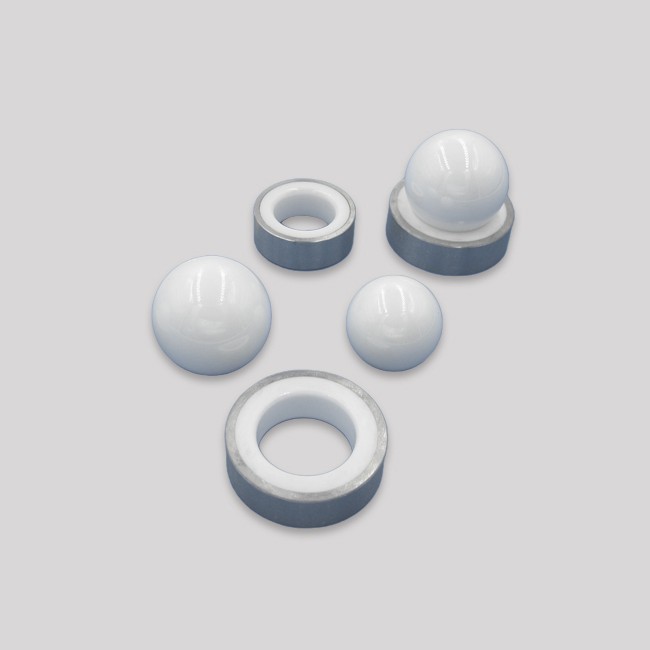

Zirconia Ceramic Valves For Sucker Rod Pump

- MSJ/ZR-009

- zirconia ceramic (Y-PSZ)

- customized

- 10 pcs per type

- sucker rod pump

Because of excellent properties in mechanical and chemical aspects, zirconia ceramic (zro2 / zirconium oxide) was found a good application as high sealing performance ceramic valves for sucker rod pumps. The using of zirconia ceramic has greatly improved the working life of metal valves, zirconia ceramic valves have higher strength, better wear resistance and better corrosion resistance, effectively reducing the risk for contamination during using period. Zirconia ceramic valves are durable enough and need less maintenance time and cost, will bring better economic benenits for users.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Because of excellent properties in mechanical and chemical aspects, zirconia ceramic (zro2 / zirconium oxide) was found a good application as high sealing performance ceramic valves for sucker rod pumps. The using of zirconia ceramic has greatly improved the working life of metal valves, zirconia ceramic valves have higher strength, better wear resistance and better corrosion resistance, effectively reducing the risk for contamination during using period. Zirconia ceramic valves are durable enough and need less maintenance time and cost, will bring better economic benenits for users.

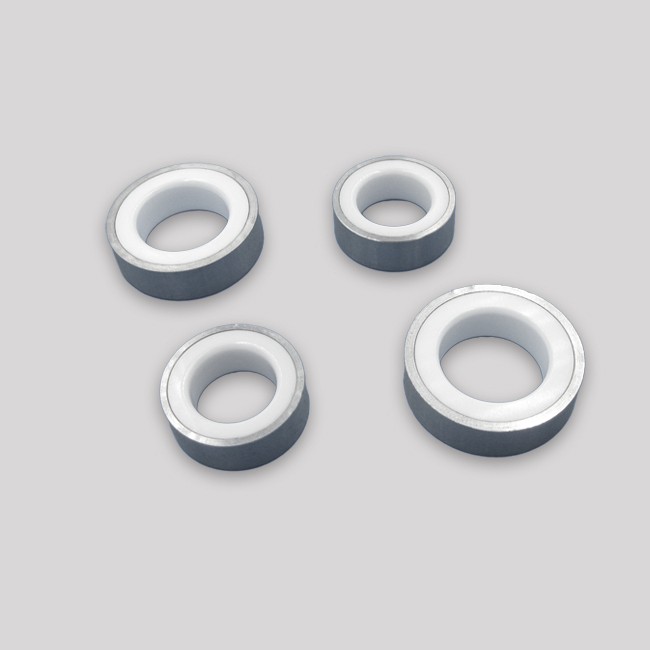

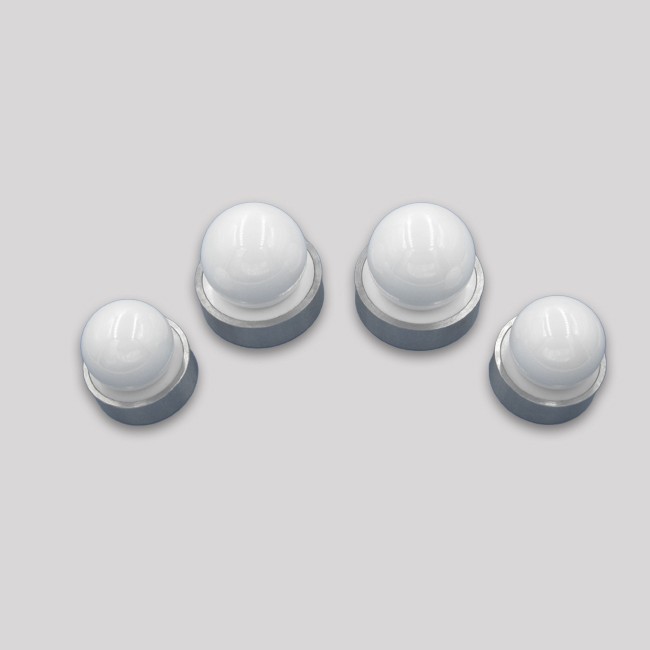

Mascera is specialist in production of ceramic valve balls and ceramic valve seats, the ceramic valve balls are fully dense and have superfine roundness, the contact surface between valve balls and valve seats are highly polished and tighly sealed after our “matched grinding”process, a standardized leakage test will be performed by our quality inspection department to guarantee that leakage will not happen during using.

Main feature of zirconia ceramic valves

Much better corrosion resistance than metal materials

High mechanical strength and toughness

Good resistance to acids and alkalis

Zero leakage because of the perfect sealing between balls and seats

can be joint to steel parts because the similar coefficient of thermal expansion

High temperature resistance

Typical applications of zirconia ceramic

Wire forming/drawing dies

Ceramic valve components (balls, seats, liners)

Ceramic pump liners

Mechanical seals

Ceramic cutting blades/knives

Grinding media

Thermal insulation components

Medical and surgical component

Precision ceramic balls for bearings

Material Data Sheet

| Item | Unit | Technical parameters |

|---|---|---|

| Material | -- | Y-PSZ |

| Color | -- | White |

| Density | g/cm3 | 5.95-6.05 |

| Hardness(HV 0.5) | -- | 1300 |

| Fracture Toughness | Mpa.M1/2 | 7 |

| Flexural Strength (@R.T.) | Mpa | 900 |

| Compressive Strength (@R.T.) | Mpa | 2200 |

| Thermal Conductivity (@R.T.) | W/Mk | 2.2 |

Coefficient Of Thermal Expansion (20-1000℃) | 10-6/℃ | 10.3 |

| Thermal Shock Resistance | △T(℃) | 280-350 |

Max. Working Temperature (@R.T.) | ℃ | 850 |

Available Shapes of Zirconia Ceramics

Ceramic rod / ceramic pin / ceramic plunger

Ceramic tube / ceramic bushing / ceramic sleeve

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

Ceramic plate / ceramic block

Ceramic ball

Ceramic piston

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |