Alumina Ceramic End Effectors for Semiconductor Wafer Handling

- MSJ/AL-013

- Alumina Ceramic

- Customized

- 5 pcs per type

- Semiconductor Industry

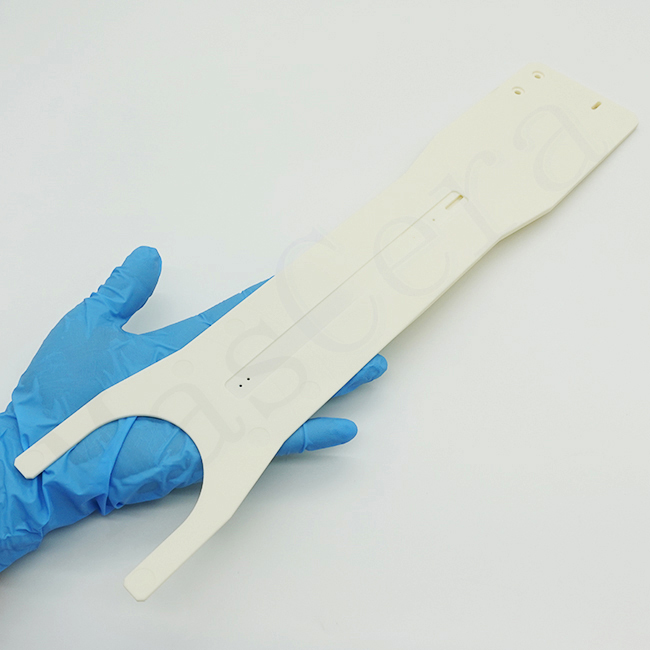

Alumina ceramic end effector produced by Mascera, used as the robotic hand for handling and moving semiconductor wafers. It features precise dimensions and thermal stability, while its smooth and abrasion-resistant surface ensures no particulate contamination during wafer handling.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Detail

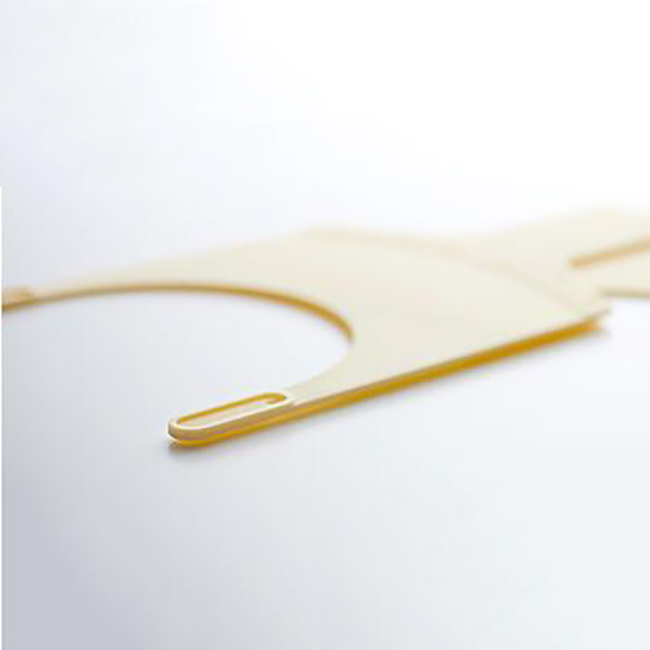

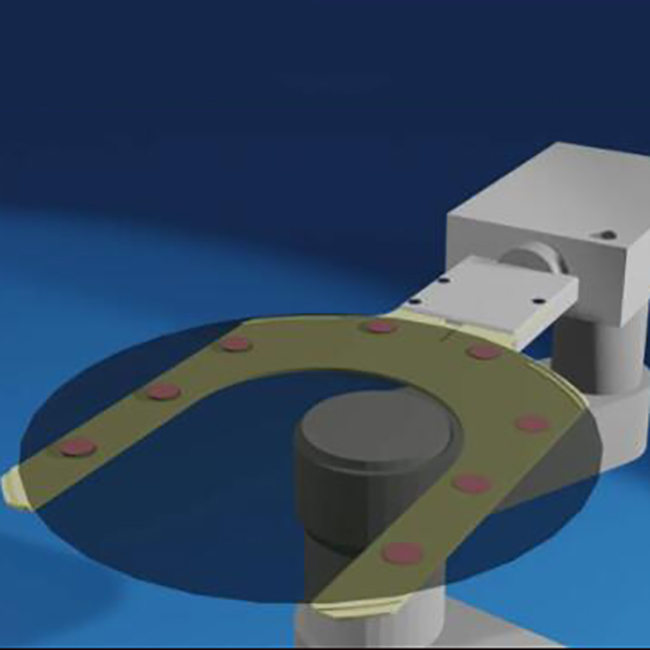

Wafer handling end effectors are installed on wafer handling robots and are responsible for transporting silicon wafers to designated positions. The surface of the end effector comes into direct contact with the wafers. Therefore, the end effector must have precise dimensions and thermal stability, as well as a smooth, abrasion-resistant surface to ensure that no particulate contamination occurs during wafer handling.

Due to the properties of alumina ceramics, such as high-temperature resistance, wear resistance, corrosion resistance, and low friction coefficient, with a maximum operating temperature of up to 1750°C, they exhibit excellent thermal stability and superior mechanical, electrical, and thermal properties. These characteristics make them highly suitable for high-quality components and ensure that the performance requirements of wafer handling end effectors are met.

Mascera's ceramic end effectors are made from high-purity alumina powder through isostatic pressing, high-temperature sintering, and precision machining, offering excellent surface finish and dimensional accuracy to meet the customization needs of users.

Product Features

High hardness and wear resistance

Excellent corrosion resistance

Good insulation properties even at high temperatures

Excellent heat resistance

Superior mechanical strength

Material Data Sheet

Material | Unit | 99.5% Al2O3 | 99.8% Al2O3 |

Purity | % | 99.5 | 99.8 |

Color | --- | Ivory | Ivory |

Density | g/cm3 | 3.90 | 3.92 |

Water Absorption | % | 0 | 0 |

Moh's Hardness | --- | 9 | 9 |

HV Hardness | --- | 1750 | 1800 |

Flexural Strength @25℃ | Mpa | 375 | 390 |

Fracture Toughness | Mpa.M1/2 | 4 | 4 |

Compressive Strength (25℃) | Mpa | 2450 | 2500 |

Thermal Conductivity @25℃ | W/M.K | 29 | 32 |

Thermal Expansion Coefficient | 10-6mm/℃ | 8 | 8 |

Thermal Shock Resistance | △T(℃) | 180-200 | 180-200 |

Max. Working Temperature | ℃ | 1750 | 1750 |

Dielectric Strength | Kv/Mm | 22 | 22 |

Electrical Resistivity (@25℃) | Ω.Cm | 1014 | 1014 |

Dielectric Constant (@1MHz, 25℃) | --- | 9.7 | 9.8 |

Dielectric Loss (Tan Delta) | --- | 0.0001 | 0.0001 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |