How strong is alumina ceramic?

Alumina ceramic (al2o3 ceramic) is an industrial ceramic material with high hardness, high wear resistance and high mechanical strength. Its Rockwell hardness is HRA80-90, its hardness is second only to diamond, and its wear resistance far exceeds that of wear-resistant steel and stainless steel. . As determined by the Institute of Powder Metallurgy of Central South University, its wear resistance is equivalent to 266 times that of manganese steel and 171.5 times that of high-chromium cast iron. High temperature sintered al2o3 ceramic products can only be machined using a diamond grinding process. Under the same working conditions, the service life of the equipment can be extended by at least ten times.

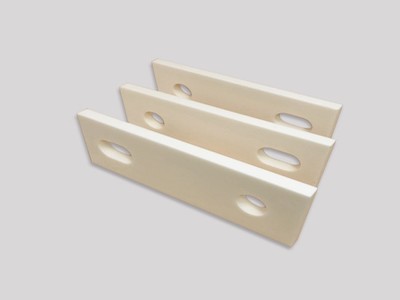

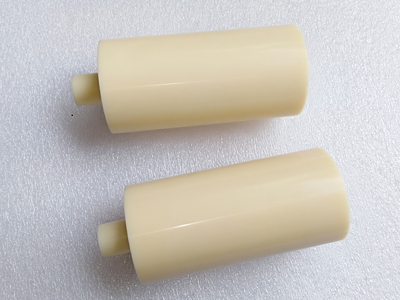

Utilizing its excellent hardness, strength and wear resistance, al2o3 ceramics have been widely used in medical, mechanical, environmental engineering, petroleum, chemical, textile, daily use and other industries. Specific products include ceramic linings or ceramic tubes for wear-resistant pipes, grinding media for fine grinding purposes, ceramic valve cores for faucets, ceramic textile ceramic parts, ceramic linings for ball valves, ceramic cylinder liners for mud pumps, ceramic mechanical seal rings, ceramic plungers, etc. The use of al2o3 ceramic can greatly improve the performance and service life of supporting products, reduce the frequency of replacement, and increase economic benefits.

Alumina ceramics also have good acid and alkali corrosion resistance and oxidation resistance, and will not rust or be corroded by acid and alkali; in addition, the maximum service temperature of alumina ceramics reaches 1750 ° C.

Among all industrial ceramic materials, alumina ceramics are relatively low-cost materials. According to the needs of use, it can be formed or processed into the required size and shape, and can achieve high dimensional accuracy and surface finish.