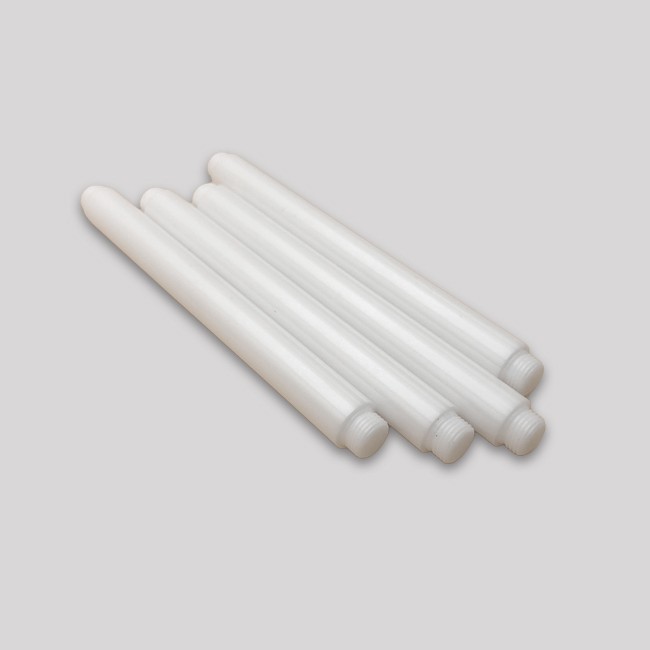

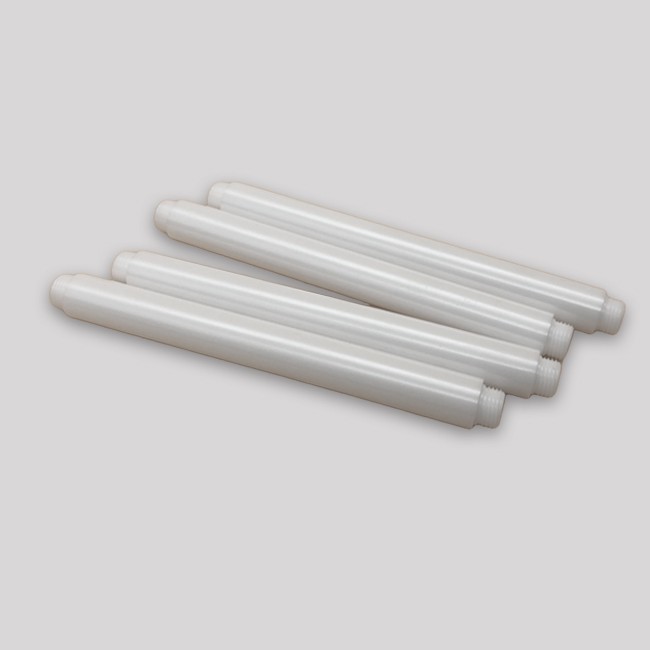

Partially Stabilized Zirconia Ceramic Rod

- MSJ/ZR-005

- zirconia ceramic (Y-PSZ)

- customized

- 10 pcs per type

- industrial applications

Mascera specializes in custom production of zirconia ceramic rods. These rods are crafted from extremely hard zirconia ceramic (ZrO2, Zirconium Oxide) known for its exceptional hardness, reaching up to Moh's grade 8.5, which is closely comparable to diamond (Moh's grade 10). As a result, zirconia ceramic rods can only be machined using diamond machining tools. Our ceramic rods are manufactured using superfine raw powders, ensuring a fully dense structure, and can achieve a mirror-like surface finish through meticulous fine grinding and polishing processes.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Mascera specializes in custom production of zirconia ceramic rods. These rods are crafted from highly durable zirconia ceramic (ZrO2, Zirconium Oxide), known for its extreme hardness. With a hardness rating of up to Moh's grade 8.5, which is close to that of diamond (Moh's grade 10), zirconia ceramic rods require diamond machining tools for precise machining. Our ceramic rods are manufactured using superfine raw powders, resulting in fully dense structures. Through fine grinding and polishing, we can achieve a mirror-like surface finish.

Partially Stabilized Zirconia (PSZ) components are more expensive than alumina and other oxide ceramics, but they offer unique properties such as extremely high fracture toughness, high thermal expansion, high flexural strength (MOR), and low thermal expansion. Due to their high fracture toughness and MOR, PSZ components resist crack propagation, are less brittle, and are capable of holding a sharp edge. PSZ components also act as thermal insulators, and their high thermal expansion makes it easier to join metal to steel, thanks to their low thermal conductivity. Some typical applications of PSZ components include knives, guides, and pump and valve components used in abrasive solutions and slurries.Furthermore, the low thermal coefficient of zirconia ceramic rods enables seamless assembly and compatibility with steel parts.

At Mascera, we offer zirconia ceramic rods in custom sizes and machining specifications. Our production capabilities allow us to achieve high accuracy, with tolerances of up to +/- 0.002mm. Additionally, surfaces can be polished to a roughness of Ra0.1μm. If desired, we can incorporate external threads on both ends of the ceramic rods for convenient fastening purposes.

Types of Zirconia Ceramics

Mascera has two types of zirconia ceramic in our product range, Yttria Partially Stabilized Zirconia (Y-PSZ) and Magnesia Partially Stabilized Zirconia (Mg-PSZ). Pure zirconia ceramic will have transformation of crystal structure when temperature reaches the certain value, the volume changes drastically when the crystal phase changes, and the finished parts after sintering will crack. To provent this problem, stabilizing agent like Yttrium oxide (Y2O3) or Magnesium oxide (MgO) are doped into zirconia ceramic by changing the crystal structure from a monoclinic to stable tetragonal phase.

Both Y-PSZ and Mg-PSZ have excellent mechanical properties such as high hardness, high mechanical strength, good wear resistance and good corrosion resistance in room temperature. The difference is that Mg-PSZ has better strength in mosit and high temperature environment while the mechanical properties of Y-PSZ begin to deteriorate.

Main properties of zirconia ceramic rods

Relatively high fracture toughness among all technical ceramics

High mechanical strength and high hardness

Very good wear resistance

Good resistance to acids and alkalis

Low thermal conductivity – the lowest amount all technical ceramics

can be joint to steel parts because the similar coefficient of thermal expansion

Electrical insulation

Typical applications of zirconia ceramic

Wire forming/drawing dies

Ceramic valve components (balls, seats, liners)

Ceramic pump liners

Mechanical seals

Ceramic cutting blades/knives

Grinding media

Thermal insulation components

Medical and surgical component

Precision ceramic balls for bearings

Material Data Sheet

| Item | Unit | Technical parameters | |

|---|---|---|---|

| Material | -- | Y-PSZ | Mg-PSZ |

| Color | -- | White | Yellow |

| Density | g/cm3 | 5.95-6.05 | 5.70 |

| Hardness(HV 0.5) | -- | 1300 | 1100 |

| Fracture Toughness | Mpa.M1/2 | 7 | 6-7 |

| Flexural Strength (@R.T.) | Mpa | 900 | 500 |

| Compressive Strength (@R.T.) | Mpa | 2200 | 2000 |

| Thermal Conductivity (@R.T.) | W/Mk | 2.2 | 2.2 |

Coefficient Of Thermal Expansion (20-1000℃) | 10-6/℃ | 10.3 | 10.3 |

| Thermal Shock Resistance | △T(℃) | 280-350 | 450 |

Max. Working Temperature (@R.T.) | ℃ | 850 | 2000 |

Available Shapes of Zirconia Ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |