Ceramic Parts Specialist ∣ Industrial Technical Ceramics

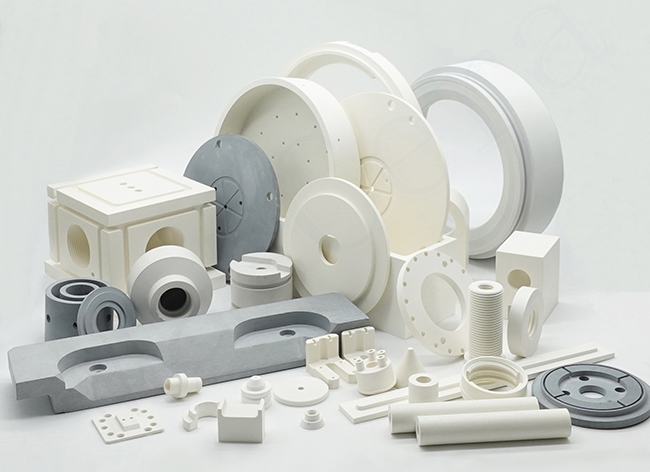

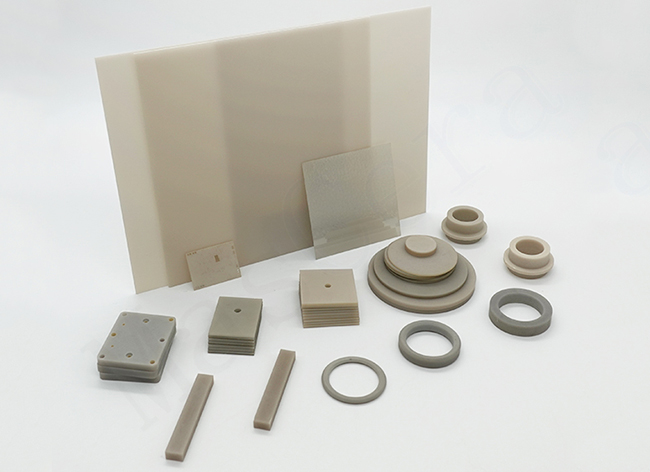

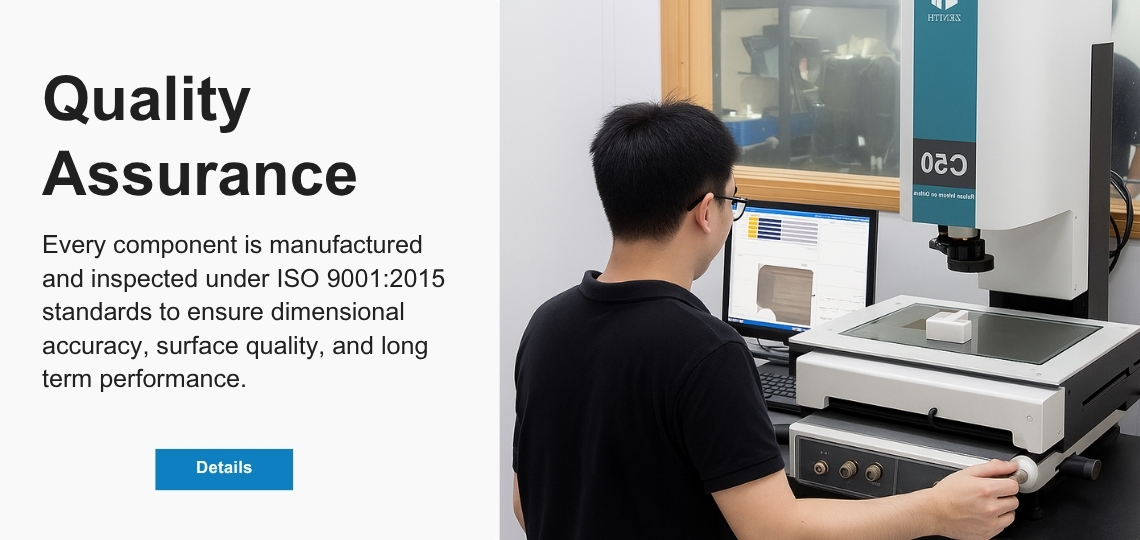

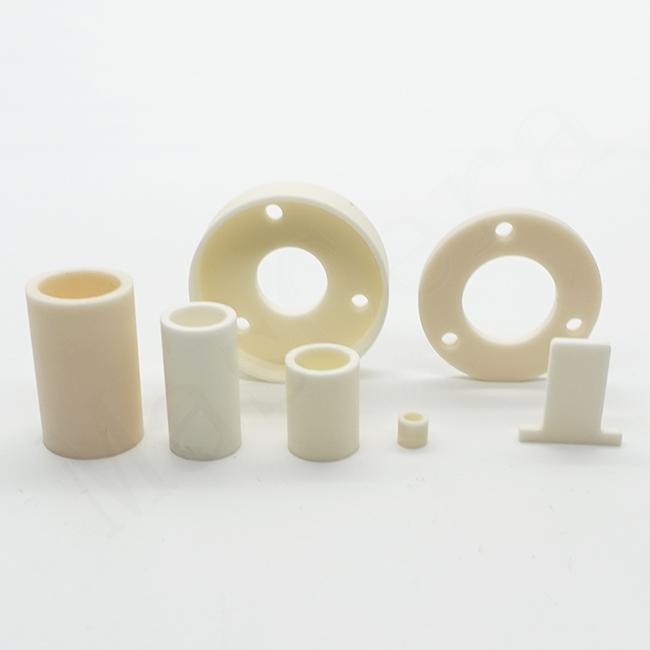

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.

-

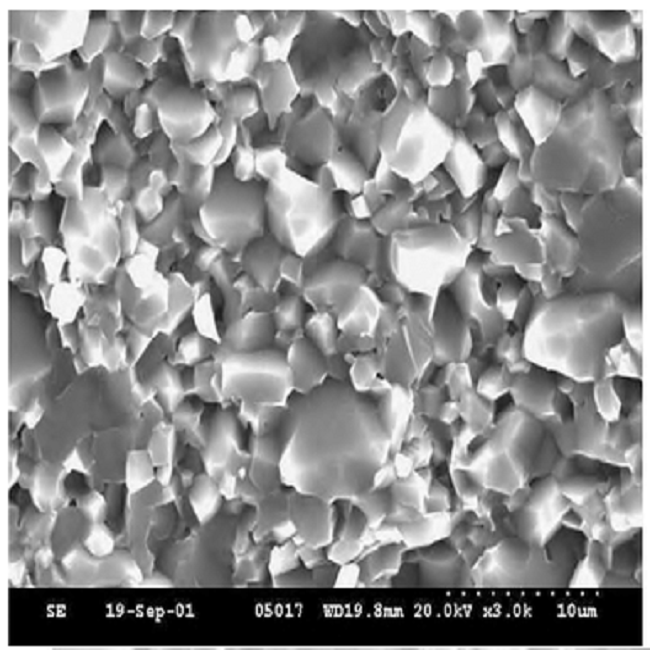

Alumina ceramics is one of the most researched and widely used materials among technical ceramics.

13-07-2022 -

Learn how to select the right alumina ceramic grade based on application, geometry, and manufacturing process. A practical guide with part-specific recommendations.

14-01-2026 -

Explore the differences between alumina ceramic grades (95%–99.8%). Learn how aluminum oxide purity affects electrical insulation, thermal behavior, and industrial applications.

14-01-2026 -

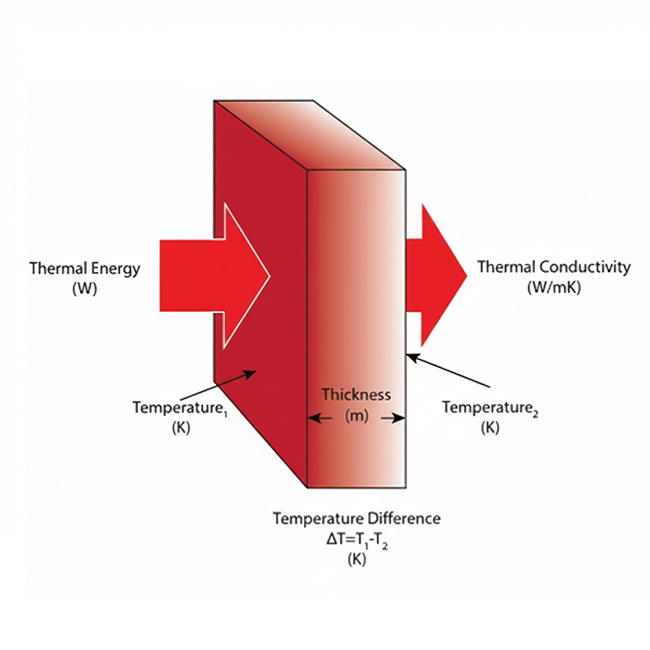

Thermal conductivity is one of the most important physical characteristics of alumina ceramic and a key factor in its widespread use across electronic, electrical, and high-temperature industrial applications.

