Boron Nitride Composite Evaporation Boat for Vacuum Deposition Coating

- MSJ/BN-015

- boron nitride ceramic

- customized

- 5 pcs per type

- Vacuum Deposition Coating

The evaporation boat used in mascara production is made of a composite material of titanium diboride and boron nitride. Boron nitride composite evaporation boats are advanced evaporation vessels in the vacuum coating industry, known for their long lifespan, uniform evaporation, stable performance, and ease of use. They are widely used in industries such as packaging coating, color cathode ray tubes, and electronics, and have completely replaced older-generation products like graphite crucibles.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

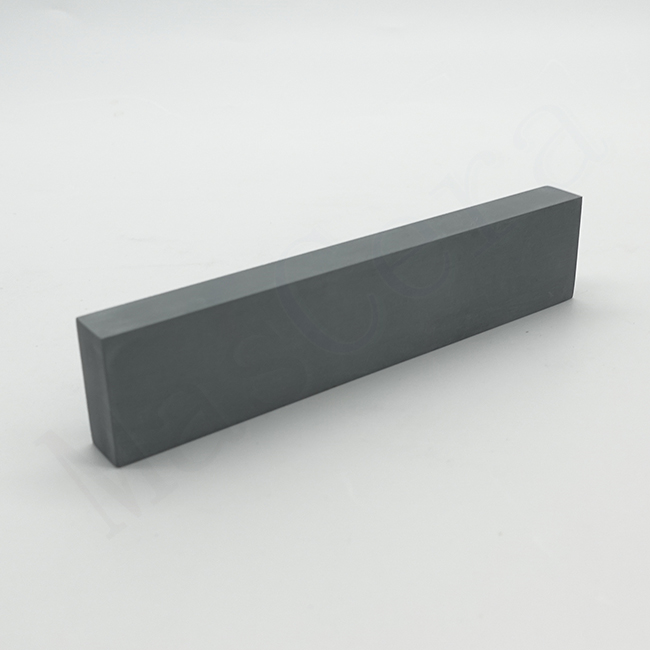

The evaporation boat used in mascara production is made of a composite material of titanium diboride and boron nitride. The raw material blocks are mechanically cut into different sizes according to customer requirements and then ground to create grooves of specific dimensions on the boat's surface. The boat has a gray, bar-like shape with internal grooves. The purpose of the grooves is to prevent the evaporated liquid from overflowing when the vacuum coating temperature reaches high levels. Boron nitride composite evaporation boats are advanced evaporation vessels in the vacuum coating industry, known for their long lifespan, uniform evaporation, stable performance, and ease of use. They are widely used in industries such as packaging coating, color cathode ray tubes, and electronics, and have completely replaced older-generation products like graphite crucibles.

Performance characteristics:

1. Excellent oxidation resistance, resistant to corrosion from metals such as aluminum, nickel, and gold, preventing liquid overflow during evaporation.

2. High-purity product with stable chemical properties and consistent electrical resistivity.

3. Can withstand high temperatures up to 1800°C.

Material Data Sheet

| Material Type | BN+TIB2 |

| Density(g/cm*3) | 3.05-3.15 |

| Compressive Strength(Mpa) | 190-200 |

| Flexural Strength(Mpa) | 110-140 |

| Shore hardness(HSD) | 35-40 |

| Thermal Conductivity(W/m·K) | 25-30 |

| Electrical Conductivity(S/m) | (0.85-0.90) * 10^5 |

Tips for Using

1.Working temperature in the air should not exceed 900℃, oxidation will occur when more than 900°C.

2.The components shall be stored in the dry environment inside a sealed container.

3.Never wash the component with water. Use fine sandpaper or cloth to remove any dirts or residues.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |