Key Applications of Boron Nitride Ceramic in Electric Propulsion Technology and Plasma Thrusters

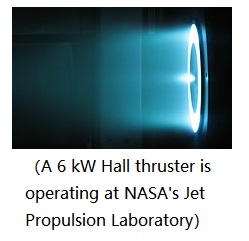

Propulsion technology in space exploration has always faced significant challenges. Traditional chemical propellants require carrying large  amounts of fuel, which increases costs and limits spacecraft mission capabilities. To overcome these limitations, electric propulsion technology has emerged as a more efficient alternative. Among various electric propulsion methods, the Hall thruster—a type of plasma thruster—utilizes a strong electric field to accelerate ions for precise attitude control and orbit raising. For reliable and efficient electric propulsion technology, selecting the right materials for critical components is essential.

amounts of fuel, which increases costs and limits spacecraft mission capabilities. To overcome these limitations, electric propulsion technology has emerged as a more efficient alternative. Among various electric propulsion methods, the Hall thruster—a type of plasma thruster—utilizes a strong electric field to accelerate ions for precise attitude control and orbit raising. For reliable and efficient electric propulsion technology, selecting the right materials for critical components is essential.

Boron Nitride Ceramic: A Key Material for Hall Thrusters

In the realm of advanced ceramics, Boron Nitride Ceramic plays a crucial role due to its exceptional properties, making it an ideal material for electric propulsion technology and space exploration applications. As a structural material in Hall thrusters and plasma propulsion systems, it provides multiple advantages:

1. High-Temperature Resistance

One of the most significant attributes of Boron Nitride Ceramic for Space Exploration is its exceptional high-temperature resistance. The material possesses a high melting point and a low coefficient of thermal expansion, ensuring structural stability under extreme temperatures. This property minimizes deformation or cracking in high-temperature plasma environments, enabling consistent and reliable thrust generation in electric propulsion systems.

2. Superior Electrical Insulation

Boron Nitride Ceramic is an excellent electrical insulator, preventing unwanted current conduction in Hall thrusters. The ionization and acceleration processes in plasma thrusters require materials with high electrical insulation to prevent current leakage and ensure system stability. By using Boron Nitride Ceramic, electric propulsion systems maintain optimal efficiency and reliability in the vacuum of space.

3.Exceptional Corrosion and Plasma Erosion Resistance

Space environments expose materials to ion sputtering and chemical corrosion. Boron Nitride Ceramic for Space Exploration offers remarkable resistance to these harsh conditions, preventing degradation caused by prolonged exposure to ionized gases and extreme operational environments. This durability significantly extends the service life of electric propulsion technology components, reducing maintenance requirements and operational risks.

Advancing Space Exploration with Boron Nitride Ceramic

The use of Boron Nitride Ceramic in electric propulsion technology is essential for the performance and longevity of Hall thrusters and other plasma-based propulsion systems. Its superior high-temperature resistance, outstanding electrical insulation, and excellent corrosion resistance make it a preferred material for space exploration applications.

As advanced ceramics continue to evolve, Boron Nitride Ceramic for Space Exploration will play an increasingly important role in enabling extended mission durations, improving spacecraft efficiency, and supporting deep-space exploration. With its critical properties, Boron Nitride Ceramic ensures a reliable and efficient propulsion system, driving innovation in electric propulsion technology and expanding the frontiers of human space exploration.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.