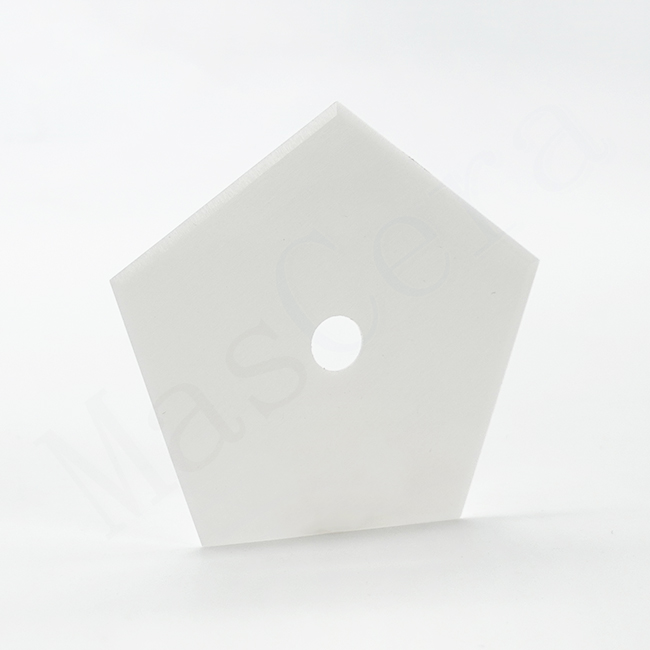

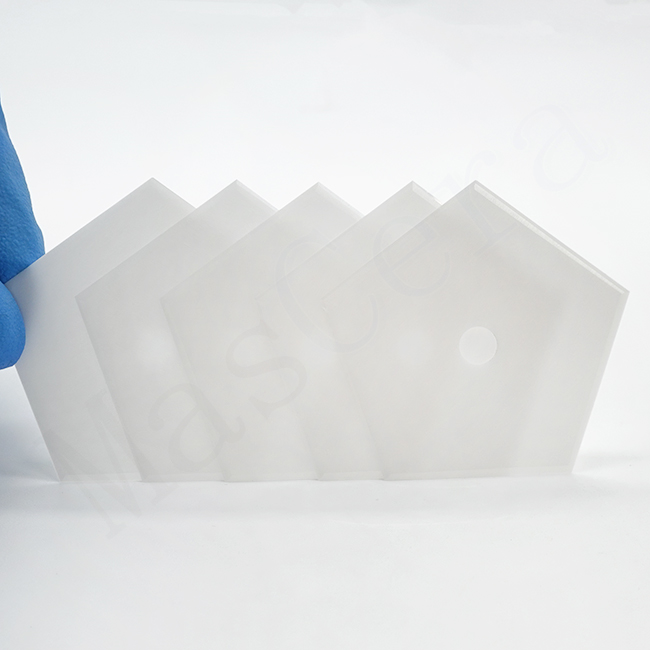

Pentagonal ceramic blades for bigbag weaving machines

- MSJ/CCB-009

- zirconia ceramic

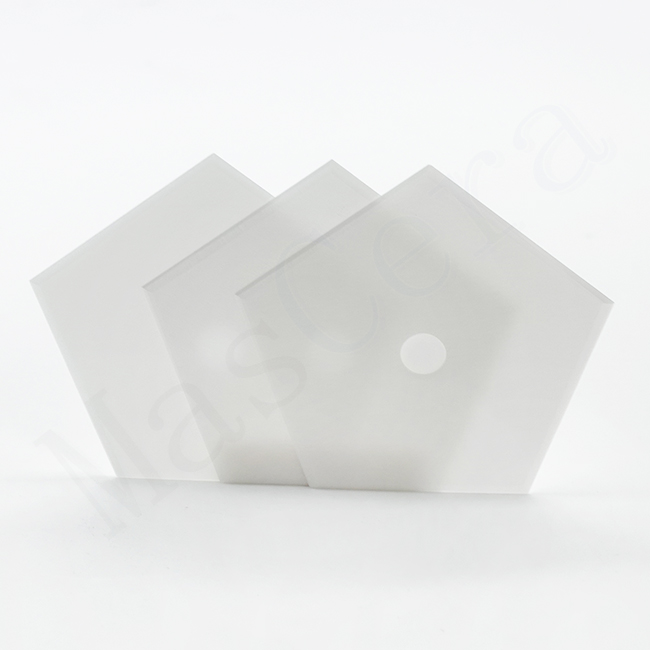

- Customized

- 10 pcs per type

- Utility knives

This is a pentagon-shaped ceramic blade made of zirconia material, designed to maintain a sharp edge for an extended period. It is rust-resistant and durable, making it suitable for cutting textiles. MASCERA can customize the blade size according to customer requirements, allowing the blade to flexibly adapt to your fixtures.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

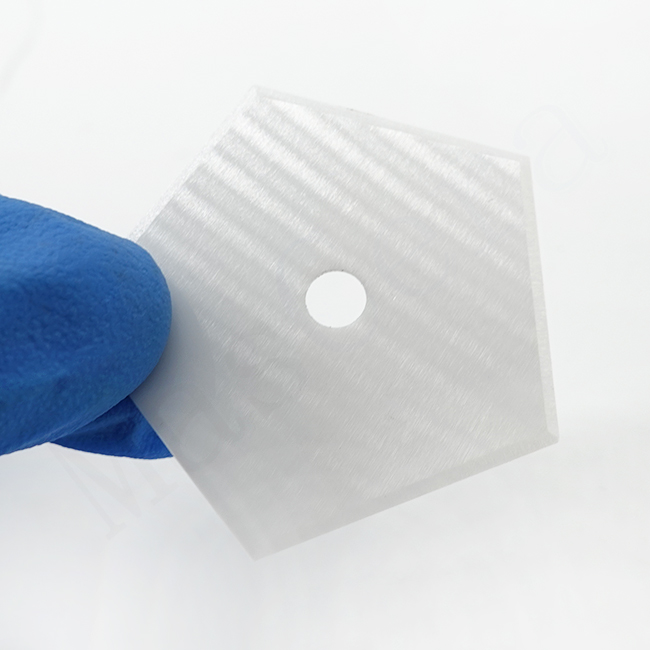

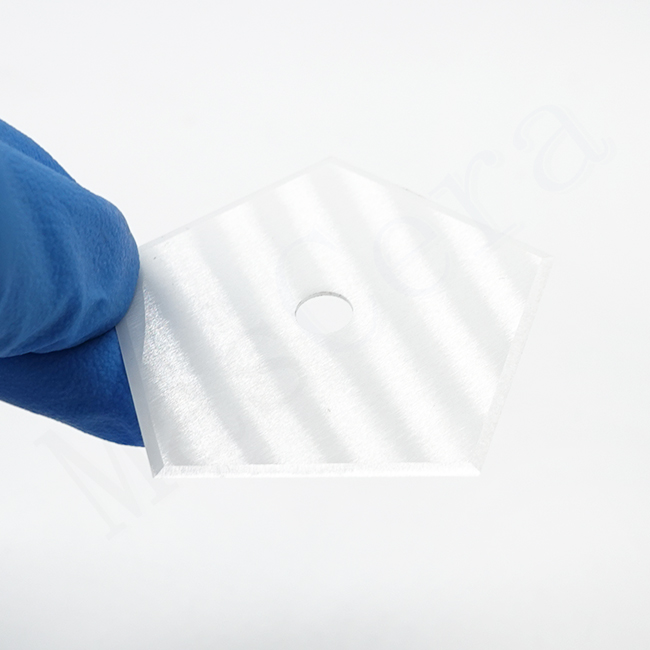

Product detail

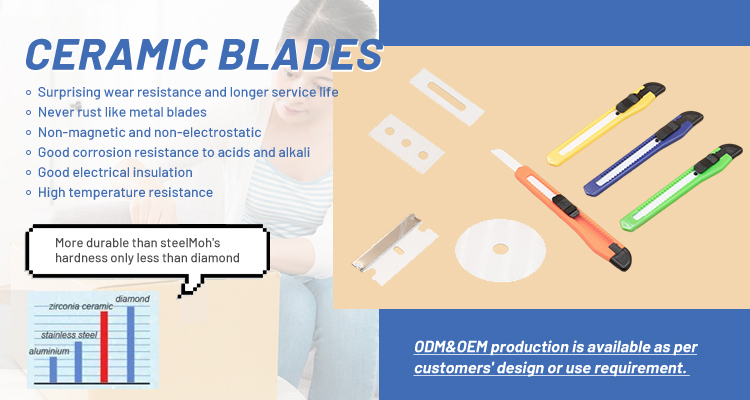

The ceramic blades produced by MASCERA are typically made by dry pressing zirconia powder and sintering through solid-state sintering. The final blades are sharpened by grinding the edges with diamond. Zirconia material possesses a low coefficient of friction, is non-magnetic, and exhibits resistance to acids. Depending on the application, it shows superior performance compared to tungsten carbide, with even lower ductility than tungsten carbide, especially in high humidity or when in contact with chemical substances.

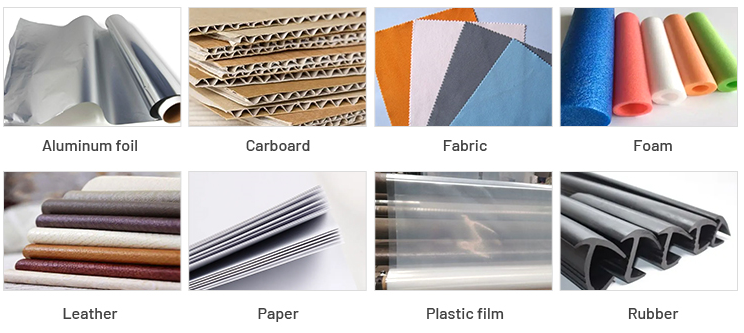

Ceramic blades, with their minimal cutting resistance, maximum wear resistance, and sharp edges, are widely used in industries such as paper and paper product processing, tape products, film, rubber, aluminum foil, chemical fiber, non-woven fabrics, composite packaging materials, cigarettes, leather, printing, packaging, food, textile, and clothing.

Key Features

Zirconia Ceramic Blade

The blade is crafted from high-quality zirconia ceramic, renowned for its remarkable hardness and wear resistance. It maintains sharpness and durability, ensuring consistent and stable use over time.

Extended Lifespan

Compared to traditional metal blades, zirconia ceramic blades have an extended lifespan. Their wear resistance and durability make them an ideal choice for prolonged use, reducing the frequency and cost of blade replacements.

Exceptional Sharpness

The zirconia ceramic blade excels in cutting ability, effortlessly slicing through materials like paper, plastic, and aluminum foil. Its smoothness and precision during cutting are truly impressive.

Blade Breaking Line Function

This utility knife features a unique blade design with a breaking line function. When the blade becomes dull, you can conveniently break off the worn portion along the breaking line, exposing a sharper section and extending the blade's usability.

Replaceable Blades

Equipped with a replaceable blade system, the utility knife allows quick and hassle-free blade replacements. No longer do you need to go through the hassle of sharpening blades; simply replace them for continuous high-performance cutting.

Application

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Company Introducton

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a China supplier which specialized in custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to 40 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

With expertise of material properties and machining technique, Mascera is able to give our customers the most valuable solutions for their specific applications and cooperate from prototype development to mass production. It is our honor that our technical ceramics components are used by some research institutes and high-tech enterprises, and make small contribution for technology innovation.