Inspection Method Series: Ultrasonic Scanning Microscope SAT Testing

DBC (Direct Bond Copper) ceramic substrate refers to a metalized substrate formed when copper is directly sintered onto aluminum oxide or aluminum nitride ceramics under high-temperature conditions. DBC copper-covered ceramic substrates are favored by users due to their excellent stability, high current-carrying capacity, high electrical insulation, and thermal conductivity. They find wide applications in various fields such as the LED intelligent lighting industry, power electronic devices industry, and even play a significant role in power electronic component carrier plates with high current-carrying capacity and heat dissipation in the new energy vehicle industry's automotive-grade IGBT modules.

In any industry's demands, manufacturers are required to achieve a high brazing rate between the ceramic and copper layers and avoid delamination or bubbles during subsequent usage. The presence of bubbles between copper and ceramics could lead to problems in the strength of the bond at the interface, potentially causing issues like thermal failures in subsequent products. Taking DBC ceramic substrates as an example, the DBC direct bonding copper process utilizes high-temperature heating to combine aluminum oxide (Al₂O₃) and copper (Cu) plates. Despite being an advanced mass production technology in the industry, minor bubbles on the bonding interface are inevitably present. Heat generated during subsequent usage can cause these bubbles to expand, ultimately leading to product failure. Hence, defect detection in ceramic substrates has become an increasingly important aspect for major manufacturers.

In the past, the industry often relied on visual inspection or mechanical property testing. However, manual visual inspection can have certain inaccuracies, machine vision AI inspection cannot identify internal interlayer void defects, and mechanical property testing involves destructive testing, rendering the ceramic substrate unusable after testing.

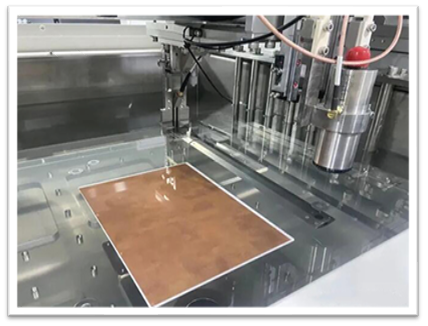

Ultrasonic Scanning Acoustic Microscopy (SAT) combines high precision and non-destructive testing, offering a high sensitivity to gap-related defects such as bubbles and voids within ceramic substrates. It can perform high-precision ultrasound scanning imaging of the bonding interface within DBC ceramic substrates.

The SAT inspection is based on the physical properties of ultrasonic waves, similar to medical ultrasound examinations or sonar detection in submarines. Ultrasonic waves are transmitted into the ceramic substrate's interior through a certain medium. When ultrasonic waves encounter defects such as bubbles, cracks, and delamination, they reflect specific signals. After collecting these reflected waves, computerized image processing is performed to produce visualizations of the interior conditions of the ceramic substrate.

The image accuracy of the ultrasonic scanning microscope inspection equipment has reached a micron level while maintaining high detection efficiency. Additionally, after generating images, automatic calculations of defect areas and void

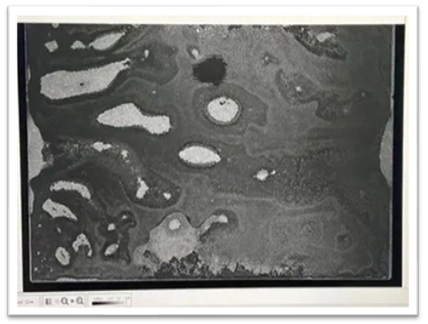

An actual image of DBC ceramic substrate inspection using ultrasonic waves (white areas indicate voids), allowing for intuitive localization of the defect areas.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, silicon carbide, boron nitride, aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.