07-01-2026

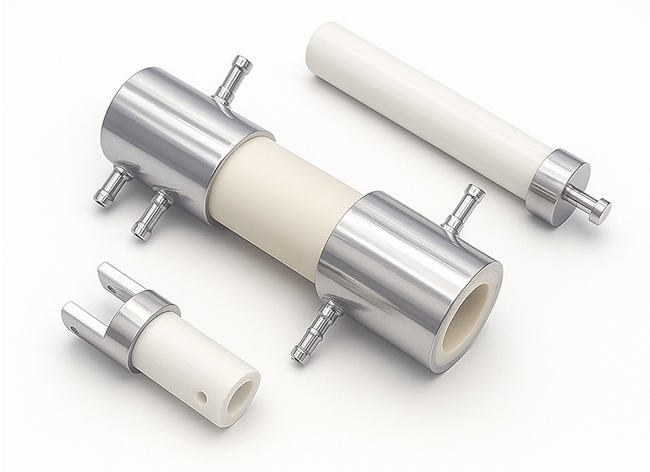

Ceramic Pump

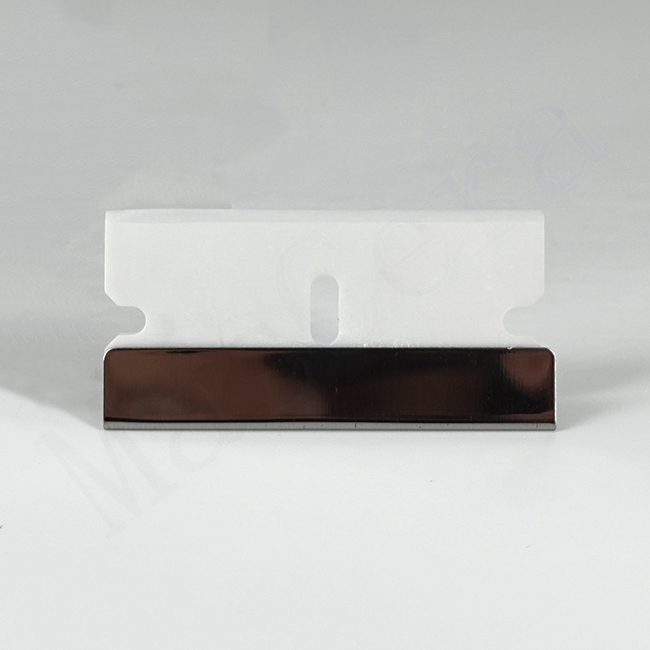

Ceramic Blade

Zirconia Ceramic Bearing Balls

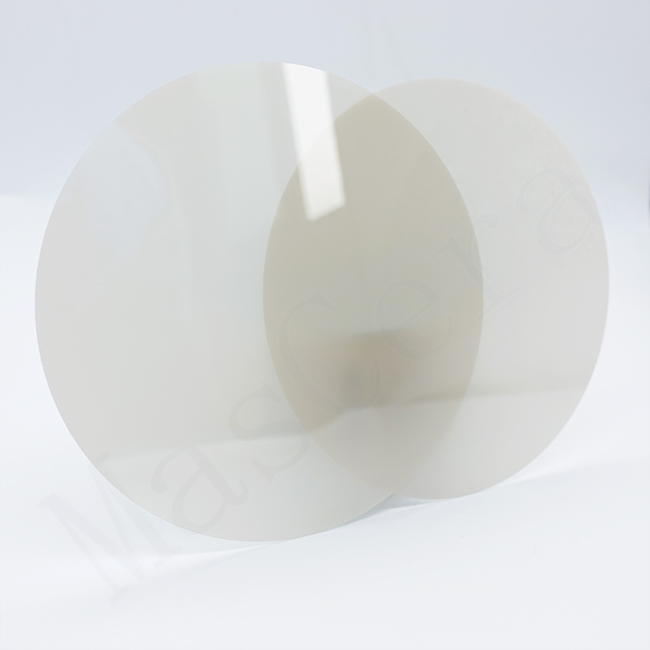

Alumina Ceramic Plate

Silicon Nitride Substrate

Aluminum Nitride Ceramic

Pyrolytic Boron Nitride Crucible

Boron Nitride Tube

Boron Nitride Rod

Boron Nitride Ceramic Thermal Conductivity

Ceramic Pin

Ceramic Valve Seat

Ceramic Thermocouple Insulators

Ceramic Sheath

Alumina Furnace Tube

Thermocouple Ceramic Tube

Ceramic Replacement Blades

Aln Ceramic Sheet

Ceramic Sheet

Aln Substrate