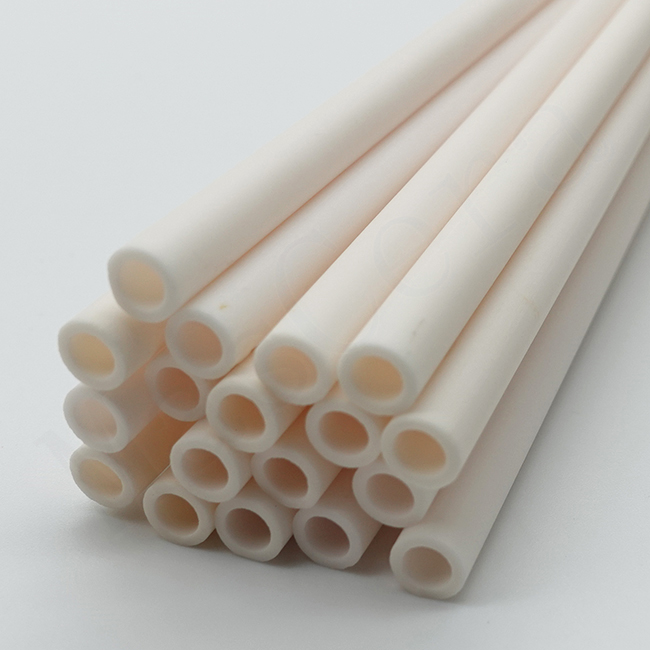

Alumina Ceramic Thermocouple Protection Tubes

- MSJ/HTCT-001

- 95% 99% 99.5% alumina ceramic

- customized

- 10 pcs per type

- ceramic protection tubes for thermocouples

Mascera is a professional supplier for technical ceramic parts, we provide custom manufacturing for alumina ceramics, zirconia ceramics, boron nitride ceramics, silicon nitride ceramics, silicon carbide ceramics, aluminum nitride ceramics and machinable glass ceramics.

We produce alumina ceramic tubes for different usage, such as ceramic furnace tube, ceramic thermocouple protection tube, multi-hole ceramic tubes for thermocouple, ceramic square tubes for corona machines etc.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

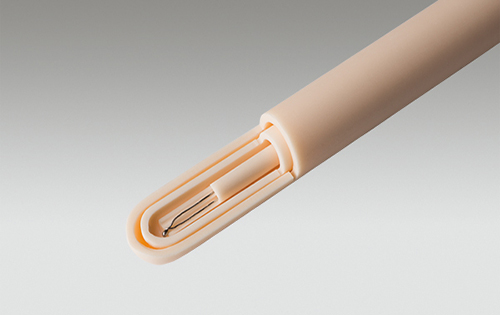

Alumina ceramic, also known as Al2O3 or aluminum oxide ceramic, finds extensive application in high-temperature environments due to its excellent resistance to elevated temperatures. It possesses remarkable thermal stability, withstanding temperatures up to 1800℃. In addition to its stable chemical properties, it offers high mechanical strength and electrical insulation capabilities. Alumina ceramic is commonly used for manufacturing ceramic tubes for high-temperature furnaces, closed-end ceramic tubes or multi-hole insulating rods for thermocouples, and square ceramic tubes for corona electrodes.

