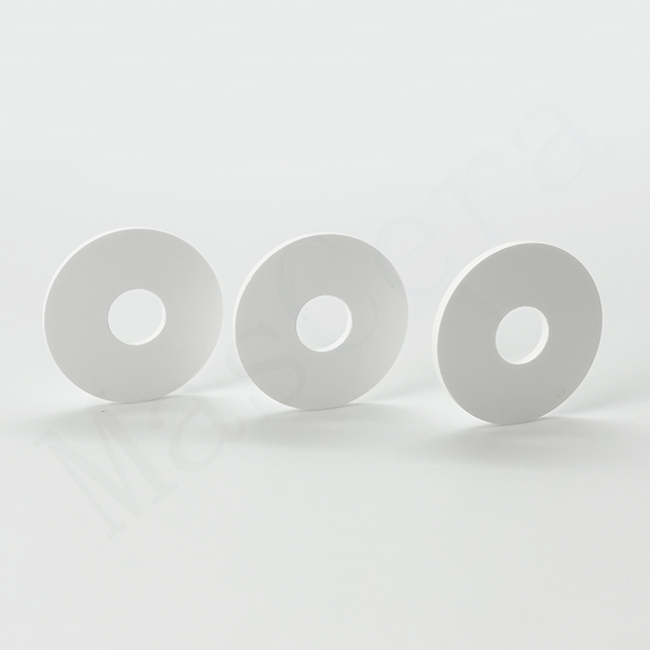

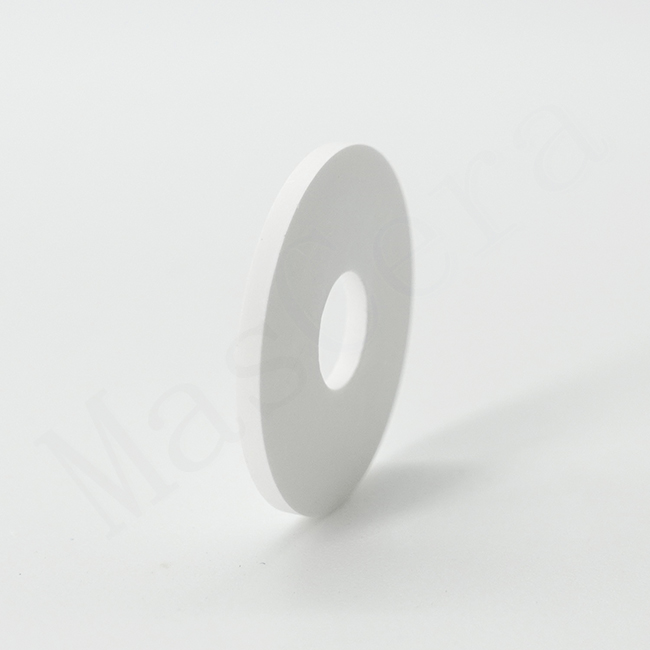

Pbn Pyrolytic Boron Nitride Ceramic Washer

- MSJ/BN-010

- pyrolytic boron nitride (PBN)

- customized

- 10 pcs per type

- industrial applications

Pyrolytic boron nitride is also called as PBN or Pyrolytic BN, it is an advanced ceramic material with excellent properties. It also has hexagonal crystal structure like hot pressed boron nitride ceramic, but is produced in different manufacturing process. PBN ceramic is produced by the method of chemical vapour deposition (CVD), no need to go through the traditional hot pressing sintering process, without adding any sintering agent, the purity is able to reach 99.99%.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Pyrolytic boron nitride, also known as PBN or Pyrolytic BN, is an advanced ceramic material with exceptional properties. Similar to hot-pressed boron nitride ceramic, it possesses a hexagonal crystal structure. However, PBN ceramic is produced using a different manufacturing process known as chemical vapor deposition (CVD), which does not require traditional hot pressing sintering or sintering agents, resulting in a purity level of up to 99.99%. Due to its high purity, outstanding thermal stability, and chemical inertness, PBN ceramics are ideal for use in semiconductor components and vacuum systems. . It is commonly employed in the production of ceramic crucibles for the growth of compound semiconductors (such as GaAs, InP, etc.), crucibles for molecular beam epitaxy, and crucibles for OLEDs, among other applications.

Main properties of PBN ceramic

1. High purity (>99.99%)

2. High density (>2.12g/cm3)

3. No gas is released at high temperature

4. Uniform thickness, good heating consistency

5. Excellent thermal conductivity and thermal shock resistance

6. High interlayer strength, easy to clean and repeated use

7. Chemically inert, does not react with acids, alkalis, salts and organic solvents at high temperatures

Typical applications of pyrolytic boron nitride ceramic

1.Cruciles for in-situ synthesis of GaAs, InP, GaP and other semiconductor single crystals.

2. Crucibles and boats for the synthesis of single crystals or polycrystals of other III-V compounds.

3. MBE crucible for molecular beam epitaxy.

4. PBN/PG composite heater coating for annealing furnace.

5. Insulation parts in high temperature vacuum furnace.

6. Graphite heater insulation coating.

7. High temperature insulated nozzle.

8. MOCVD insulation board.

9. Special-shaped crucible and special-shaped graphite parts coating.

10. Crucible for special metallurgy

Material Data Sheet

| Property | Unit | Technical Value |

|---|---|---|

| Density | g/cm3 | 1.95-2.22 |

| Lattice constant | m | a:2.5x10-10 c:6.8x10-10 |

| Tensile strength | Mpa | 80 |

| Bending strength | Mpa | 243 |

Thermal conductivity (at 200℃) | w/mk | 82.3(a) 2.6(c) |

Thermal conductivity (at 900℃) | w/mk | 55.3(a) 2.8(c) |

| Thermal expansion coefficient | mm/mm/k | 2.0x10-6(a) |

| Dielectric Constant (10GHz) | - | 5.2(a) 3.8(c) |

| Dielectric Strength | Kv/mm | 56 |

| Electrical Resistivity | Ω.cm | 1015 |

| Total Metallic Impurities | ppm | ≤10 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |