Boron Nitride Ceramic Rod

- MSJ/BN-004

- hot pressed boron nitride (HBN)

- customized

- 10 pcs per type

- industrial applications

Boron nitride rods are produced by high-temperature vacuum hot-press sintering of powdered hexagonal boron nitride. They exhibit excellent resistance to high temperatures, remarkable chemical stability, high electrical insulation properties, and strong resistance to corrosive acids. One unique characteristic of boron nitride rods is their non-wetting properties with most molten metals, making them ideal for producing ceramic nozzles or crucibles for metal smelting applications. In contrast to alumina ceramic or zirconia ceramic, boron nitride rods have a low hardness and excellent machinability, allowing for easy machining using common metalworking tools.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

Boron nitride rods are produced by high-temperature vacuum hot-pressing sintering of powdered hexagonal boron nitride (HBN). These rods are characterized by their good resistance to high temperatures, extremely stable chemical properties, resistance to strong acid corrosion, and high electrical insulation properties. One of the most unique features of boron nitride rods is their non-wetting property with most molten metals, which makes them ideal for producing ceramic nozzles or crucibles for metal smelting applications. Compared to alumina ceramic or zirconia ceramic, boron nitride rods have low hardness and excellent machinability, making them easy to machine with common metal working tools.

Mascera is a reputable supplier of boron nitride rods, with a maximum length of up to 480mm. To meet the diverse property requirements of our customers, we offer several grades of boron nitride ceramics, including regular 99% boron nitride ceramic, as well as boron nitride ceramics composited with zirconia ceramic, aluminum nitride, silicon carbide, and alumina ceramic. If you have any inquiries, please don't hesitate to contact us via email at info@mascera-tec.com or call us at +86 13860446139.

Main properties of boron nitride rods

Low density

High electrical resistivity

High breakdown voltage resistance

High thermal conductivity

Low thermal expansion coeffient

Good thermal shock resistance

High working temperature in vacuum and gas protection condition

Good corrosion resistance

Non-wetting with metals (without oxidization)

Good Machinability

Typical applications of hot pressed boron nitride

High temperature furnace fixtures and supports

Nozzles for metal powder gas atomization

Nozzle for amorphous soft magnetic

Plasma arc insulators

Crucibles or containers for metals or glasses smelting

Break rings for continuous casting of metals

Electrical insulators for high temperature vacuum equipment

Electrical insulator for PVD/CVD vacuum coating equipment

Electrical insulator for semiconductor equipment

Thermocouple protection tubes

Material Data Sheet

| Material Type | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E |

|---|---|---|---|---|---|---|---|

Main Content | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN |

Color | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green |

Density (g/cm3) | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 |

Flexural Strength (Mpa) | 18 | 30 | 65 | 65 | 80 | 90 | 90 |

Compressive Strength (Mpa) | 45 | 85 | 145 | 145 | 175 | 220 | 220 |

Electrical Resistivity (Ω.Cm) | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 |

Max. Service Temp. (℃) @Air Condition | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. (℃) @Vacuum Condition | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 |

Max. Service Temp. (℃) @Inert Gas Condition | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 |

Thermal Conductivity (W/Mk) | 35 | 40 | 35 | 35 | 45 | 30 | 85 |

Thermal Expansion Coefficient (25 - 1000℃) (10-6/K) | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 |

Performance comparison of boron nitride ceramics and alumina ceramics:

Compared with alumina ceramics, boron nitride ceramics have the following advantages:

1.Boron nitride ceramics can work under atmosphere protection at a maximum temperature of up to 2100 degrees, which is higher than that of alumina ceramics that cannot exceed 1700 degrees.

2.Boron nitride ceramics exhibit much better thermal shock resistance than alumina ceramics. For example, boron nitride ceramics will not crack under rapid temperature changes, and even after being taken out of a 1000 Celsius degree furnace and subjected to continuous blowing and quenching for 100 times, it will still not crack. On the other hand, alumina ceramics are prone to cracking under quick temperature changes.

3.The electrical insulation strength of boron nitride ceramics is 3-4 times higher than that of alumina ceramics.

4.Boron nitride ceramics do not react or bond with molten glasses or metals, making them ideal for use as containers for high-temperature sintering or melting crucibles, setter plates, and other applications.

Compared with alumina ceramics, the disadvantages of boron nitride ceramics are:

1. The strength, hardness and wear resistance of boron nitride ceramics are lower than that of alumina ceramic, and it is not suitable for use under vibration and friction conditions.

2. The use temperature of boron nitride ceramics in the air is only 1000 celsium degrees, and it will oxidize if it exceeds 1000 degrees.

Available shapes of hot pressed boron nitride

Ceramic rod / ceramic pin

Ceramic tube / ceramic bushing / ceramic sleeve

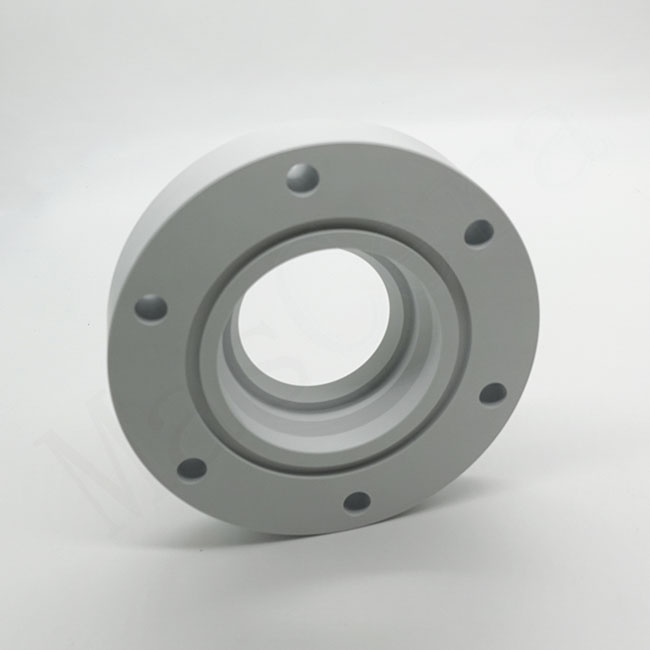

Ceramic ring / ceramic washer / ceramic spacer

Ceramic disc

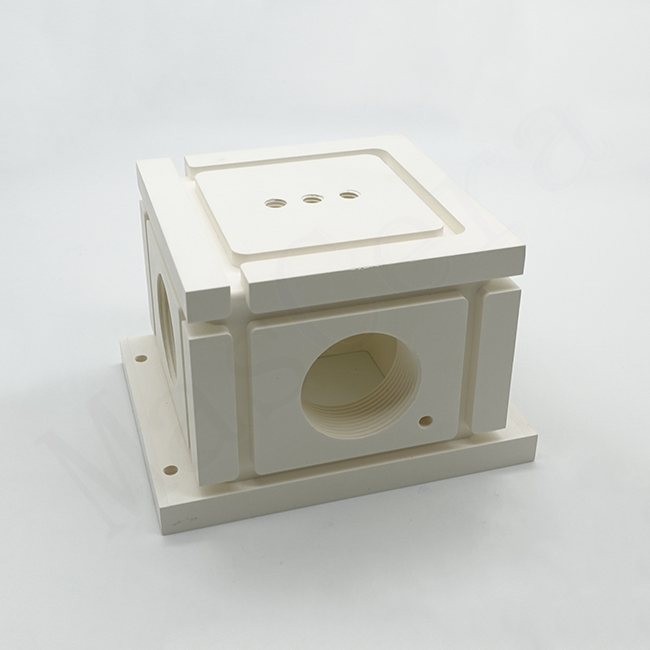

Ceramic plate / ceramic block

Ceramic nozzle

Ceramic crucible

Other custom ceramic parts

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |