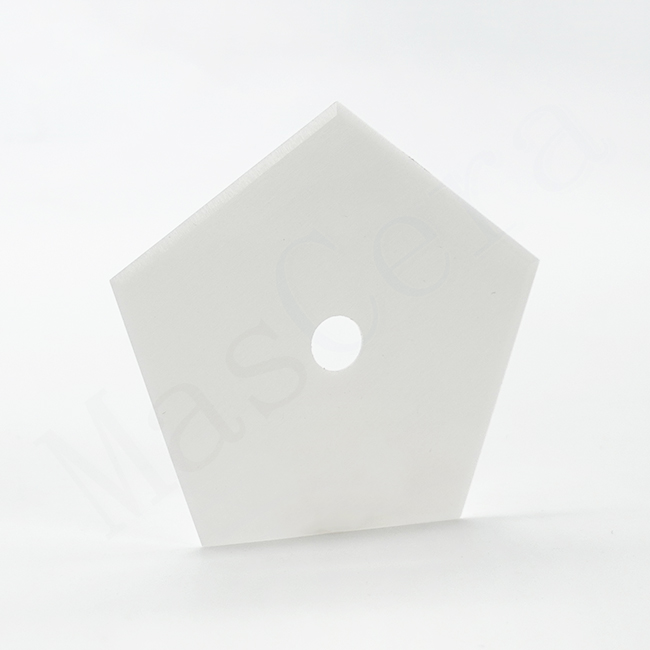

Ceramic Cutting Blade For Empty Hard Capsule Trimming

- MSJ/CCB-004

- zirconia ceramic

- customized size

- 100 pcs per type

- empty hard capsule trimming

Ceramic capsule cutting blades, specifically designed for precise and efficient capsule cutting in industrial and pharmaceutical applications, are typically made from zirconia. These blades provide a superior alternative to traditional metal blades, delivering durable and consistent performance even in demanding environments.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Ceramic blades made from zirconia exhibit extremely high hardness, excellent wear resistance, and outstanding corrosion resistance. Unlike metal blades, zirconia ceramic blades are impervious to rust and maintain a sharp cutting edge over an extended period. These properties significantly reduce replacement frequency and enhance cutting efficiency.

Ceramic capsule cutting blades, specifically designed for precise and efficient capsule cutting in industrial and pharmaceutical applications, are typically made from zirconia. These blades provide a superior alternative to traditional metal blades, delivering durable and consistent performance even in demanding environments.

| Standard Dimensions | 64.5*12.7*1(mm) / 64.5*6.35*1(mm) |

| Optional colors | white / black / brown |

Mascera offers custom manufacturing of zirconia ceramic blades to meet your specific requirements, including custom sizes and thicknesses. We have successfully produced ceramic blades with a thickness as thin as 0.2 mm, and the cutting edge angle can also be tailored to your needs.To ensure short lead times and quick delivery, we maintain stock of some standard ceramic blades. If you are interested in our ceramic blades, please feel free to contact us at any time!

Ceramic blades we are providing:

Ceramic blades for snap off utility knives

Surgical ceramic blade

Ceramic blade for capsule trimming

Ceramic blade for cloth cutting

Ceramic blade for carpet cutting

Ceramic blade for plastic film slitting

Deburring ceramic blade

Comparing to traditional metal cutting blades, ceramic blades have several advantages:

Sharpness of cutting edge will remain 60 times longer than steel blades

Never rust like metal blades

Non-magnetic and non-electrostatic

Good corrosion resistance to acids and alkali

Good electrical insulation

High temperature resistance

Material Data Sheet

| Items | Unit | Value |

|---|---|---|

Materiral | -- | zirconia ceramic |

Color | -- | White |

Density | g/cm3 | 5.95-6.05 |

HRA Hardness | -- | >87 |

Fracture Toughness | Mpa.m1/2 | 7 |

Flexural Strength (@R.T.) | Mpa | 900 |

Compressive Strength (@R.T.) | Mpa | 2200 |

Thermal Conductivity (@R.T.) | W/m.k | 2.2 |

Coefficient of Thermal Expansion (20-1000℃) | 10-6/℃ | 10.3 |

Thermal Shock Resistance | △T(℃) | 280-350 |

Max. Working Temperature (@R.T.) | ℃ | 850 |

Volume Resistivity (@R.T.) | Ω.cm | 1012 |

Dielectric Constant (1MHz, @R.T.) | -- | 26 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Why Choose Us

10+ years experience in technical ceramics manufacturing and R&D

ISO9001:2015 certificated quality control management system

Different types of ceramic materials are provided for your different applications

Products have been exported to 40+ countries and have good reputation from our customers

MOQ is low, both prototype and bulk order will keep high quality

Any of your inquiries or questions will be responded no longer than 24 hours

Rigorous production plan to ensure on-time delivery