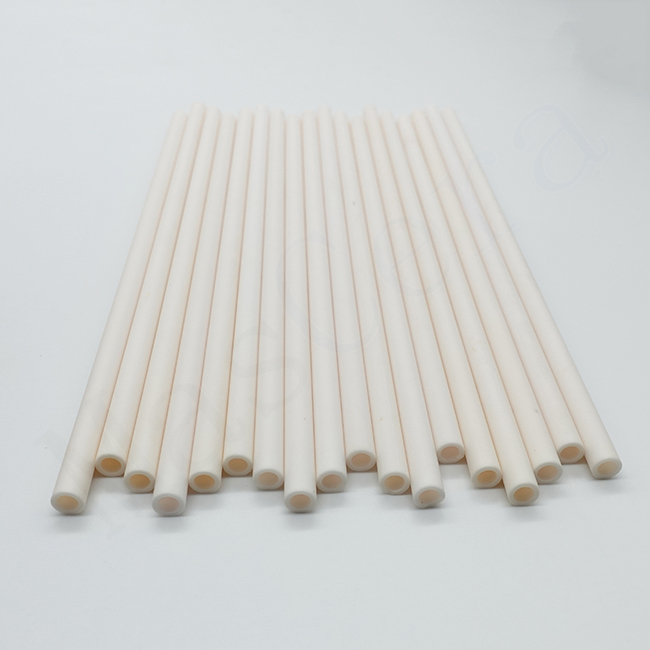

At Mascera, we utilize extrusion molding technology to produce ceramic tubes up to 2000mm in length. Custom sizing options are available, and we encourage you to reach out to us with your specific requirements.

Material:95% / 99% / 99.5% alumina ceramic (C795 / C799)

Available shapes:Round tubes, square tubes, or custom shapes

Available size: Outer diameter 0.7-200mm, Inner diameter 0.3-190mm, length up to 2000mm

Usage of tubes:

1)Thermocouple protection tubes(one end closed, single hole)

2)Ceramic furnace tube (open both ends, single hole)

3)Ceramic insulting rods for thermocouples (open both ends, single hole/double holes/four holes/multi holes)

4)Square ceramic tubes for corona electrode

Product Feature

High mechanical strength and hardness

Extreme wear resistance

Good electrical insulation

Low dielectric constant and dielectric loss

Excellent corrosion resistance

Good resistance to high temperature

Material Data Sheet

Item | Unit | Technical Parameter | ||

Al2O3 purity | % | 95 | 99 | 99.5 |

Color | --- | White | Ivory | Ivory |

Density | g/cm3 | 3.75 | 3.8 | 3.88 |

| Straightness | --- | 1.5‰ | 1.5‰ | 1.5‰ |

Moh’s hardness | --- | 9 | 9 | 9 |

Water absorption | % | 0.01 | 0.01 | 0.01 |

Flexural strength | Mpa | 300 | 340 | 375 |

Thermal conductivity (@R.T.) | W/mk | 16 | 24 | 25 |

Thermal expansion coefficient (25-1000℃) | 10-6/℃ | 7.6 | 7.6 | 7.6 |

Maximum temperature for long time working | ℃ | 1450 | 1600 | 1650 |

Refractory temperature | ℃ | 1650 | 1750 | 1800 |

Dielectric Sstrength | Kv/mm | 16 | 19 | 20 |

Electrical resistivity (@R.T.) | Ω.cm | 1014 | 1014 | 1014 |

Dielectric constant (1MHz, R.T.) | --- | 9 | 9.5 | 9.7 |

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |

Company Introducton

XIAMEN MASCERA TECHNOLOGY CO., LTD. is a China supplier which specialized in custom manufacturing of technical ceramic components. We provide a broad range of high performance ceramic materials including alumina ceramic, zirconia ceramic, silicon nitride ceramic, silicon carbide ceramic, boron nitride ceramic and aluminum nitride ceramic.

Our production facility is equipped with state-of-the-art production lines for molding, sintering, high-precision machining, and quality inspection of technical ceramic components. We follow the ISO9001:2015 quality management system, ensuring that our products meet the highest standards of quality. We take pride in our ability to deliver fully dense ceramic components with accurate sizing and surface finish control in a timely manner.

At Mascera, we have always been dedicated to providing the highest quality ceramic components and establishing strong partnerships with our customers. Our products have been exported to 40 countries and have found widespread use in industries such as machinery, automotive, chemistry, medical, energy, electronics, semiconductors, aerospace, and telecommunications.

Leveraging our expertise in material properties and machining techniques, we offer our customers valuable solutions for their specific applications and collaborate with them from prototype development to mass production. It is a great honor that some research institutes and high-tech enterprises use our technical ceramic components, contributing to technological innovation.