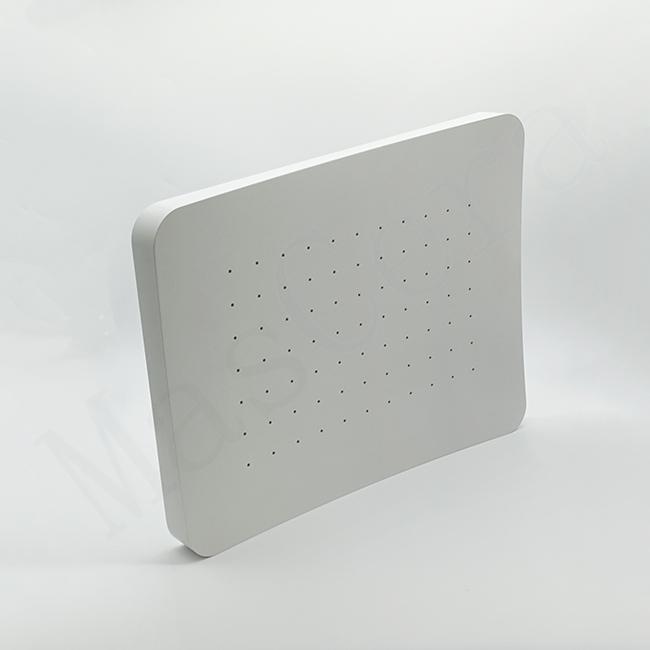

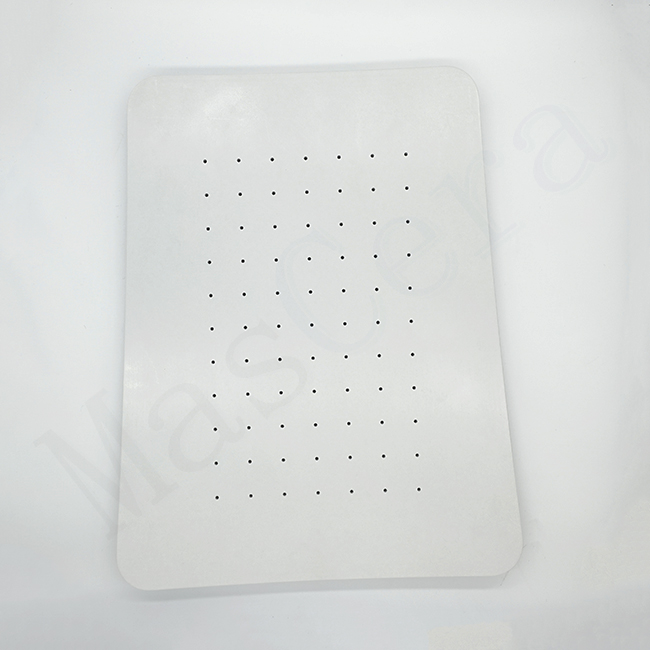

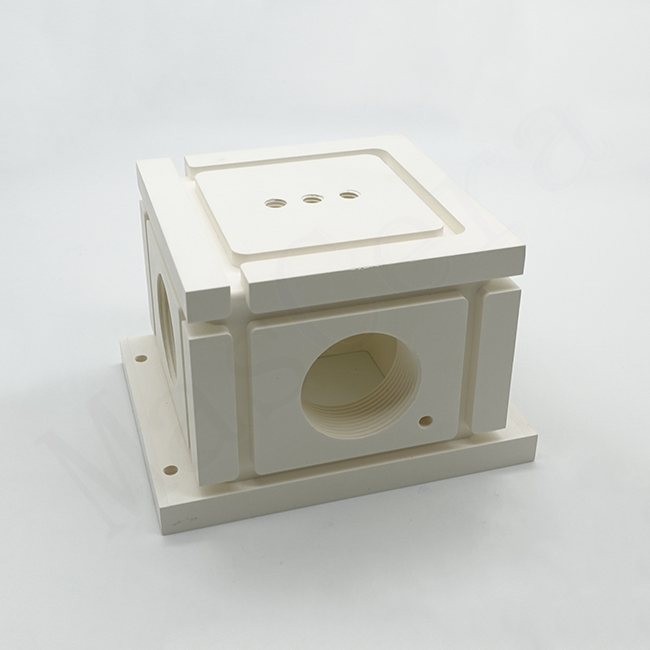

HBN boron nitride plate for precision glass molding

- MSJ/BN-014

- boron nitride ceramic

- customized

- 5 pcs per type

- Precision glass molding

A hot-pressed hexagonal boron nitride (hBN) mold by Mascera, designed for precision glass production.With high temperature resistance, low adhesion, and stable dimensions, these molds outperform traditional graphite. Experience extended lifespan, improved efficiency, and enhanced mold stability. Upgrade your glass manufacturing process with our advanced hBN molds, minimizing defects and optimizing mold release.

Any inquiry please email info@mascera-tec.com or call +86 13860446139

Product detail

In traditional glass production, graphite is commonly used as a mold material, but it has the following disadvantages: it is prone to wear and oxidation at high temperatures, reducing its lifespan; it has a high coefficient of thermal expansion, resulting in instability in mold precision and dimensions, requiring more frequent adjustments; the surface of graphite has adsorptive properties, leading to adhesion of glass to the mold; in extreme conditions, it has low strength and durability, lacking sufficient strength and durability for high-pressure or high-impact glass molding processes. Coating graphite molds with materials like boron nitride can improve their heat resistance and reduce adhesion, but there are still risks of coating detachment and shorter lifespan.

Hot-pressed hexagonal boron nitride (hBN) is suitable for molds in the production of precision glass products due to the following properties:

1. High temperature resistance: Hexagonal boron nitride can maintain structural stability in high-temperature environments, enabling molds to withstand the thermal stress of high-temperature glass melting and shaping processes, thereby extending their lifespan.

2. Low adhesion: Boron nitride surfaces have low adhesion, reducing the adhesion and retention of glass to the mold. This helps improve production efficiency and reduce the frequency of cleaning and maintenance.

3. Low coefficient of thermal expansion: Hexagonal boron nitride exhibits relatively stable dimensions at high temperatures, facilitating mold size stability and precision control.

4. High chemical inertness: Boron nitride can resist corrosion and chemical erosion, prolonging the mold's lifespan.

With advancements in hot-pressed boron nitride technology, it has become an ideal material for glass mold production, reducing surface defects, extending mold lifespan, and facilitating mold release.

Main properties

|

|

Material Data Sheet

| Material Type | BN-997 | BN-99 | BN-A | BN-B | BN-C | BN-D | BN-E |

|---|---|---|---|---|---|---|---|

Main Content | BN>99.7% | BN>99% | BN+AL+SI | BN+ZR+AL | BN+SIC | BN+ZRO2 | BN+AlN |

Color | White | White | Light Grey | Light Grey | Grey Green | Dark Grey | Grey Green |

Density (g/cm3) | 1.6 | 1.95-2.0 | 2.2-2.3 | 2.25-2.35 | 2.4-2.5 | 2.8-2.9 | 2.8-2.9 |

Flexural Strength (Mpa) | 18 | 30 | 65 | 65 | 80 | 90 | 90 |

Compressive Strength (Mpa) | 45 | 85 | 145 | 145 | 175 | 220 | 220 |

Electrical Resistivity (Ω.Cm) | >1014 | >1014 | >1013 | >1013 | >1012 | >1012 | >1013 |

Max. Service Temp. (℃) @Air Condition | 900 | 900 | 900 | 900 | 900 | 900 | 900 |

Max. Service Temp. (℃) @Vacuum Condition | 1800 | 1800 | 1750 | 1750 | 1800 | 1800 | 1750 |

Max. Service Temp. (℃) @Inert Gas Condition | 2100 | 2100 | 1750 | 1750 | 1800 | 1800 | 1750 |

Thermal Conductivity (W/Mk) | 35 | 40 | 35 | 35 | 45 | 30 | 85 |

Thermal Expansion Coefficient (25 - 1000℃) (10-6/K) | 1.5 | 1.8 | 2.0 | 2.0 | 2.8 | 3.5 | 2.8 |

Tips for Using

1.Working temperature in the air should not exceed 900℃, oxidation will occur when more than 900°C.

2.The components shall be stored in the dry environment inside a sealed container.

3.Never wash the component with water. Use fine sandpaper or cloth to remove any dirts or residues.

Packing & Shipment

| Package type | carton box with foam protection |

| Payment terms | TT / Western Union / Paypal 50% payment in advanced and 50% before shipment |

| Loading port | Xiamen, China |

| Shipping way | By sea / air / door-to-door express |