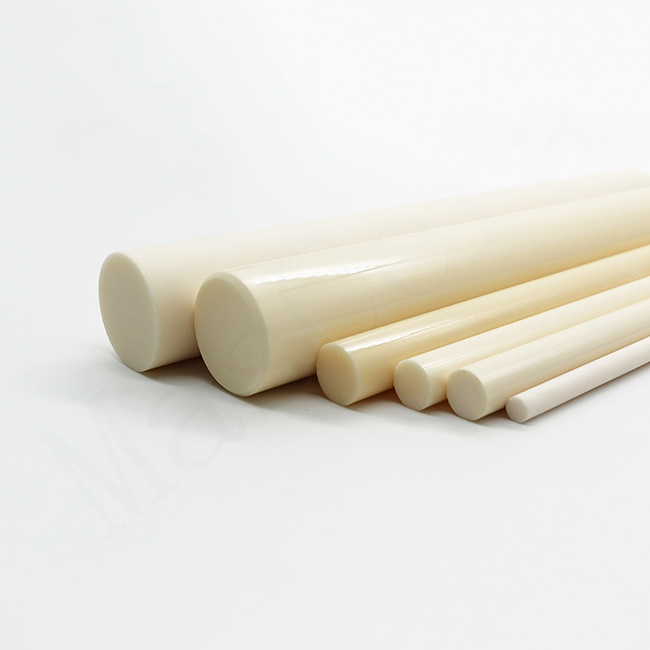

95 99 99.5 Al2O3 Alumina Ceramic Rods

- MSJ/AL-009

- Alumina ceramic

- customized

- 10 pcs per type

- industrial applications

Mascera provides custom-made alumina ceramic rods with varying purities ranging from 95% to 99.8%. The surface finish of these rods can be as-fired, finely ground, or polished, and their geometry can be machined to meet high fitting requirements with tight tolerances. In addition, threads can be machined on both ends of alumina ceramic rods for fastening purposes. Whether it's a small quantity for a prototype or a large quantity for batch production, our services are always available.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Alumina ceramic, also known as Al2O3 ceramic or aluminum oxide ceramic, is a highly versatile technical ceramic material widely used in various industries. It boasts several advantages, including high strength, good dielectric properties, excellent wear resistance, high temperature resistance, and corrosion resistance. It is also one of the hardest and most wear-resistant materials on Earth, requiring diamond tools for machining after sintering.

The fields in which alumina ceramic is applied are extensive and include machinery, electronics, semiconductors, petroleum, chemicals, textiles, and others. Mascera offers tailor-made alumina ceramic rods with varying purities ranging from 95% to 99.8%. The surface finish can be as fired, fine grinding, or polishing, and the geometry can be machined to tight tolerances to meet high fitting requirements. Additionally, threads can be machined on both ends of the alumina ceramic rods for fastening purposes. Whether it's for a small quantity prototype or a large batch production, we are always prepared to provide our services.

Main properties of alumina ceramic rod

Good strength and stiffness

Extremely high hardness (Moh's hardness 9)

Exceptional wear resistance

Good corrosion resistance to acid and alkali

High temperature resistance up to 1750℃

Excellent electrical insulation

Low dielectric constant and dielectric loss

Typical applications of alumina ceamic

Mechanical seal rings

Pump plungers or pistons

Electronic substrates

Ceramic crucibles

Textile eyelets or guides

Ceramic balls/valves/seats for valves

Electrical insulators

Wear resistant nozzles

Ceramic furnace tubes

Ceramic thermocouple protection tubes

Material Data Sheet

| Material | Unit | 95% Al2O3 | 96% Al2O3 | 99% Al2O3 | 99.5% Al2O3 | 99.8% Al2O3 |

|---|---|---|---|---|---|---|

Purity | % | 95 | 96 | 99 | 99.5 | 99.8 |

Color | --- | White/Pink | White | Ivory | Ivory | Ivory |

Density | g/cm3 | 3.65 | 3.72 | 3.85 | 3.90 | 3.92 |

Water Absorption | % | 0 | 0 | 0 | 0 | 0 |

Moh's Hardness | --- | 9 | 9 | 9 | 9 | 9 |

HV Hardness | --- | >1300 | >1300 | 1700 | 1750 | 1800 |

Flexural Strength @25℃ | Mpa | 300 | 300 | 330 | 375 | 390 |

Fracture Toughness | Mpa.M1/2 | 3~4 | 3~4 | 3~4 | 4 | 4 |

Compressive Strength (25℃) | Mpa | 2200 | 2200 | 2350 | 2450 | 2500 |

Thermal Conductivity @25℃ | W/M.K | 18-22 | ≥24 | 27 | 29 | 32 |

Thermal Expansion Coefficient | 10-6mm/℃ | 8 | 8 | 8 | 8 | 8 |

Thermal Shock Resistance | △T(℃) | 220 | 220 | 180-200 | 180-200 | 180-200 |

Max. Working Temperature | ℃ | 1500 | 1500 | 1700 | 1750 | 1750 |

Dielectric Strength | Kv/Mm | 16 | 17.2 | 20 | 22 | 22 |

Electrical Resistivity (@25℃) | Ω.Cm | 1014 | 1014 | 1014 | 1014 | 1014 |

Dielectric Constant (@1MHz, 25℃) | --- | 9 | 9 | 9.7 | 9.7 | 9.8 |

Dielectric Loss (Tan Delta) | --- | 0.0004 | 0.0002 | 0.0002 | 0.0001 | 0.0001 |

Available Shapes of Alumina Ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Machining Ability of Alumina Ceramics

Dimensional accuracy: Up to 0.001mm

Surface roughness: Ra0.05-3.2μm

Concentricity: Up to 0.02mm

Parallelism: Up to 0.01mm

Accuracy of Inner hole Drilling: Up to 0.01mm

Cylindricity: Up to 0.02mm

Thread machining: Minimum internal thread M2

Surface finish: As fired, glazed, grinding, polishing, metallization

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |