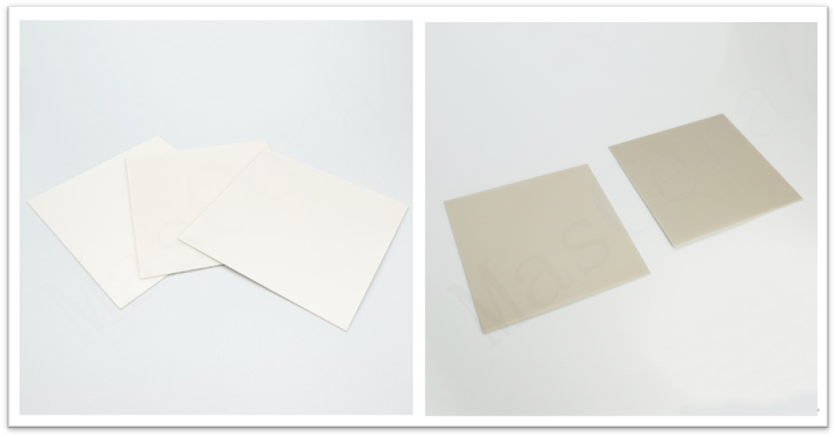

(1) Visual Comparison

Alumina ceramic substrates typically appear white, while aluminum nitride ceramic substrates are grayish-white.

(2) Performance Comparison

.Thermal Conductivity

Due to its high thermal conductivity, aluminum nitride ceramic substrates can better dissipate heat, making circuit boards more stable under high-temperature conditions. In contrast, alumina ceramic substrates have lower thermal conductivity, resulting in inferior performance under high temperatures compared to aluminum nitride ceramic substrates.

.Mechanical Strength

During manufacturing, aluminum nitride ceramic substrates require production under higher temperature and pressure. As a result, aluminum nitride ceramic substrates possess higher mechanical strength and hardness, making them less susceptible to damage or fracture compared to alumina ceramic substrates, which have lower mechanical strength and require more careful handling.

.Electrical Insulation

Electrical insulation performance is crucial in the manufacturing of circuit boards. Aluminum nitride ceramic substrates exhibit higher electrical insulation performance, allowing them to withstand higher voltages. In contrast, alumina ceramic substrates have lower electrical insulation performance and are only suitable for low-voltage circuit boards.

(3) Application Comparison

In the semiconductor industry, both alumina ceramic substrates and aluminum nitride ceramic substrates are important material choices. Alumina ceramic substrates offer higher production efficiency and lower cost in the manufacturing process, suitable for low-voltage circuit boards. On the other hand, aluminum nitride ceramic substrates, due to their high thermal conductivity and mechanical strength, are a better choice for circuit boards requiring high-performance.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.