Development of Silicon Nitride for Advanced Chip Testing Applications

Recently, Kyocera announced the development of a new silicon nitride ceramic material for functional testing of next-generation microchips. This new material boasts enhanced thermal expansion properties and flexural strength, enabling the production of thin silicon nitride plates with extremely narrow spacing between contact probes, which is critical for testing next-generation microchips.

A semiconductor probe card is a precision electronic testing tool used to make contact with various test points on semiconductor chips during wafer-level testing (commonly referred to as "pads"). By establishing contact at these points, the probe card can transmit electrical signals to assess the chip’s functionality, performance, and electrical characteristics. Typically mounted on automatic test equipment (ATE), the probe card is used for preliminary screening before wafer dicing to eliminate defective chips. These probes, installed on silicon nitride guide plates, can consist of metal contacts, spring probes, or MEMS probes. The layout and spacing of these probes must be precisely designed (the distance between probes is often only a few dozen microns, with up to 100,000 probes on a single guide plate) to ensure accurate contact with test points on the wafer. In addition to requiring high mechanical and flexural strength to support the probes, the silicon nitride guide plates’ thermal stability and insulating properties help reduce expansion-induced resistance changes and prevent current leakage, all of which are crucial for accurate testing.

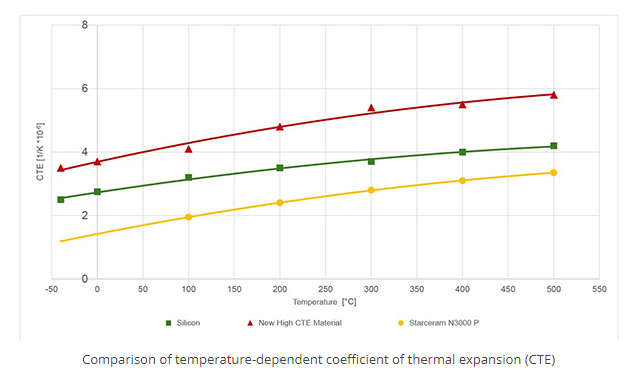

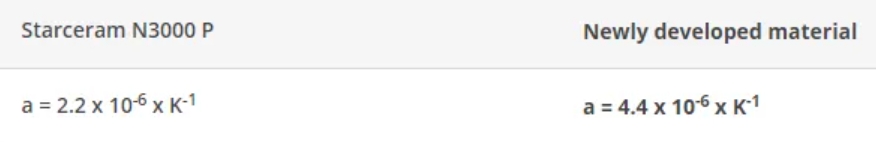

Enhanced Thermal Expansion Coefficient

Kyocera has disclosed that the new silicon nitride has effectively doubled its thermal expansion coefficient at 150°C compared to previous materials and offers a high flexural strength exceeding 800 MPa (megapascals). The combination of the silicon nitride substrate with the probe card enhances efficiency and precision in semiconductor testing, ensuring chip quality and performance.

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a reputable and reliable supplier specializing in manufacturing and sales of technical ceramic parts. We provide custom production and high precision machining for a wide series of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride, boron nitride , aluminum nitride and machinable glass ceramic. Currently, our ceramic parts can be found in many industries like mechanical, chemical, medical, semiconductor, vehicle, electronic, metallurgy etc. Our mission is to provide the best quality ceramic parts for global users and it is a big pleasure to see our ceramic parts work efficiently in customers' specific applications. We can cooperate on both prototype and mass production, welcome to contact us if you have demands.