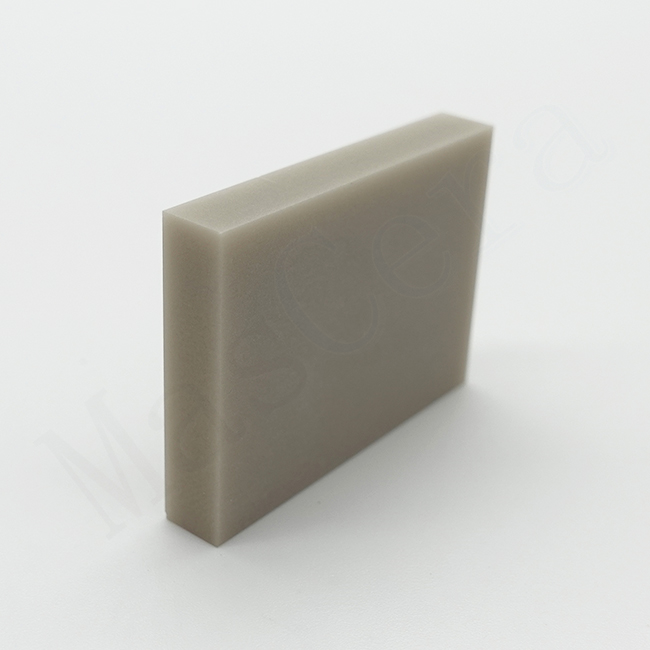

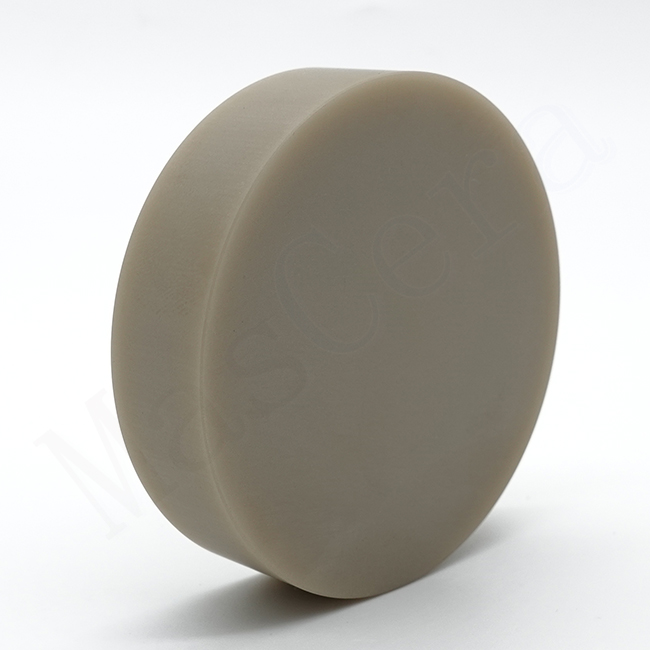

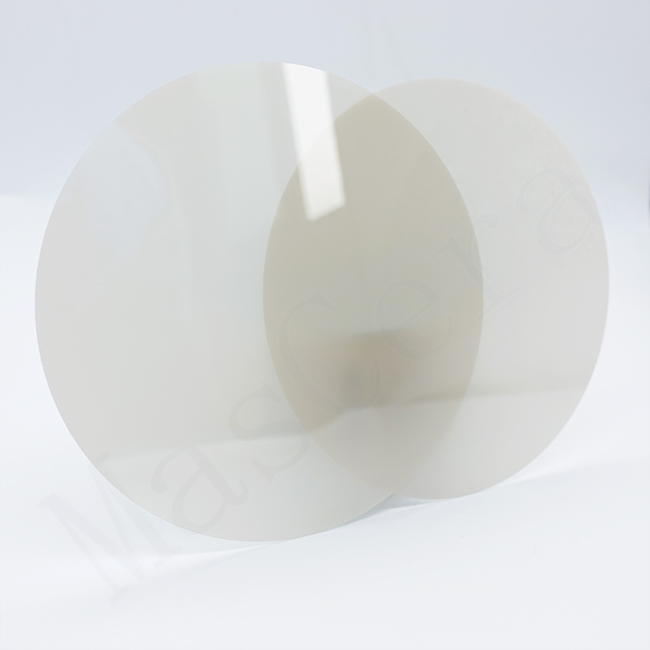

Aluminum Nitride AlN Ceramic Insulator Parts

- MSJ/ALN-006

- Aluminum Nitride Ceramic

- Customized

- 10 pcs per type

- Industrial Applications

Aluminum nitride ceramic insulator parts are high-performance ceramic products made primarily from aluminum nitride (AlN). Aluminum nitride ceramics exhibit high thermal conductivity, excellent electrical insulation, good thermal and chemical stability, as well as high strength and hardness. These properties make aluminum nitride ceramics widely applicable in various industries, including electronic & electrical, semiconductor, military, aerospace, automobile etc.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product Details

Aluminum nitride ceramic insulator parts are high-performance ceramic products made primarily from aluminum nitride (AlN). Aluminum nitride ceramics exhibit high thermal conductivity, excellent electrical insulation, good thermal and chemical stability, as well as high strength and hardness. These properties make aluminum nitride ceramics widely applicable in various industries, including electronic & electrical, semiconductor, military, aerospace, automobile etc.

Mascera offers a variety of aluminum nitride ceramic insulator parts to meet diverse customer needs. Our products are exported worldwide and have earned the trust and praise of global clients. We welcome custom designs and look forward to cooperating with you.

Material Characteristics

Aluminum nitride ceramics have the following notable features:

High Thermal Conductivity

Excellent heat transfer properties make it suitable for applications requiring effective heat dissipation.

High Electrical Insulation

Good electrical insulation properties make it an ideal material for electronic devices and high-voltage equipment.

