Everything you need to know about alumina ceramic

Advantages of Alumina Ceramics

(1) High mechanical strength: the flexural strength of alumina ceramic can reach 300MPa,and the strength can be maintained up to 900 ℃

(2) High resistivity: alumina ceramic has good electrical insulation, room temperature resistivity is 1014Ω·cm, dielectric strength is not less than 15kV/mm

(3) High hardness: Mohs hardness is 9

(4) High melting point and good anti-corrosion: melting point of alumina ceramic is 2050 ℃, it can resist the erosion of molten metals such as Be, Sr, Ni, Al, V, Ta, Mn, Fe, Co, etc. It also has high resistance to corrosion by NaOH, glass and slag. It does not react with Si, P, Sb and Bi in an inert atmosphere.

(5) Excellent chemical stability: many composite sulfides, phosphides, arsenides, chlorides, nitrides, bromides, iodides, oxides, and sulfuric acid, hydrochloric acid, nitric acid, and hydrofluoric acid do not react with alumina ceramic.

(6) Optical properties: alumina ceramic can be made into light-transmitting materials (transparent Al2O3 porcelain)

(7) Ionic conductivity

Disadvantages of alumina ceramics

Alumina ceramics have low fracture toughness, poor thermal shock resistance, and cannot withstand rapid changes in temperature. It has low impact resistance, is easily broken, and cannot withstand high pressure shocks. At the same time, because of its low brittleness, its subsequent processing ability is very weak, which is not conducive to recycling, and can basically only be used once.

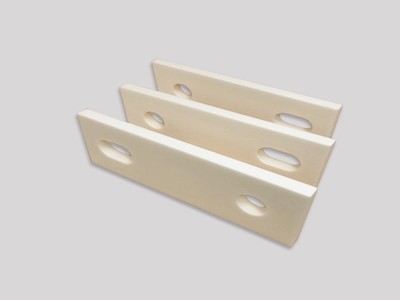

Application fields of alumina ceramics

In the machinery industry, alumina ceramics are widely used in knives, grinding wheels, bearings, valves and other fields due to their high hardness and wear resistance;

In the chemical industry, alumina ceramics are widely used as chemical filler balls, inorganic microfiltration membranes, corrosion-resistant coatings, etc. because they will not be compressed under high strength and high pressure, can resist the erosion of organic solvents and chemical raw materials,

In the medical industry, alumina ceramics have excellent biocompatibility and wear resistance, and are important materials for the manufacture of artificial bones, artificial joints, and artificial teeth;

In the electronics industry, the high resistance, high temperature resistance and high voltage resistance of alumina ceramics make it widely used in ceramic substrates, electrical insulating porcelain parts, transparent ceramics and other fields.

Alumina ceramics is one of the most researched and widely used materials among technical ceramics. In addition to the above applications, it is also widely used in other high-tech fields, such as aerospace, semiconductor and other fields .