Aln Aluminum Nitride Ceramic Rod

- MSJ/ALN-004

- aluminum nitride ceramic

- customized

- 10 pcs per type

- industrial applications

Aluminum nitride ceramics, also called as AlN ceramics, have the advantages of high thermal conductivity, good electrical resistance and low density, the coefficient of aluminum nitride ceramics is similar to that of silicon. The excellent properties make aluminum nitride ceramics become an ideal material for applications where good heat spreading capability and good electrical insulation are required.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Aluminum nitride ceramics, also called as AlN ceramics, have the advantages of high thermal conductivity, good electrical resistance and low density, the coefficient of aluminum nitride ceramics is similar to that of silicon. The excellent properties make aluminum nitride ceramics become an ideal material for applications where good heat spreading capability and good electrical insulation are required. Aluminum nitride ceramics have good temperature resistance, they are stable to very high temperatures in inert atmospheres. In air, oxidation will occur on the surface when temperature exceeds 700℃,the oxide layer will protect the material up to 1370℃.

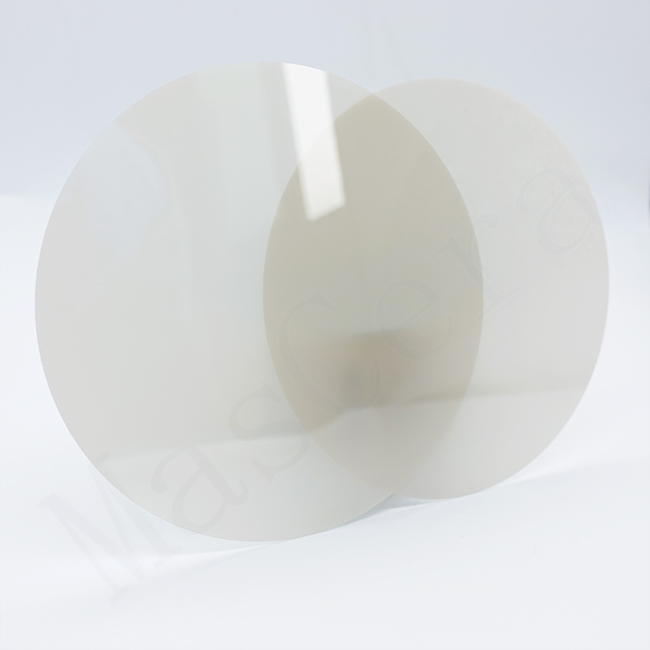

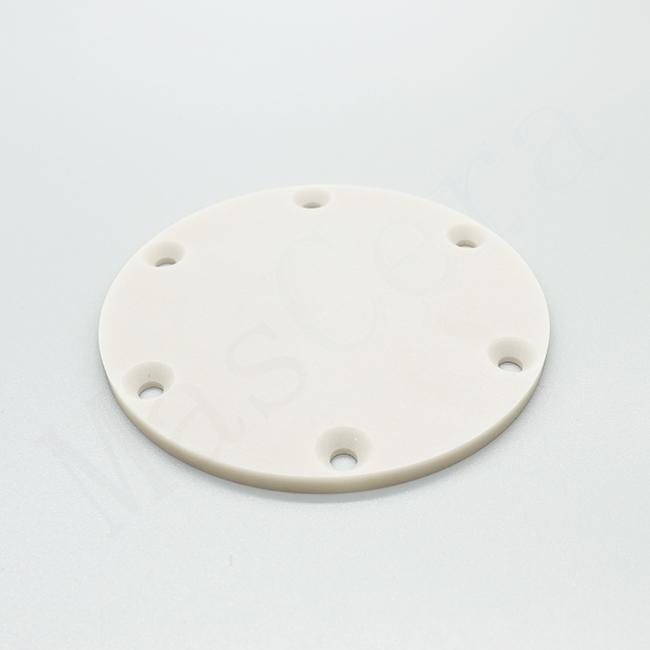

Aluminum nitride rods can be used for applications where high thermal conductivity and good electrical insulation are required. The sizes can be customized according to customer's requirement. Our strong machining ability helps us control aluminum nitride rods in tight tolerance and smooth surface.

Main properties of aluminum nitride rods

High mechanical strength

Good electrical insulation

Low dielectric constant and dielectric loss

Similar thermal expansion with Silicon

High thermal conductivity

Excellent corrosion resistance

Non-toxic

Typical applications of aluminum nitride ceramic

1. Optical communication device application

2. Special refrigerator

3. LED industry

4. Automotive electronic modules

5. High efficiency power module

6. High frequency microwave application

7. Power electronic components

Material Data Sheet

| ITEMS | UNIT | PARAMETER |

|---|---|---|

| Al2O3 Purity | % | 95 |

| Color | ‐ | Light Grey |

| Density | g/cm3 | ≥3.3 |

| Water Absorption | % | 0 |

| Moh’s Hardness | ‐ | 8 |

| Flexural Strength(at 25℃) | Mpa | 365-420 |

| Compressive Strength(at 25℃) | Mpa | 310-320 |

| Thermal Conductivity | W/m.k | ≥170 |

| Coefficient of Thermal Expansion(20~300℃) | 10‐6/℃ | 4.6 |

| Max working temperature | ℃ | 1800 |

| Volume Resistivity | Ω.cm | 1013 |

| Dielectric Constant(1MHz, 25℃) | ‐ | 9 |

| Dielectric Loss(1MHz, 25℃) | ‐ | 3.8 X 10-4 |

| Dielectric Strength | KV/mm | 17 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Company Introducton

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a China supplier which specialized in custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

We have completed production lines for molding, sintering, high precision machining, quality inspection of technical ceramic components. Our products are in conformity with ISO9001:2015 quality management system and we are capable to deliver ceramic components of fully dense, accurate size and surface finish control, prompt lead time.

Since our foundation, Mascera has committed to providing ceramic components of highest quality and has built faithful partnership with our customers. Currently, our products have been exported to 40 countries and widely applied in industries like machinery, automotive, chemistry, medical, energy, electronic, semiconductor, aerospace, telecommunication etc.

With expertise of material properties and machining technique, Mascera is able to give our customers the most valuable solutions for their specific applications and cooperate from prototype development to mass production. It is our honor that our technical ceramics components are used by some research institutes and high-tech enterprises, and make small contribution for technology innovation.