High Hardness and Strength

Comparable to steel in hardness, with superior mechanical strength, allowing it to withstand heavy loads and harsh working conditions.

High-Temperature Resistance

Maintains stable physical and chemical properties under high temperatures, resistant to deformation, degradation, and oxidation.

Wear Resistance

Outstanding wear resistance, suitable for harsh conditions involving high speed, high temperature, and high pressure.

Application Areas

Aluminum nitride ceramic insulator parts have a broad range of applications, including:

Aerospace Industry

Used in manufacturing high-temperature parts, combustion chambers, and engine components.

Military Industry

Applied in the production of armored vehicles, gun barrels, missile components, etc.

Electronics and Information Technology

Utilized in making heat sinks, packaging materials, and high-frequency devices.

Mechanical Manufacturing

Employed in the production of bearings, cutting tools, molds, etc.

Energy Sector

Used in manufacturing gas turbines and solar mirrors.

Chemical Industry

Applied in producing corrosion-resistant equipment and pumps and valves.

Material Data Sheet

| ITEMS | UNIT | PARAMETER |

|---|---|---|

| Al2O3 Purity | % | 95 |

| Color | ‐ | Light Grey |

| Density | g/cm3 | ≥3.3 |

| Water Absorption | % | 0 |

| Moh’s Hardness | ‐ | 8 |

| Flexural Strength(at 25℃) | Mpa | 365-420 |

| Compressive Strength(at 25℃) | Mpa | 310-320 |

| Thermal Conductivity | W/m.k | ≥170 |

| Coefficient of Thermal Expansion(20~300℃) | 10‐6/℃ | 4.6 |

| Max working temperature | ℃ | 1800 |

| Volume Resistivity | Ω.cm | 1013 |

| Dielectric Constant(1MHz, 25℃) | ‐ | 9 |

| Dielectric Loss(1MHz, 25℃) | ‐ | 3.8 X 10-4 |

| Dielectric Strength | KV/mm | 17 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |